Bridge line shape detection method based on opposite side height difference measurement

A detection method and height difference technology, applied in the direction of height/level measurement, measuring instruments, measuring devices, etc., can solve problems such as difficult automation, difficult traffic suspension, and hidden safety hazards, so as to improve work efficiency, improve measurement accuracy, and reduce measurement the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

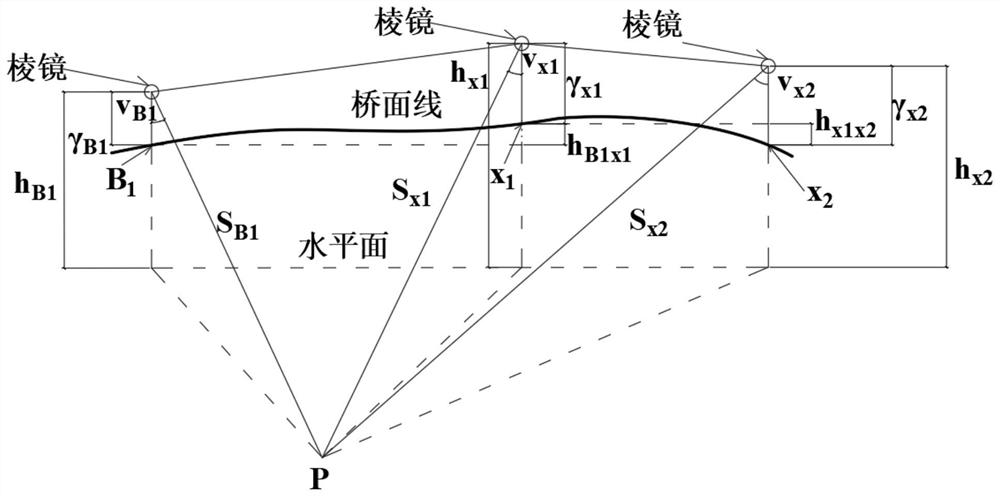

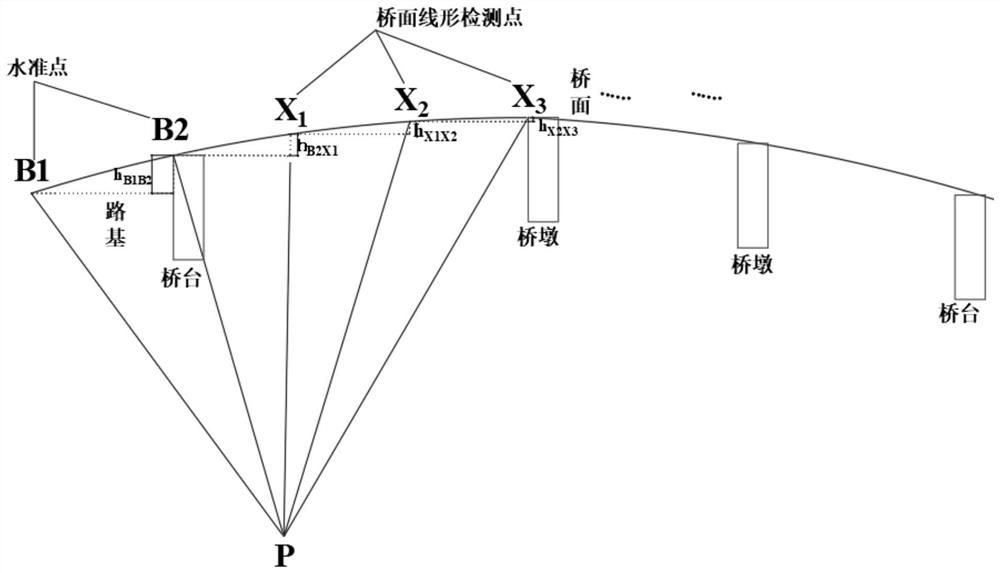

[0046] Such as Figure 1-2 As shown, this embodiment provides a bridge alignment detection method based on the measurement of the height difference between opposite sides. Three detection points are set on the bridge surface, and the steps are as follows:

[0047] S1. Set the benchmark point B on the stable ground other than the bridge (other than 0# platform) 1 , B 2 , set the alignment detection point X on the bridge surface 1 、X 2 and x 3 , set P as a free station, install a total station at point P, and place a total station at point B 1 and detection point X 1 、X 2 、X 3 Set up prisms on the top, observe point P to benchmark point B 1 and detection point X 1 、X 2 、X 3 The slope distance S B1 , S X1 , S X2 , S X3 And point P to benchmark point B 1 and detection point X 1 、X 2 、X 3 Zenith distance V B1 , V X1 , V X2 , V X3 , according to the formulas (1) and (2) to get the benchmark point B 1 to detection point X 1 height difference h B1X1 , detecti...

