A fiber optic mems sensor for cable joints

A cable joint and sensor technology, applied in the field of sensors, can solve the problems of poor fixation and large deviation of collected data, and achieve the effect of simple and firm installation and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

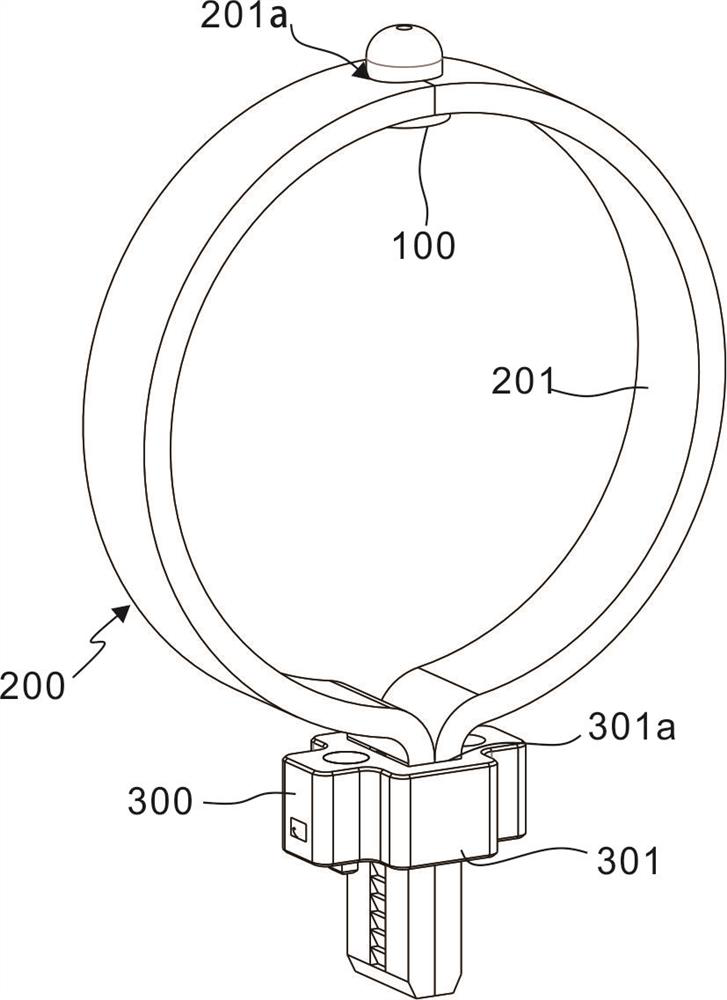

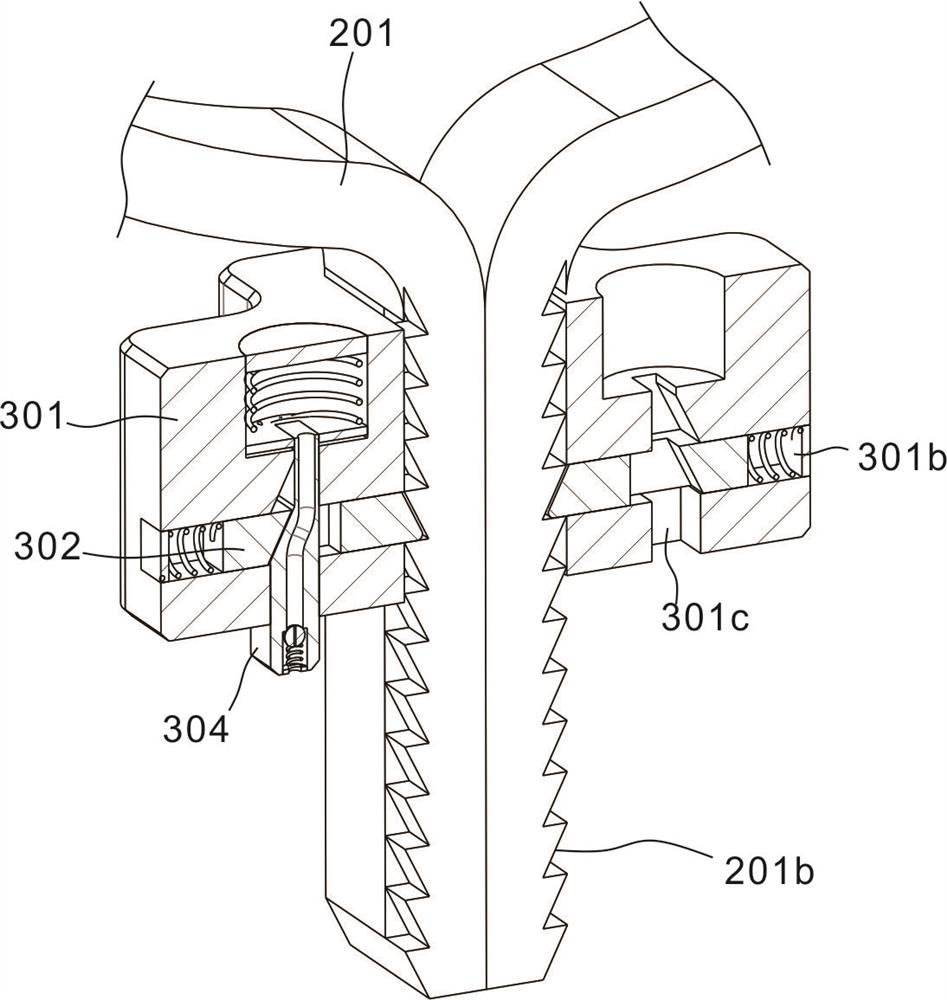

[0031] refer to Figure 1~6 , the present embodiment provides an optical fiber MEMS sensor for a cable joint, including a sensing component 100, a fastening component 200 and a locking component 300, wherein the sensing component 100 is a MEMS sensor, and the fastening component 200 is used for To fix the MEMS sensor on the cable connector, the locking component 300 is used to position the fastening component 200 .

