Auxiliary device for preheating and heat preservation of weld joint of pressure steel pipe and construction method

A pressure steel pipe and auxiliary device technology, which is applied in the field of auxiliary equipment for the preheating and heat preservation of the pressure steel pipe weld, can solve the problems of unstable fixing of the heating plate, hidden dangers in construction, etc., achieves strong operability and practicability, and reduces the production cost. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

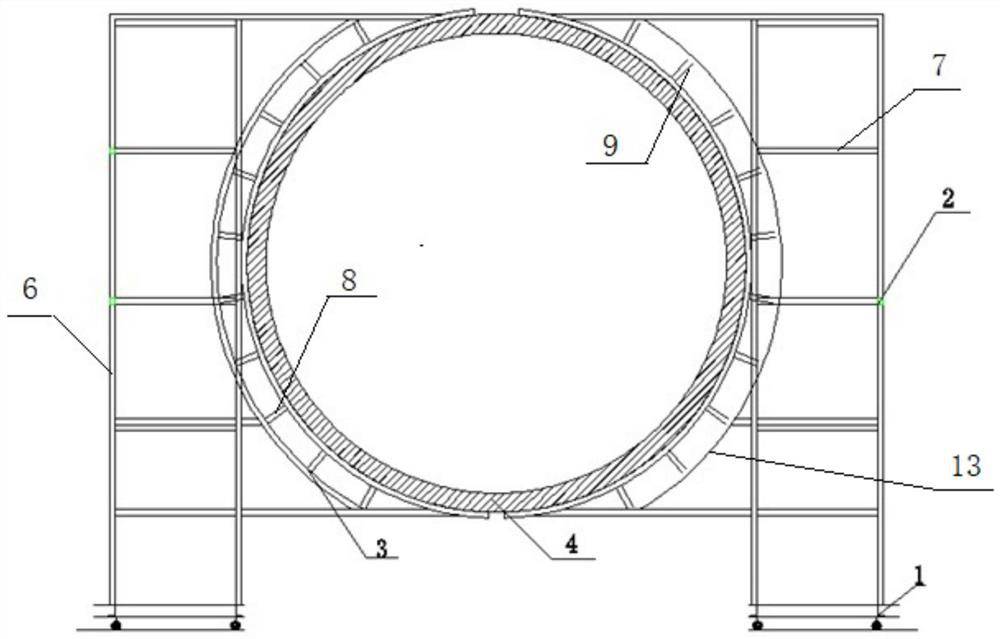

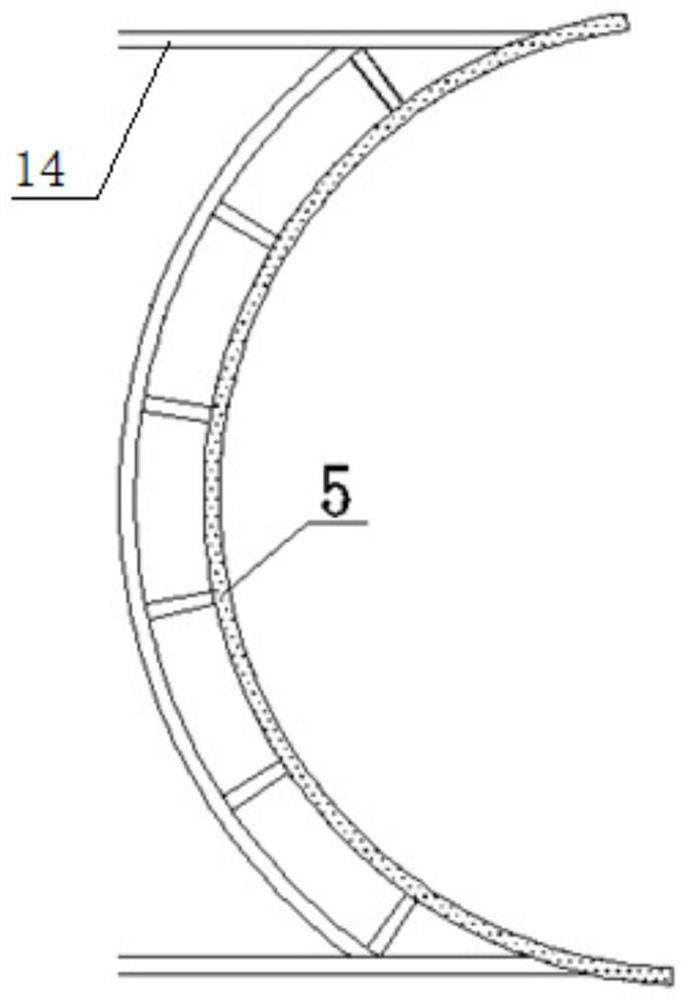

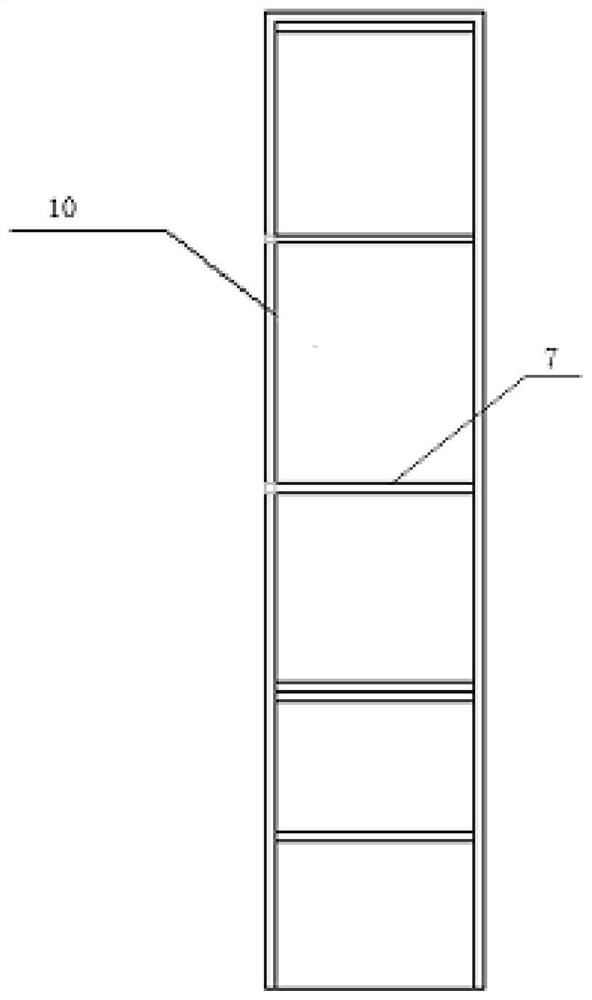

[0040] Such as figure 1 As shown, the present invention provides an auxiliary device for preheating and heat preservation of penstock welds, including a base 1, universal wheels, columns, brackets, and fixing devices. The universal wheel wing plate is welded to the base 1, and the base 1 is provided with a fixing device for fixing the position of the bracket. The fixing device can be moved and fixed in the vertical direction on the base 1. The upper part of the base 1 is equipped with a column, and the column and the The base 1 is welded and connected, and the side of the column is welded and connected to the bracket holding the heating plate, and the bracket is welded to the column.

[0041]Specifically, in order to ensure the overall stability of the present invention and the principle of lowering the center of gravity, the base 1 selects he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com