Prefabricated T-beam prefabricated universal beam manufacturing pedestal and construction method

A technology for making beam pedestals and universal systems, which is applied in the direction of manufacturing tools, unloading devices, mold fixing devices, etc., can solve the problems of prefabricated pedestals not being used concurrently, achieve high construction efficiency, strong mobility, and improve site utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

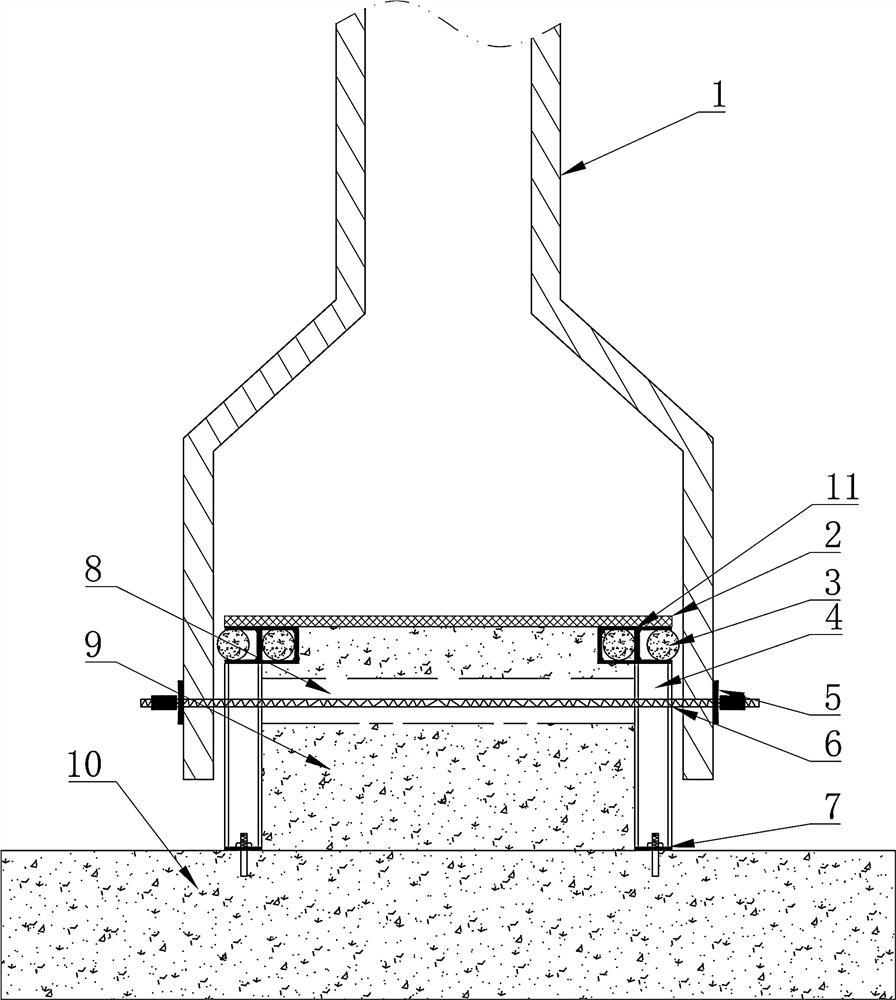

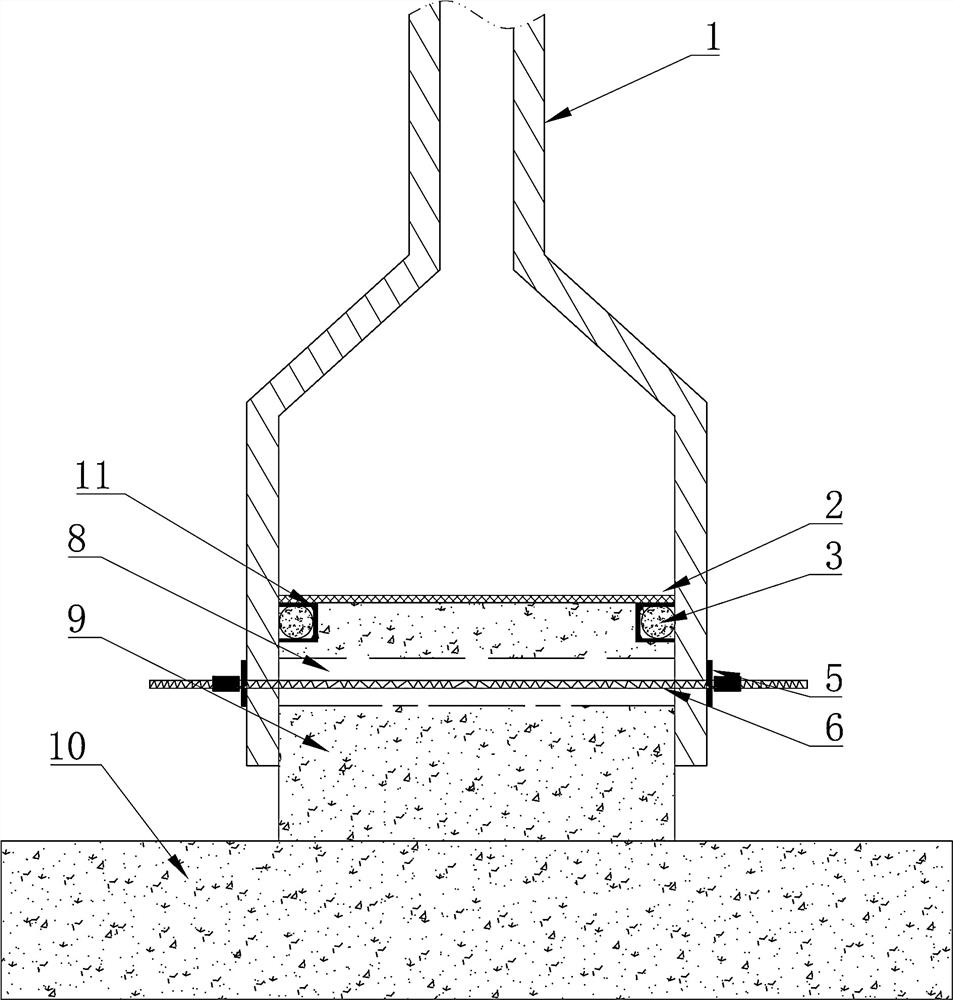

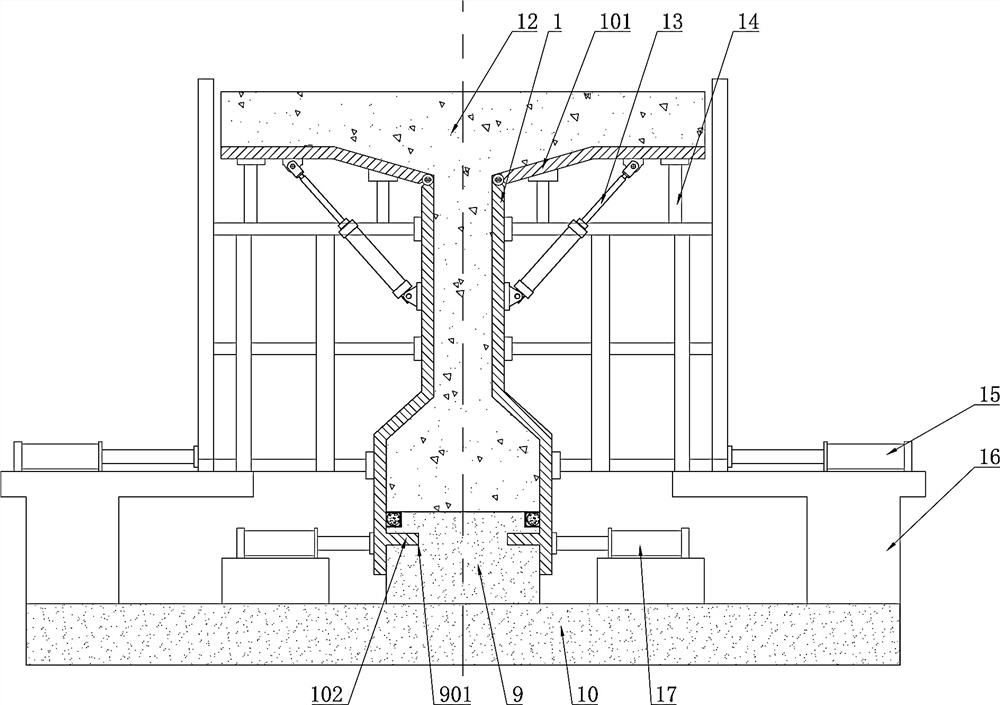

[0037] Such as Figure 1-6 As shown, an assembled T-beam prefabricated universal beam-making pedestal, beam formwork 1 is provided on both sides of the beam-making pedestal 9, the beam formwork 1 is slidingly connected with the beam-making pedestal 9, and the beam formwork 1 is connected to the beam-making pedestal 9 through a locking structure. connection, the beam-making platform 9 is also provided with at least one slurry-stopping groove 11, the inside of the slurry-stopping groove 11 is provided with a slurry-stopping bar 3, and the inner wall of the beam template 1 is against the slurry-stopping bar 3. Both sides of the beam-making pedestal 9 are provided with channel steel columns 4, at least one slurry-stopping groove 11 is arranged on the channel steel column 4, the inner wall of the beam template 1 is against the channel steel column 4, and the lower end of the channel steel column 4 is set by an expansion bolt 7. on the foundation pad 10. The locking structure inclu...

Embodiment 2

[0048] Further illustrate in conjunction with embodiment 1, Figure 1-6 As shown, on both sides of the beam-making base 9, first install the slurry-stop groove 11, install the slurry-stop rod 3 inside the slurry-stop groove 11, and then install the beam formwork 1, and the pull screw 6 passes through the beam formwork 1 and the through groove 8 on both sides to lock Tightly on the beam making pedestal 9, place the steel panel 2 at the bottom of the beam at the beam making pedestal 9.

[0049] Adjust the width of the beam formwork 1, place the channel steel column 4 on both sides of the beam making platform 9, the bottom is locked on the foundation cushion 10 by the expansion bolt 7, and then install the second grouting tank 11 on the channel steel column 4 to stop the grouting The slurry rod 3 is installed inside the groove 11, and then the beam formwork 1 and the through groove 8 on both sides are passed through the beam formwork 1 and the through groove 8 on both sides by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com