Weldment cooling device for vacuum welding machining

A vacuum welding and cooling device technology, applied in auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of poor cooling effect, affecting the appearance, and unable to realize fixed-point cooling of welds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

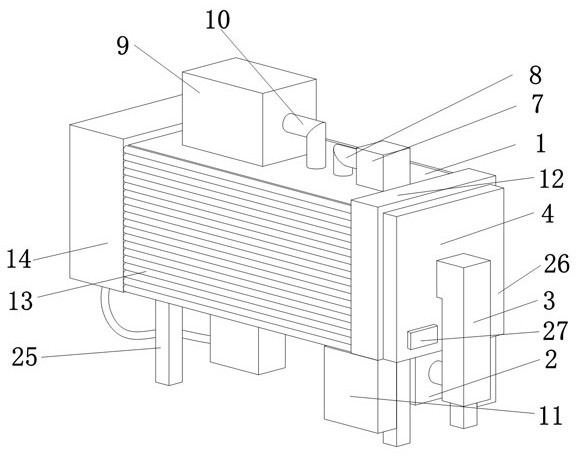

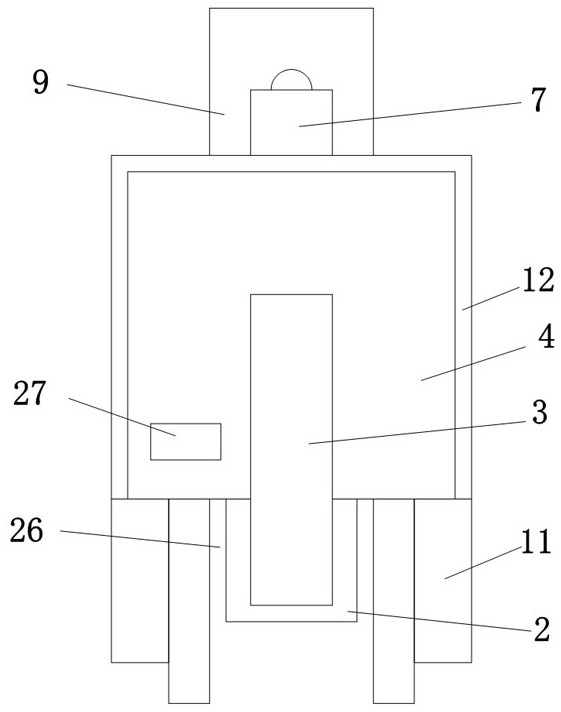

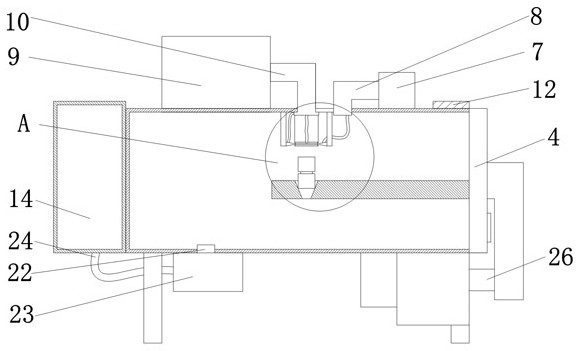

[0029] like Figure 1 to Figure 7 As shown, the present invention provides a welding piece cooling device for vacuum welding, comprising a vacuum box 1, one side of the vacuum box 1 is a feed port, the bottom of the vacuum box 1 is provided with a hydraulic connection device 26, and one part of the hydraulic connection device 26 is There is a sealed door 4 on the side, and the sealed door 4 is matched with the feed port. The opening of the sealed door 4 can realize the feeding of the inside of the vacuum box 1, and when the sealed door 4 and the vacuum box 1 are closed, the absolute inside of the vacuum box 1 is guaranteed. Airtight to prevent the outside air from entering the vacuum box 1 during the welding cooling process and causing pollution to the welding. The hydraulic connection device 26 includes a hydraulic cylinder 2, which is fixedly connected to the bottom of the vacuum box 1, and the output end of the hydraulic cylinder 2 is provided with a connection The rod 3 an...

no. 2 example

[0039] Based on the welding piece cooling device for vacuum welding processing provided in the first embodiment, only water cooling is used to cool the vacuum welding, the cooling efficiency is low, and the welding position cannot be cooled at a fixed point, and the molten solder 16 is solidified when it is solidified. Due to the different positions, the cooling efficiency of each part will be different, so that gaps and leaks will appear between the solidified solder 16 due to uneven cooling, which will affect the welding effect. When the common air cooling is used to cool the weld, Because the cooling gas blows the molten solder 16 by wind force to cause it to flow in all directions, or when the base material 15 and the solder 16 are tilted, the molten solder 16 will flow obliquely under its own gravity, thereby The welding position is uneven, which reduces the welding effect and affects the aesthetics of the welding. At the same time, the cooling liquid and cooling gas after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com