Ship body and self-propelled three-body wave energy power generation platform

A wave energy, self-propelled technology, applied in the direction of ocean energy power generation, hull, hydrodynamic characteristics/hydrostatic characteristics, etc., can solve the problems of small deck area and cabin volume, high cost, and large influence of floats, etc., to achieve Good stability performance, large deck space, and the effect of increasing the deck area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

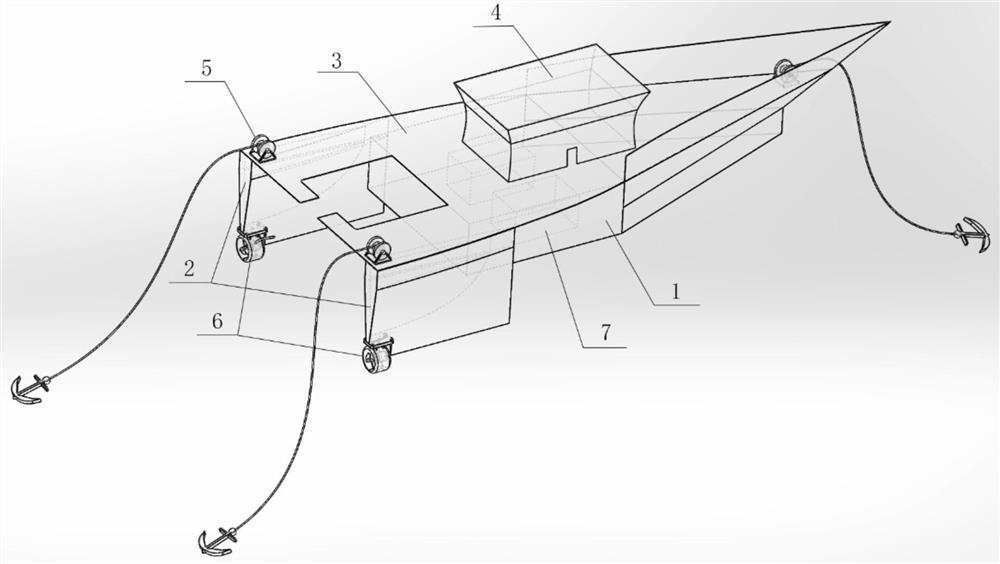

[0039] refer to figure 1As shown, the hull provided by this embodiment mainly includes a main body 1 , two auxiliary bodies 2 , a deck 3 , a superstructure 4 , three sets of mooring systems 5 , and two propellers 6 . Among them, the superstructure 4 is equipped with passenger cabin, cockpit, living facilities, etc., and the deck 3 connects the main body 1 and the auxiliary body 2, that is to say, the three bodies share a main deck and superstructure, which is similar to the monohull. It has the advantages of large deck space and good stability. The main body 1 is a buoyancy chamber, which mainly undertakes the task of wave energy conversion. Its volume is much larger than that of the two sides of the body. It is equipped with equipment 7 such as a power system and an energy storage system. The two auxiliary bodies 2 are small buoyancy chambers. The cabin has the same shape, and a propeller 6 is installed at the bottom, which are arranged in parallel on both sides of the rear ...

