Vaccine production equipment

A vaccine production and equipment technology, applied in biochemical equipment and methods, biochemical instruments, biomass post-processing, etc., can solve the problems of inconvenient cleaning, fixed frame occupying workbench space, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

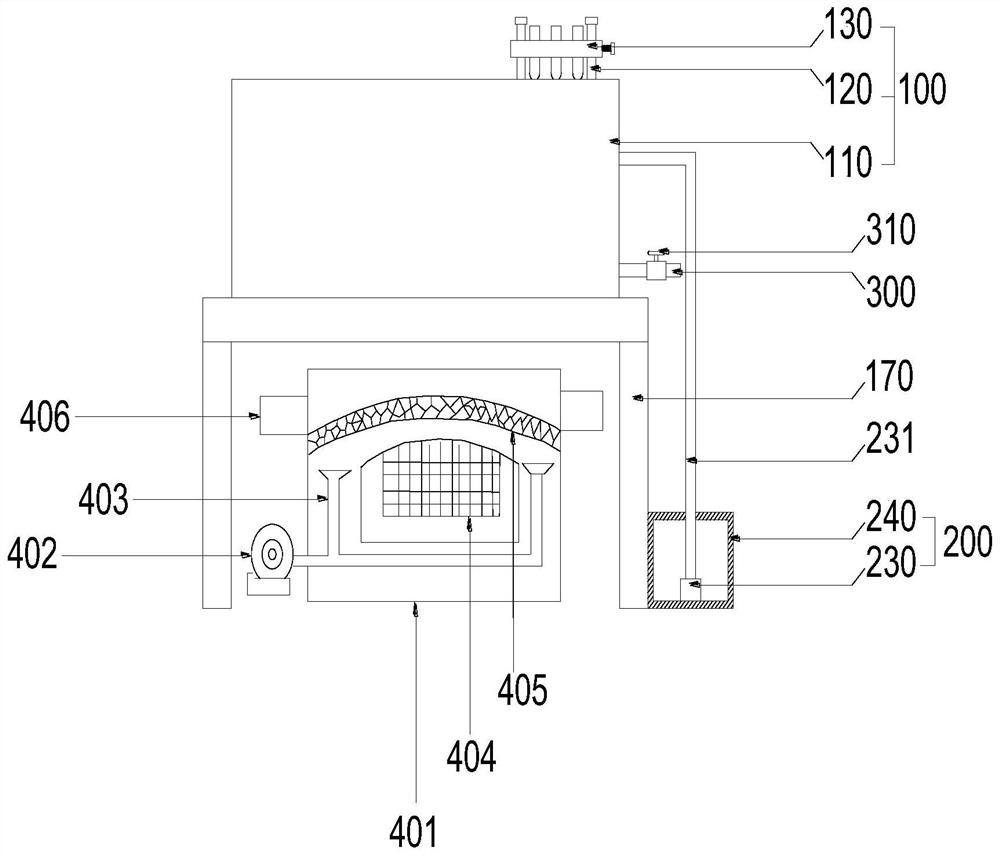

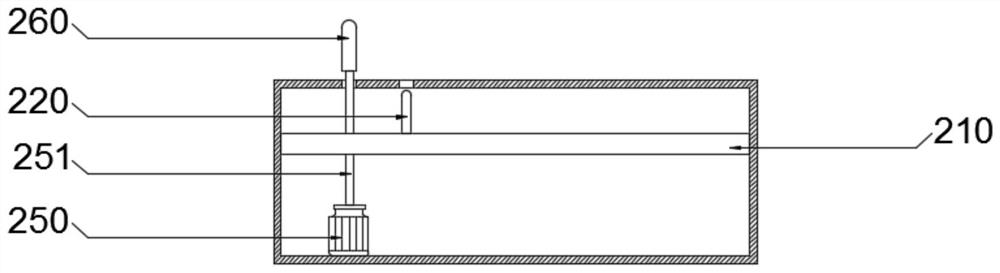

[0039] see figure 1, the present invention provides a technical solution: a vaccine production equipment includes a fixing mechanism 100 and a cleaning mechanism 200 , wherein the cleaning mechanism 200 is fixed in the fixing mechanism 100 .