Embodiment 2

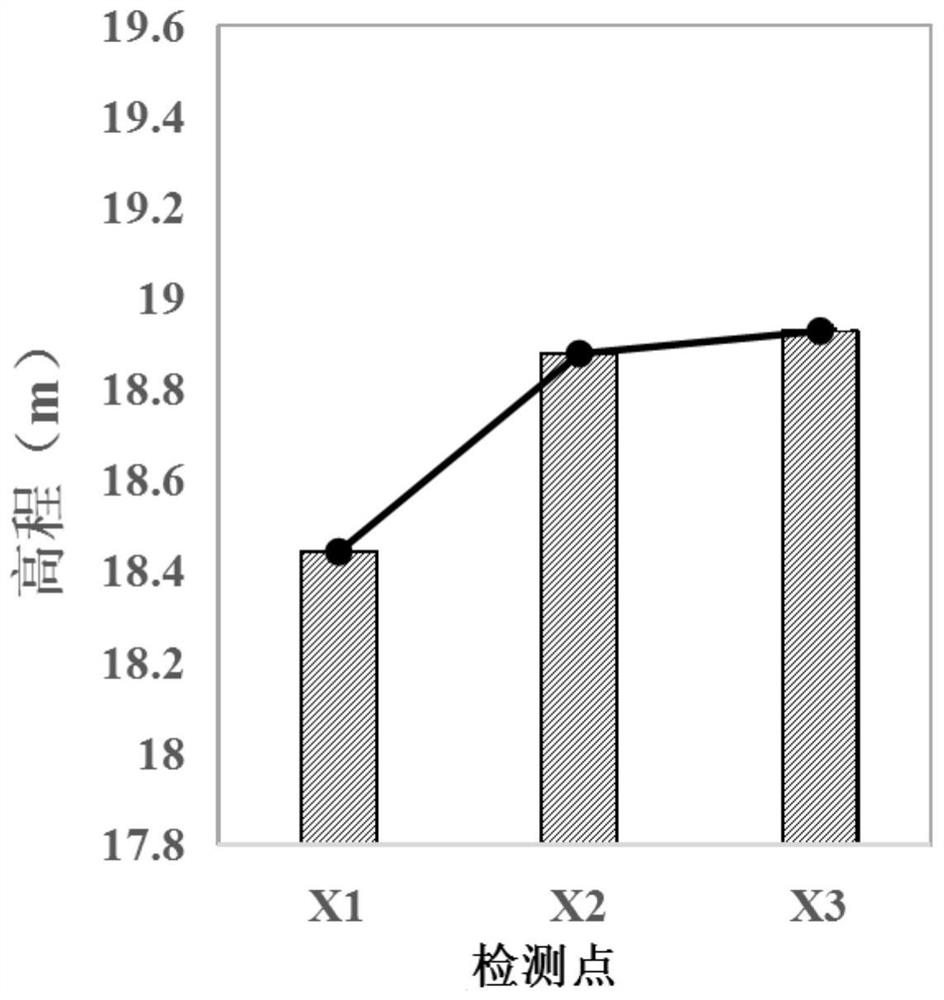

[0062] A bridge alignment observation method based on the height difference measurement of opposite sides, the steps are as described in Embodiment 1, the difference is that in step S4, the bridge deck elevation alignment curve is drawn in the following way: with the detection point as the abscissa, the detection point elevation is the ordinate, and the height of the detection point is marked with the height of the column, and the height of each detection point is connected by a broken line to visually display the measurement result;

[0063] The drawing method of the bridge deck elevation linear curve table is as follows: take each detection point as the header, and mark the corresponding elevation data in the lower row of the header.

[0064] The linear curve of the bridge deck elevation is as follows: image 3 As shown, the bridge deck elevation linear curve table is shown in Table 1;

[0065] Table 1: Bridge Deck Elevation Linear Curve Table

[0066] Monitoring...

Embodiment 3

[0075] A bridge alignment observation method based on the height difference measurement of opposite sides, the steps are as described in Embodiment 1, the difference is that in step S1, the inclination distance S B1 , S X1 , S X2 , S X3 and zenith distance V B1 , V X1 , V X2 , V X3 The observation precision adopts the third-class settlement observation trigonometric height measurement technology requirements: the error in the angle measurement of the first measurement round: ≤1.0", the error in the distance measurement ≤ (1.0mm+1.0ppm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com