Single-stage porous throttling orifice plate and throttling device

A technology of throttling orifice plate and orifice, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve problems such as loud noise and pipe vibration, reduce noise, improve flow field, and ensure sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

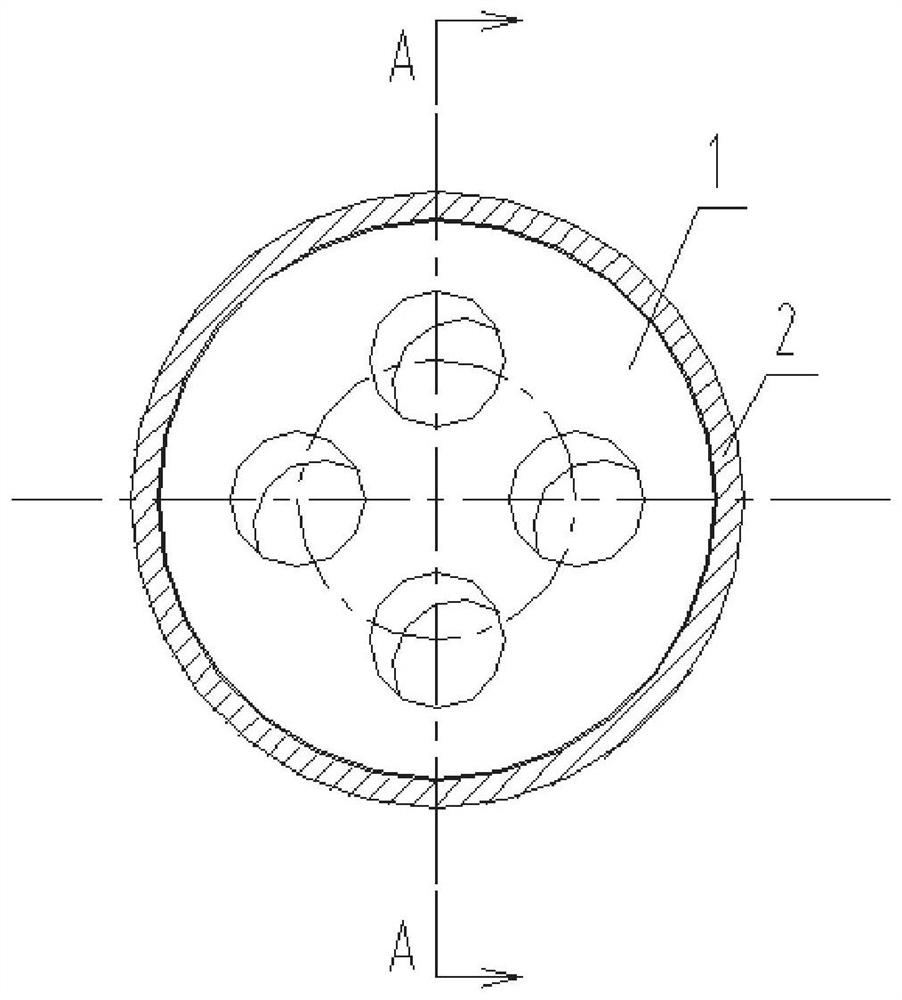

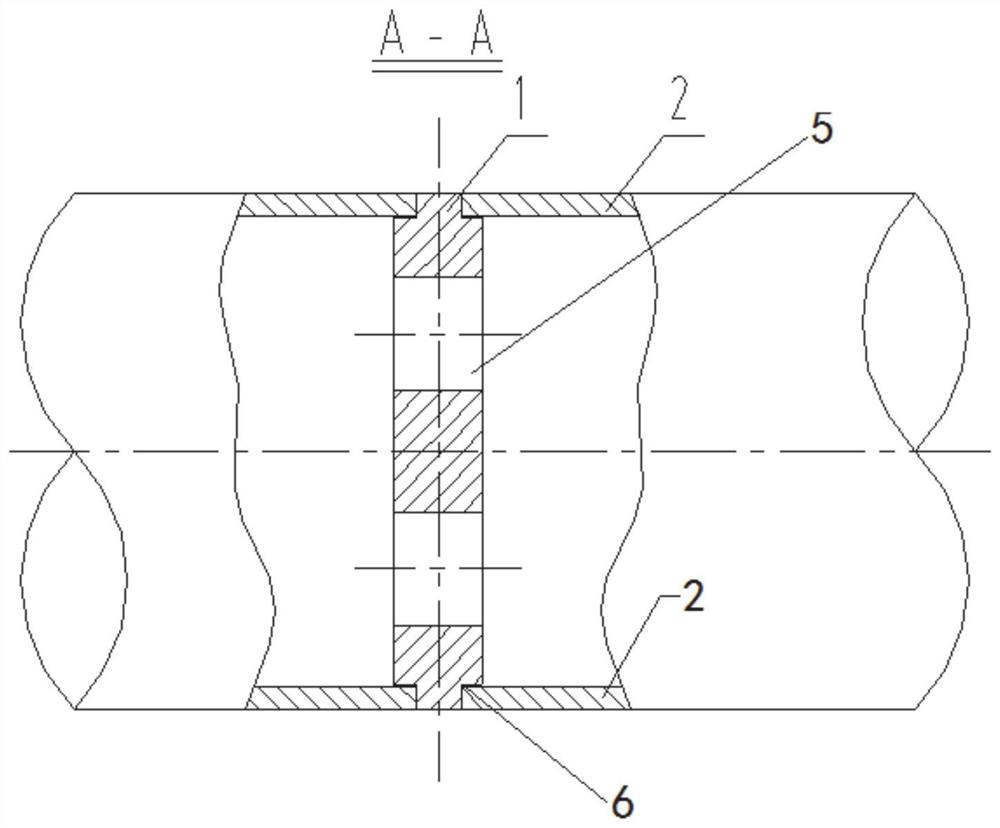

[0058] In a typical embodiment of the present invention, a single-stage multi-hole throttle orifice plate includes a plate body 1, the plate body 1 has a set thickness and the size of the plate body is adapted to the size of the pipeline 2, and the plate body 1 is opened There are at least two throttling holes 5, and a plurality of throttling holes 5 are arranged around the center axis of the plate body 1, or one of the throttling holes is arranged at the center of the plate body.