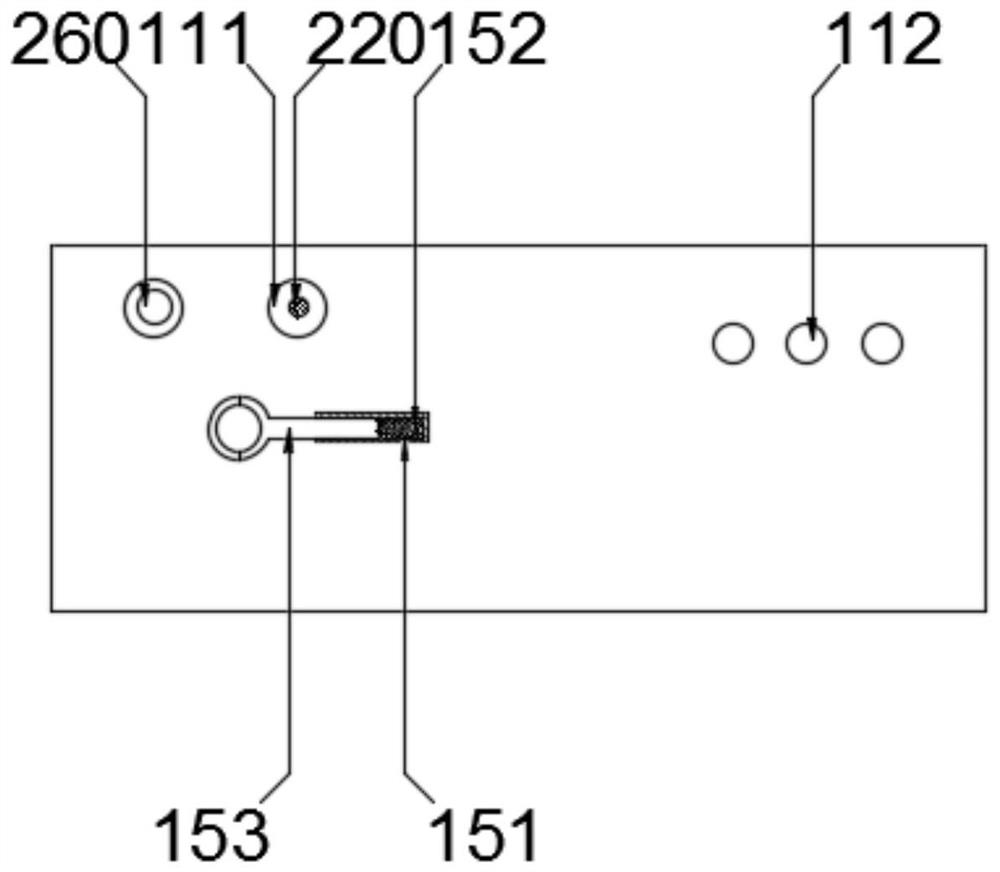

[0040] see figure 1 , 2 And 4, the fixing mechanism 100 includes a cleaning box 110, a first pole 120, a fixed plate 130, a test tube 140, a telescopic rod 150 and a block 160, and the surface of the cleaning box 110 is provided with three first through holes 111, the first through hole The diameter of 111 is larger than that of the test tube 140. There are two first support rods 120, and the two first support rods 120 are fixed on the surface of the cleaning box 110 at intervals. 112, the groove 112 is arranged under the test tube 140, the groove 112 is convenient for fixing the test tube 140, the fixing plate 130 is slidably sleeved on the first support rod 120, and the end of the first support rod 120 away from the cleaning box 110 ...

Embodiment 2

[0045] see figure 1 , the present invention provides a technical solution: a vaccine production equipment includes a fixing mechanism 100 and a cleaning mechanism 200 , wherein the cleaning mechanism 200 is fixed in the fixing mechanism 100 .

[0046] see figure 1 , 2 And 4, the fixing mechanism 100 includes a cleaning box 110, a first pole 120, a fixed plate 130, a test tube 140, a telescopic rod 150 and a block 160, and the surface of the cleaning box 110 is provided with three first through holes 111, the first through hole The diameter of 111 is larger than that of the test tube 140. There are two first support rods 120, and the two first support rods 120 are fixed on the surface of the cleaning box 110 at intervals. 112, the groove 112 is arranged under the test tube 140, the groove 112 is convenient for fixing the test tube 140, the fixing plate 130 is slidably sleeved on the first support rod 120, and the end of the first support rod 120 away from the cleaning box 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com