[0032] Specifically, the fastening assembly 200 includes an annular fastening strip 201. The annular fastening strip 201 is ring-shaped and wrapped on the cable joint, wherein a mounting hole 201a is provided in the middle of the annular fastening strip 201, and the sensor assembly 100 is installed on the In the hole 201a, the collection end of the sensing component 100 is in contact with the cable connector for data collection.

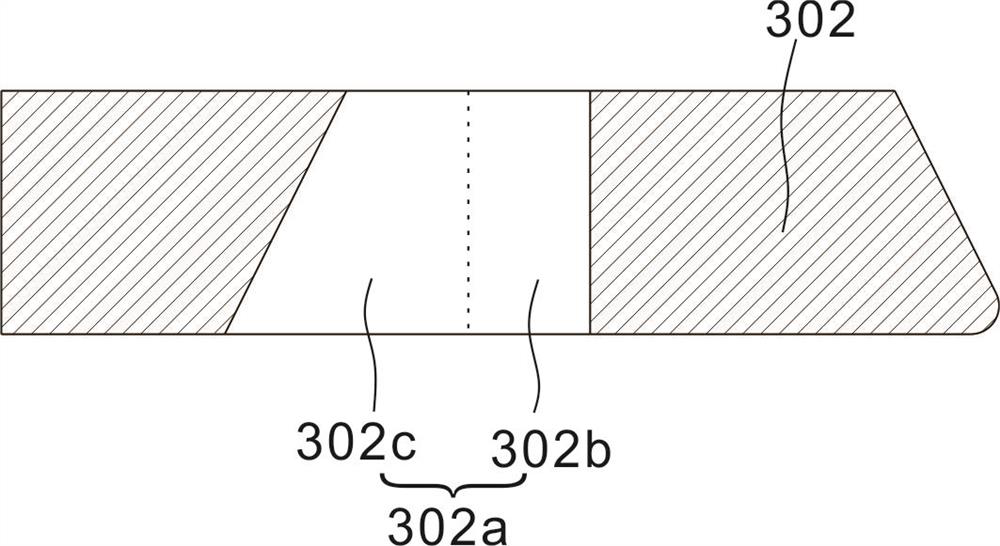

[0033] Further, the locking assembly 300 includes a locking member 301, the locking member 301 is provided with a through hole 301a, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com