[0059] The above-mentioned single-stage multi-hole throttling orifice can be divided into two types: welding connection and flange clamping connection.

[0060] In this embodiment, for the throttling orifice plate connected by welding, in order to further ensure the cooperation between the plate body and the pipeline, refer to figure 1 with figure 2 As shown, the two ends of the board are provided with steps 6 in the circumferential direction, so that groove structures are formed on both ends of...

Embodiment 2

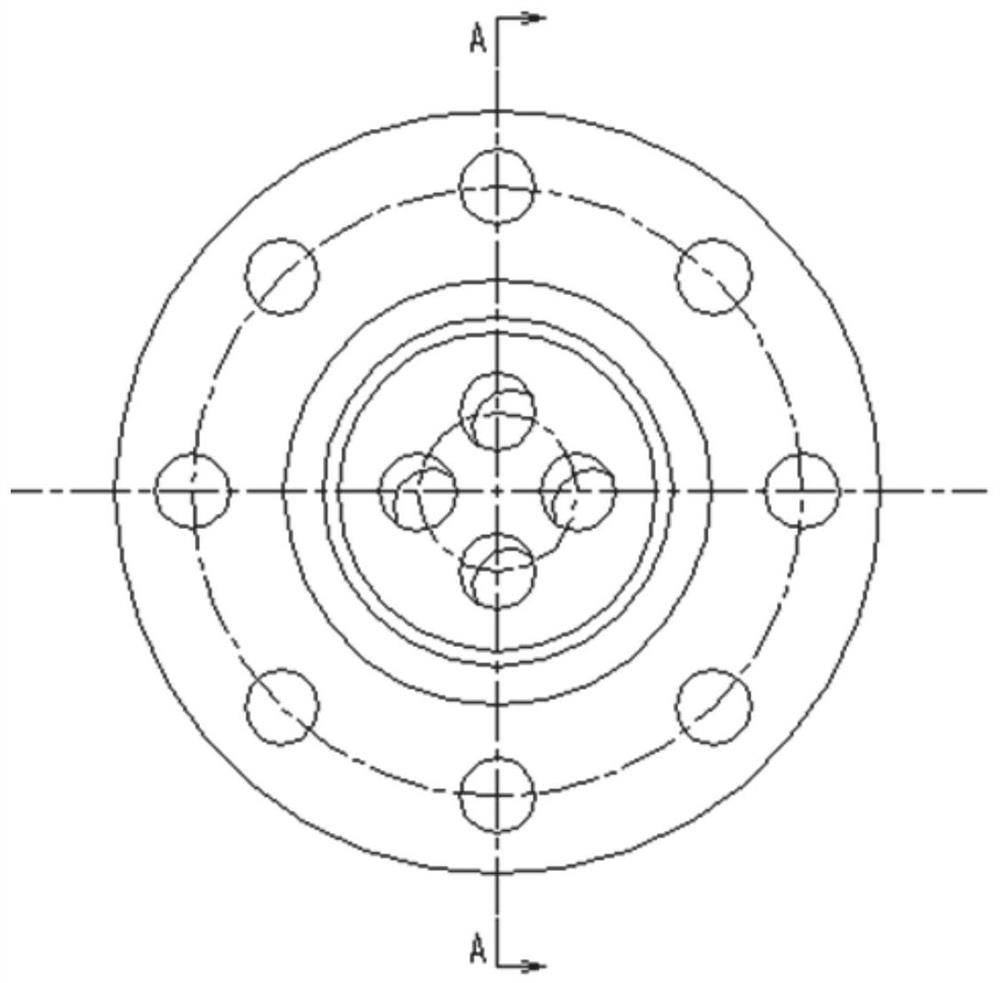

[0077] The difference between this embodiment and the first embodiment is that the throttle orifice is connected by flange clamping.

[0078] For flange clamp orifice installations, refer to image 3 with Figure 4 As shown, the diameter of the flange is larger than the diameter of the plate body, and the ends of the pipes are connected by flanges. A throttling orifice plate with a set thickness is arranged between the two flanges, and the diameter of the plate body is larger than that of the connecting flange with the same plate body That is the inner diameter of the pipe.

[0079] For the flange clamping connection method, the diameter of the plate body is larger than the inner diameter of the flange and correspondingly larger than the inner diameter of the pipe connected to the flange.

Embodiment 3

[0081] This embodiment provides a throttling device, including the single-stage multi-hole throttling orifice described in Embodiment 1 or Embodiment 2.

[0082] In some examples, a throttling device further includes flanges, the flanges can be connected to the pipeline, and the distance between the two flanges is set to prevent the flange contact from affecting the throttling effect of the throttling plate. (Adjacent side between two adjacent flanges) set a groove that can accommodate part of the throttle orifice, and accommodate the throttle orifice through the grooves of two adjacent flanges, so that the throttle orifice can be set in the groove The fit of the flange improves the reliability of the connection between the flange and the board.

[0083] The diameter of the groove is larger than the inner diameter of the pipe. Correspondingly, the size of the plate body is larger than the inner diameter of the pipe. Considering the convenience of the installation of the thrott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com