Disc cutter ratooning rice harvesting header and harvester provided with same

A technology of ratooning rice and harvester, which is applied in the field of harvester, can solve the problems of reducing rolling rate, labor-intensive manual harvesting, power waste, etc., and achieve the effect of meeting growth needs, realizing light weight, and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

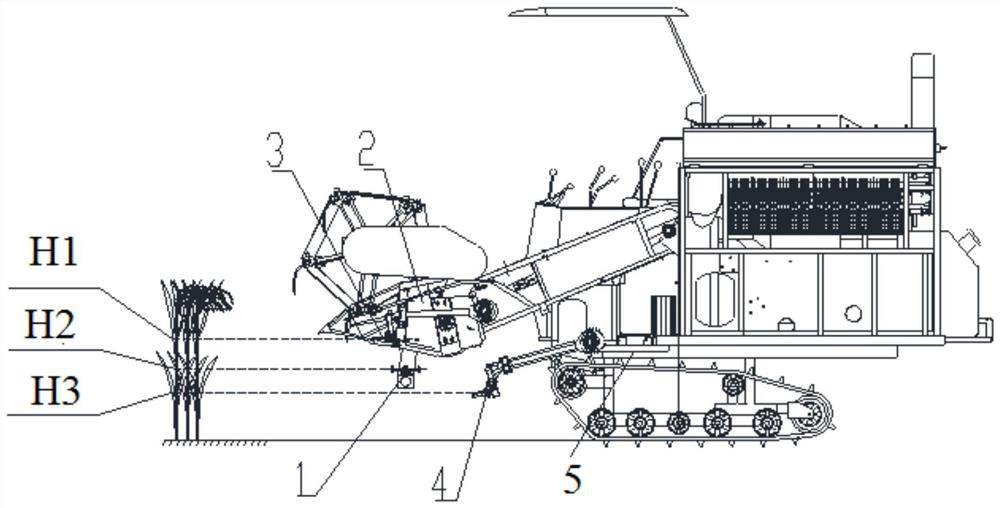

[0024] figure 1 Shown is a preferred embodiment of the regenerated rice harvesting header of the disc cutter, the regenerated rice harvesting header of the disc cutter includes a disc cutter 1, a header frame 2, an ear head cutting 3 and stubble cutter 4. Wherein, the disk cutter 1 is installed below the header frame 2, and is positioned at the bottom of the ear head cutter 3, the ear head cutter 3 is installed at the front end of the header frame 2, and the stubble cutter 4 is used to be hinged in the harvesting area. On the chassis of the machine and behind the disc cutter 1.

[0025] Such as figure 2 As shown, the disc cutter 1 includes several disc cutter assemblies 1-1, flange 1-2, cutter shaft 1-3, cutter bearing seat 1-4, mounting plate 1-5, connecting plate 1-6, cutter bevel gear 1-7, transmission bevel gear 1-8, transmission shaft 1-9, transmission shaft bearing 1-10 and drive device; the disc cutter assembly 1-1 passes through the flange 1- 2 Installed on one en...

Embodiment 2

[0034] A harvester, comprising the disc cutter regenerated rice harvesting header described in Embodiment 1, therefore has the beneficial effects of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com