Embodiment 2

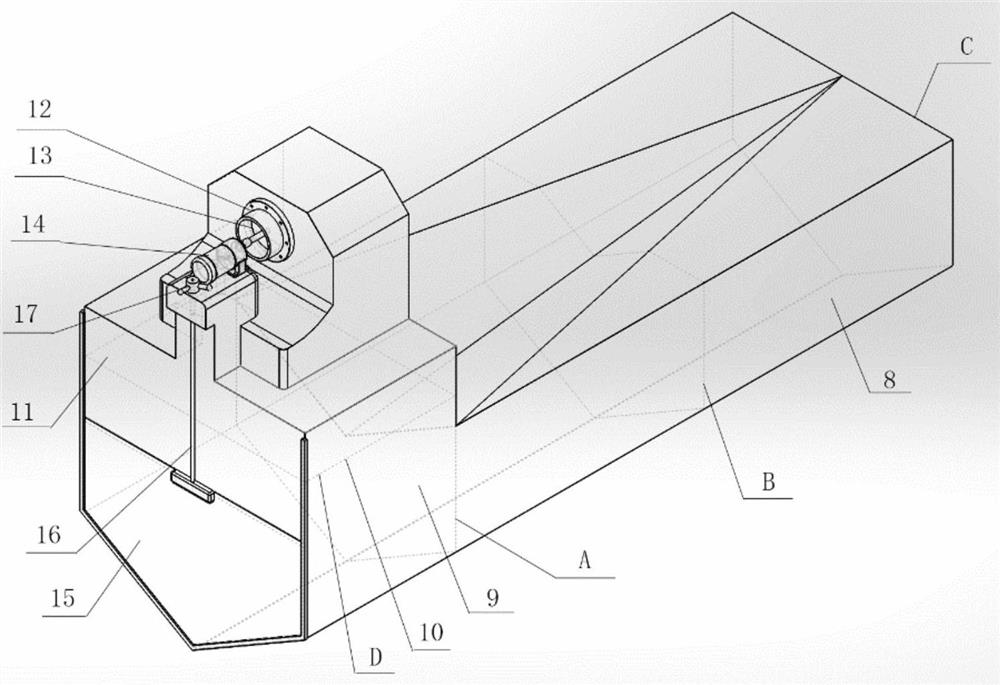

[0043] refer to Figure 2-4 As shown, the self-propelled three-body wave energy generation platform ( Figure 4 ) is mainly composed of the hull described in embodiment 1 ( figure 1 ) and the pneumatic wave energy generating device installed on the hull ( figure 2 ) composed of.

[0044] Such as figure 2 As shown, the pneumatic wave energy generating device includes a horizontal pipe 8 , a vertical cavity 9 , an air turbine 13 and a generator 14 .

[0045] Wherein, the vertical chamber 9 includes an oscillating water column 10, an air chamber 11 and an air hole 12; The upper part is contracted, and an air turbine 13 and a generator 14 are installed on the air inlet and outlet holes 12 .

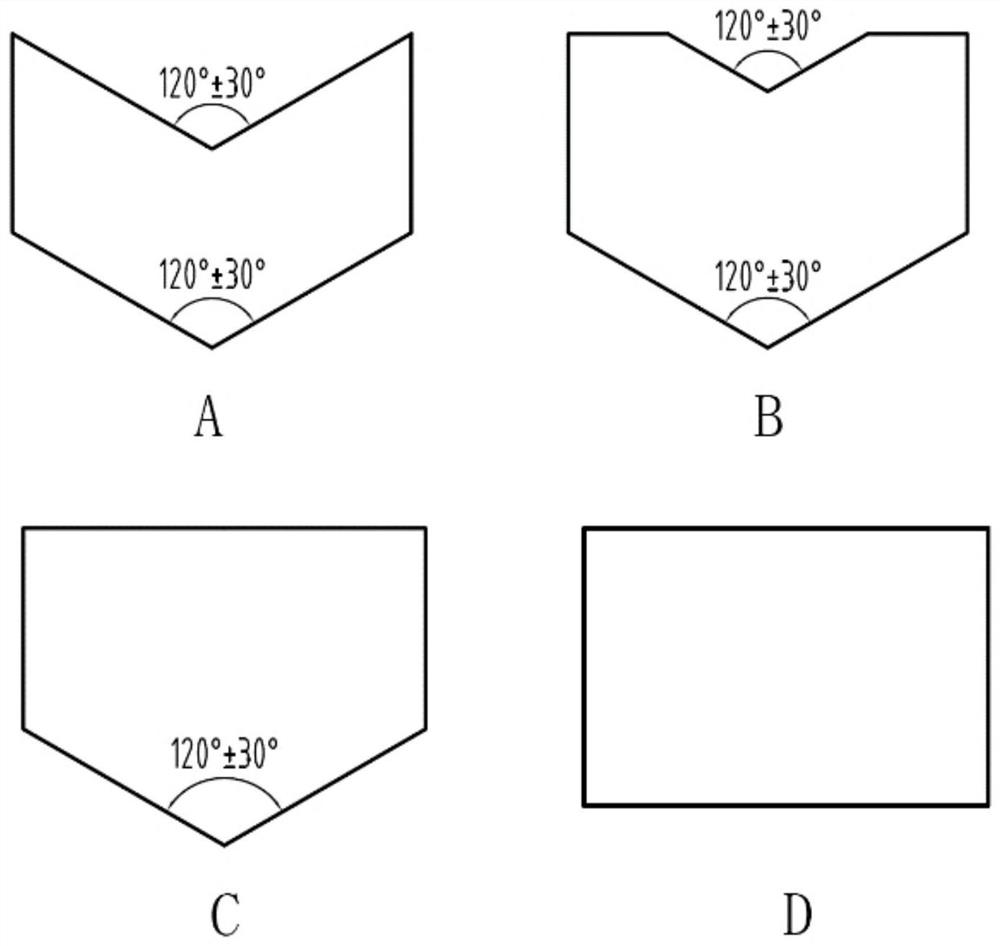

[0046] Such as figure 2 and 3 As shown, the length of the horizontal tube 8 is from figure 2 From the plane where the hexagon A is located to the plane where the pentagon C is located, the vertical section of the horizontal pipe 8 is a "concave" trumpet-shaped mouth, and a pentago...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com