Electro-tricycle carriage with auxiliary loading structure,

A technology for electric tricycles and tricycles, which is applied to vehicles with wheels, vehicles used for freight, vehicles with loading ramps, etc., can solve the problems of increasing the work intensity of staff and inconvenient for staff to load and unload goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

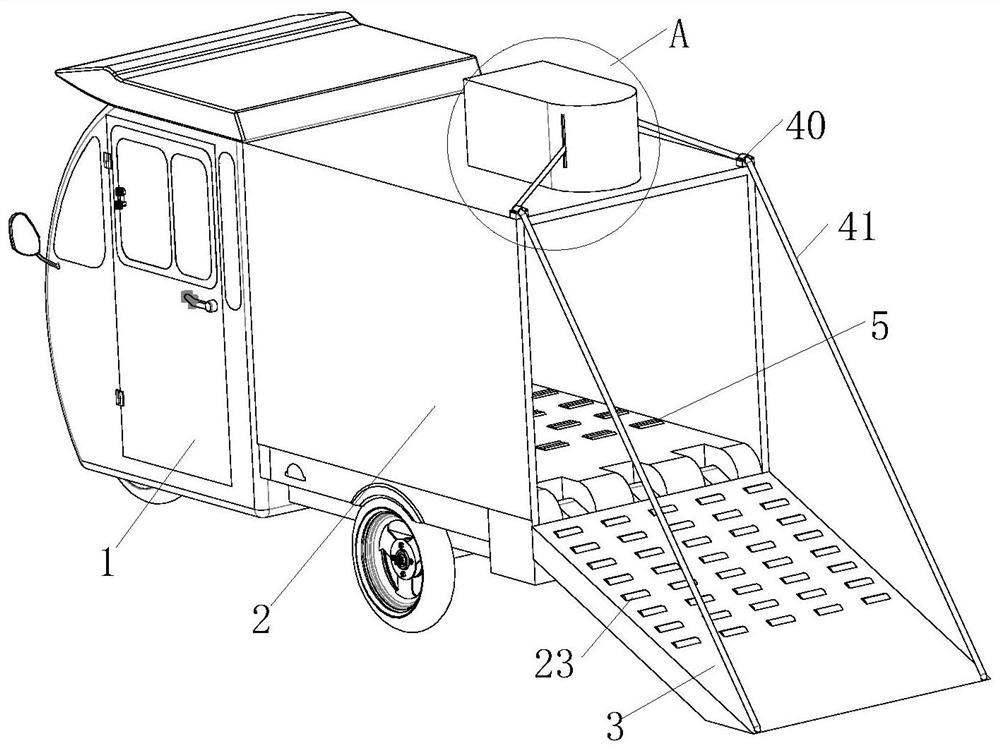

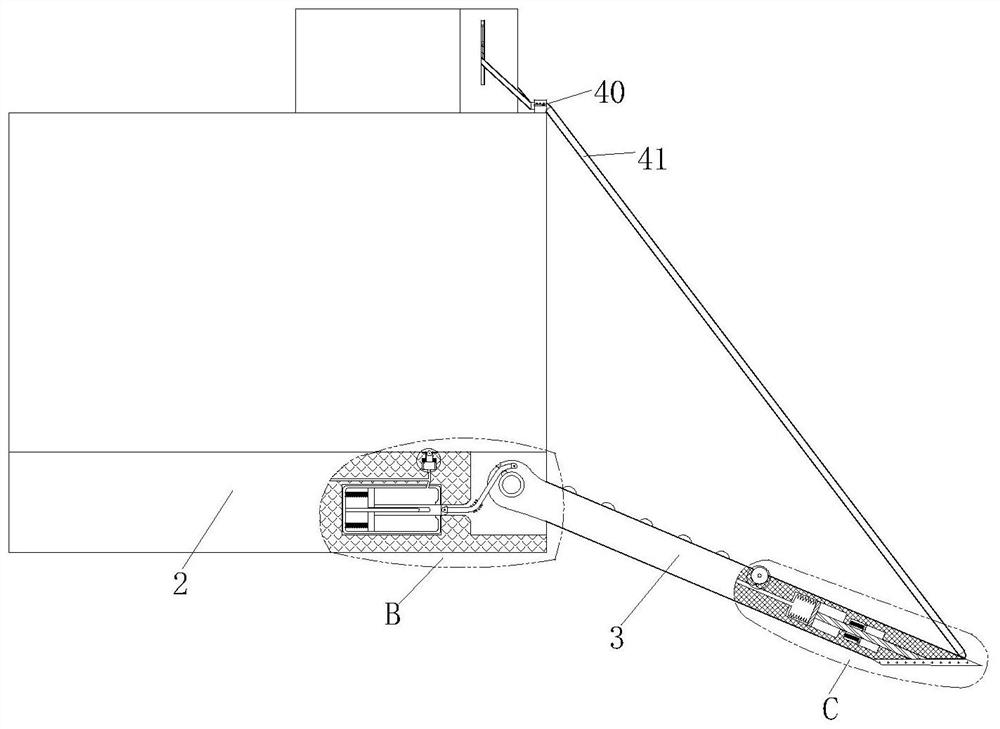

[0031] see Figure 1-7 As shown, an electric tricycle compartment with an auxiliary loading structure includes a tricycle body 1, a compartment 2, a rear plate 3, a hydraulic structure, a slide table 4 and rollers 5; the top surface of the tricycle body 1 is fixed to the compartment 2. The rear part of the compartment 2 is hinged to the rear panel 3, and a hydraulic structure is arranged inside the bottom wall of the compartment 2, and a plurality of lifting grooves 6 are evenly opened on the top surface of the bottom wall of the compartment 2, and the inside of the lifting groove 6 Slidingly install the sliding table 4, the top surface of the sliding table 4 is provided with a notch, the inside of the notch is rotated to install the roller 5, the power end of the hydraulic structure is connected to the hinge position of the rear plate 3, the execution of the hydraulic structure The end is connected to the bottom of the slide table 4; during work, the inner bottom surface of t...

