Screening device for lithium battery recycling based on machine vision

A machine vision and screening device technology, applied in sorting and other directions, can solve problems such as restricting the development of lithium battery recycling technology, and achieve the effect of facilitating recycling and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

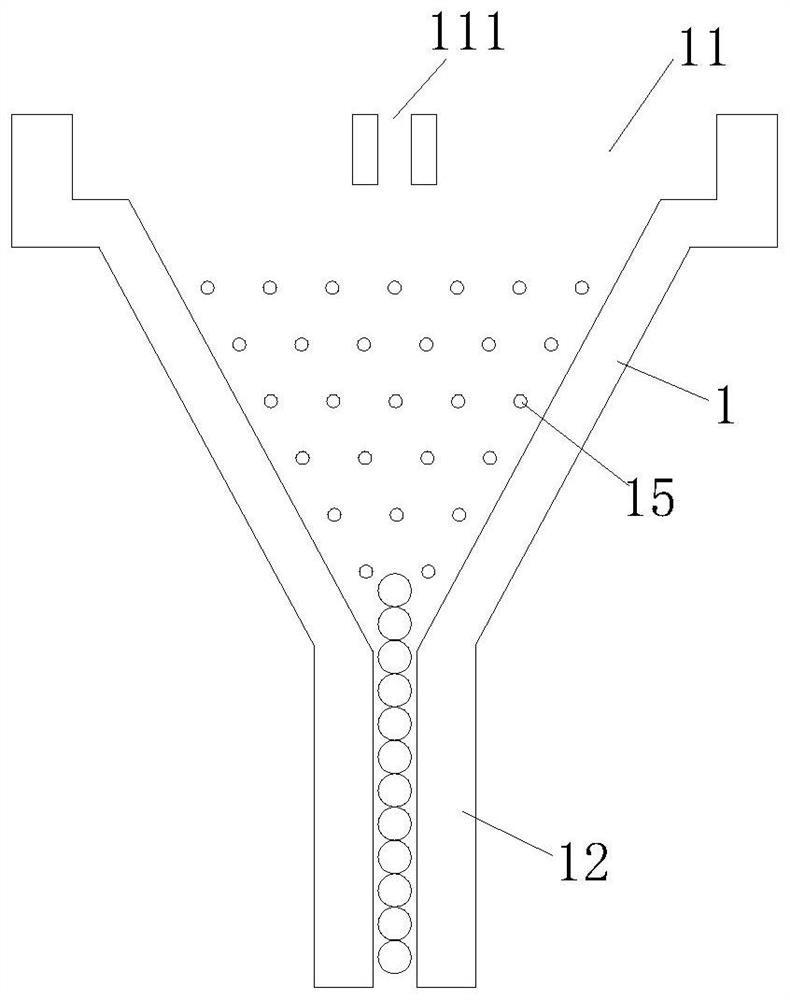

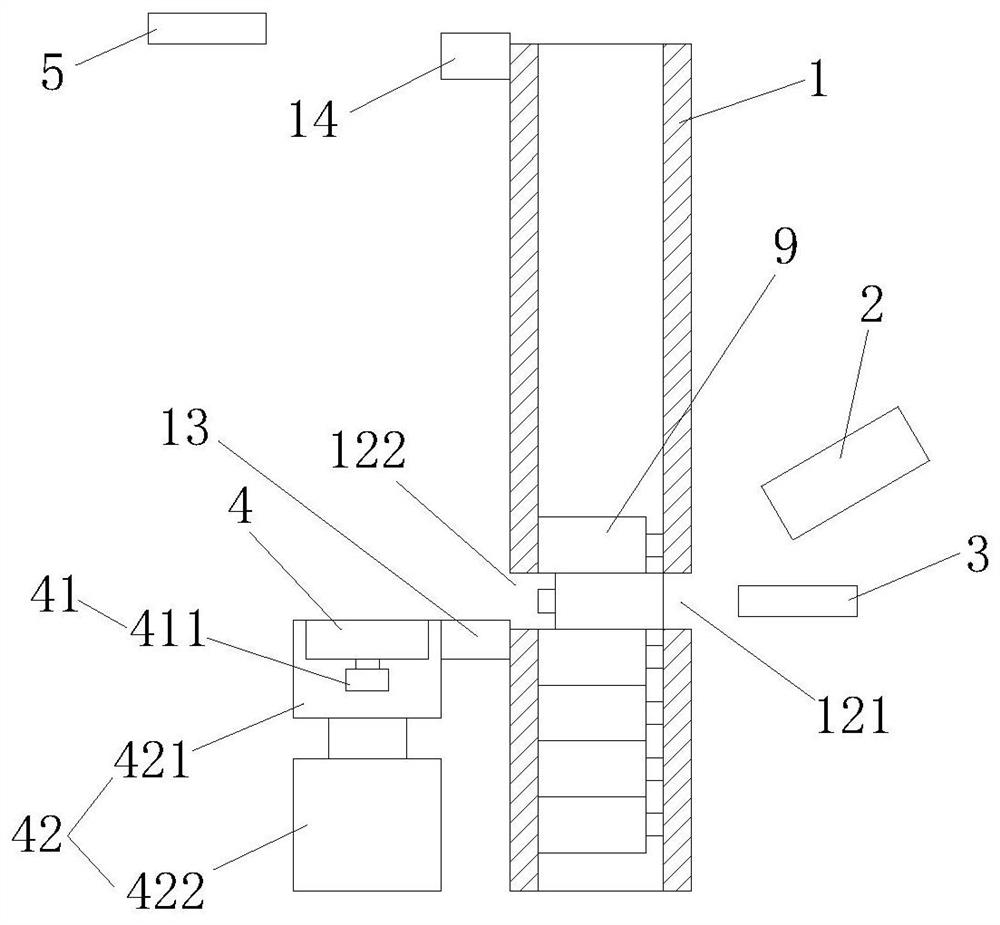

[0020] Embodiment 1, referring to the accompanying drawings, the machine vision-based screening device for lithium battery recycling includes a screening box 1; the upper end of the screening box 1 is provided with a feed port 11; the lower end of the screening box 1 is provided with a discharge channel 12 ;

[0021] The discharge channel 12 is provided with a detection window 121; one side of the detection window 121 is provided with an industrial camera 2; The ejection mechanism 3 of 12; the discharge channel 12 is provided with a discharge port 122 on the side opposite to the ejection mechanism 3 for the lithium battery 9 whose position is unqualified;

[0022] Through the screening of the screening box 1, the lithium battery 9 is in a horizontal state when it is discharged from the screening box 1; the setting of the discharge channel 12 is used to send out the screened lithium battery 9, and of course, the lower end of the discharge channel 12 is provided with Discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com