Dyeing and finishing process of polyester acetate double-layer georgette fabric

A double-layer, acetic acid technology, applied in the field of fabric dyeing and finishing, can solve the problems of poor dyeing performance, high elongation at break, low color fastness of products, etc., to achieve optimized color and color fastness, good color fastness to washing, Silky and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This application discloses a dyeing and finishing process of acetate-polyester double-layer georgette fabric. The dyed fabric in this application is acetate-polyester double-layer georgette, the specification is 75D+30D / SSY+75D+30D / SSY, and the blank factory is Haiyanjia Source Color Technology Co., Ltd., with a door width of 147cm and a weight of 240g / m 2 .

[0058] The dye used in this example is Charlene Yellow ECF-NEW, the dosage is 1% (owf), and the dyeing and finishing auxiliaries used include JY208L, JY406EA, HAC, JY leveling agent, and phosphorus-free chelating dispersant ZS-558 . The concentration of dyeing and finishing auxiliaries in this implementation is: 1.0g / L of HAC, 1.0g / L of JY208L, 0.4g / L of JY406EA, 0.8 / L of phosphorus-free chelating dispersant ZS-558, 1.0g / L The JY leveling agent.

[0059] A kind of dyeing and finishing process of double-layer georgette fabric of acetate polyester comprises the following steps:

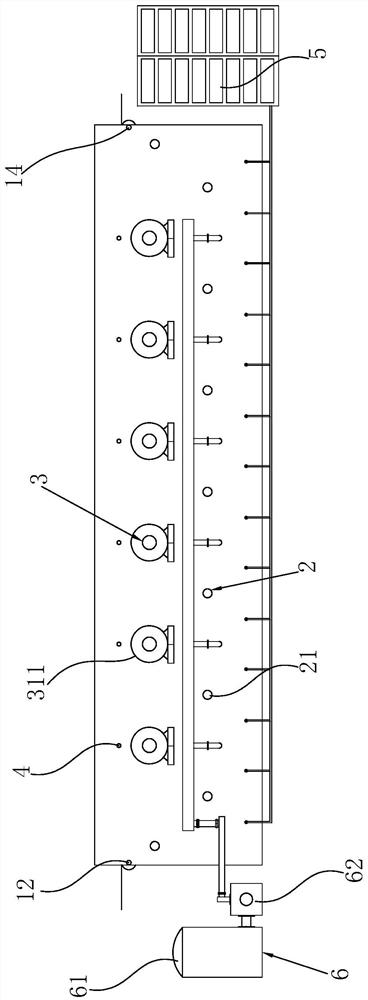

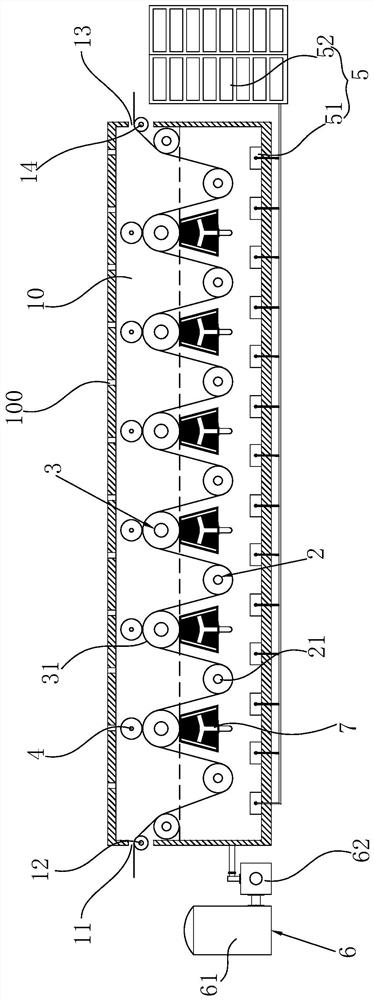

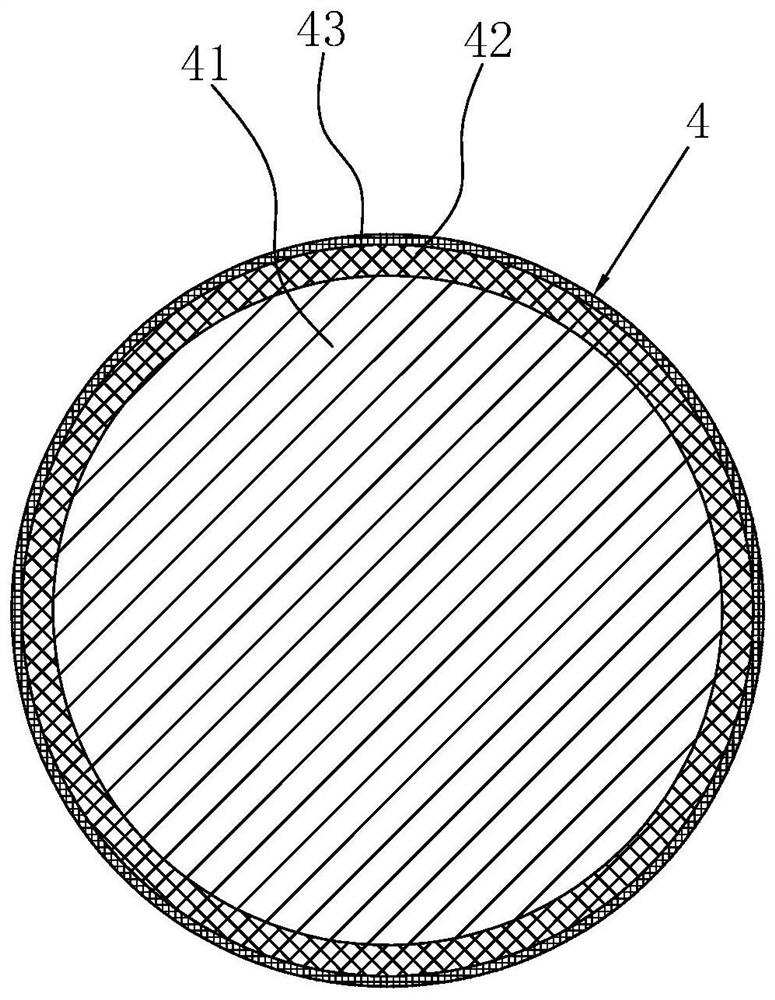

[0060] Step 1, using an unwindin...

Embodiment 2

[0077] The difference between Example 2 and Example 1 is that the dyeing formula 1 in Example 1 is replaced by dyeing formula 2: the target dyeing is red, and the amount of Yingcai clone DRA-2B red used is 0.5%.

Embodiment 3

[0079] The difference between Example 3 and Example 1 is that the dyeing formula 1 in Example 1 is replaced by dyeing formula 3: the target dyeing is blue, and the amount of Yingcai clone DRA-3G blue used is 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com