Embodiment 2

[0041] see Figure 8 As shown, the outer ring of the piston 8 is provided with a plurality of ring grooves 42, the inside of the ring grooves 42 is fixedly connected with a sealing ring 43, the middle part of the sealing ring 43 is provided with a main air ring 44, and the middle part of the sealing ring 43 A plurality of auxiliary air rings 45 are arranged on the outer ring, and the auxiliary air rings 45 communicate with the main air ring 44; when working, the piston 8 and the hydraulic cylinder 7 squeeze the sealing ring 43, so that the sealing ring 43 is compressed and deformed, so that the main air ring 44 is compressed with the auxiliary air ring 45, so that the sealing ring 43 is closely attached to the inner wall of the hydraulic cylinder 7, preventing hydraulic oil from entering one side of the extension spring 12, thereby increasing the oil pressure of the hydraulic structure.

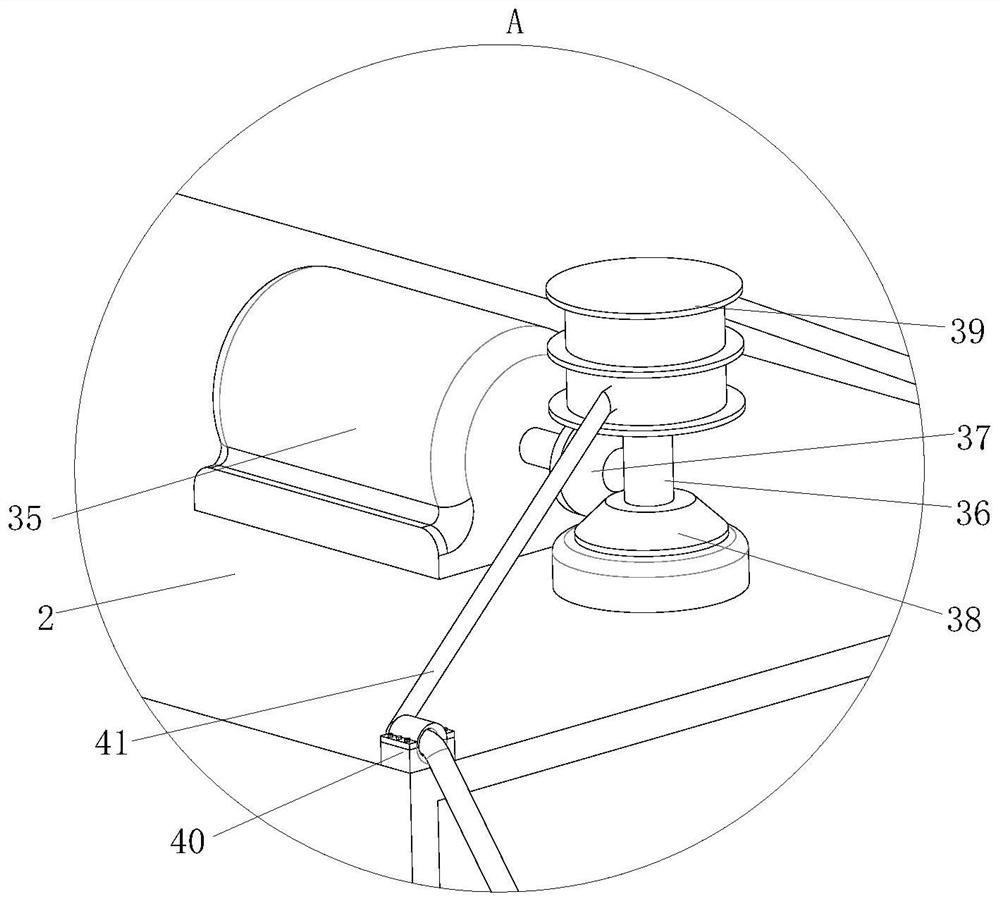

[0042] Working principle: First, the motor 35 rotates in the opposite direction, and thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com