Pressure-adjustable magnetic core bonding tool

An adjustable, magnetic core technology, used in workpiece clamping devices, connecting components, manufacturing tools, etc., can solve the problems of poor consistency of output parameters, low work efficiency, low product qualification rate, etc., to improve production efficiency and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

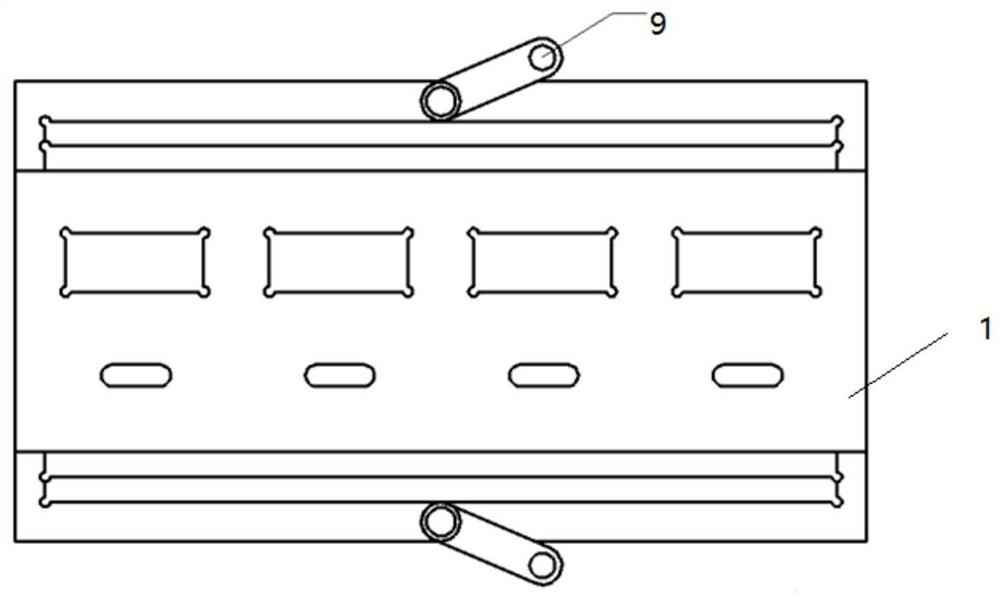

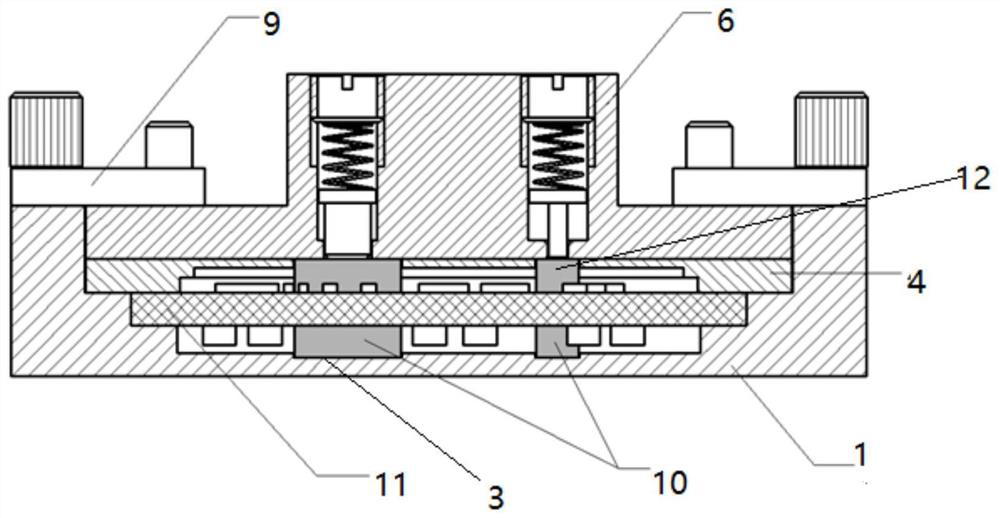

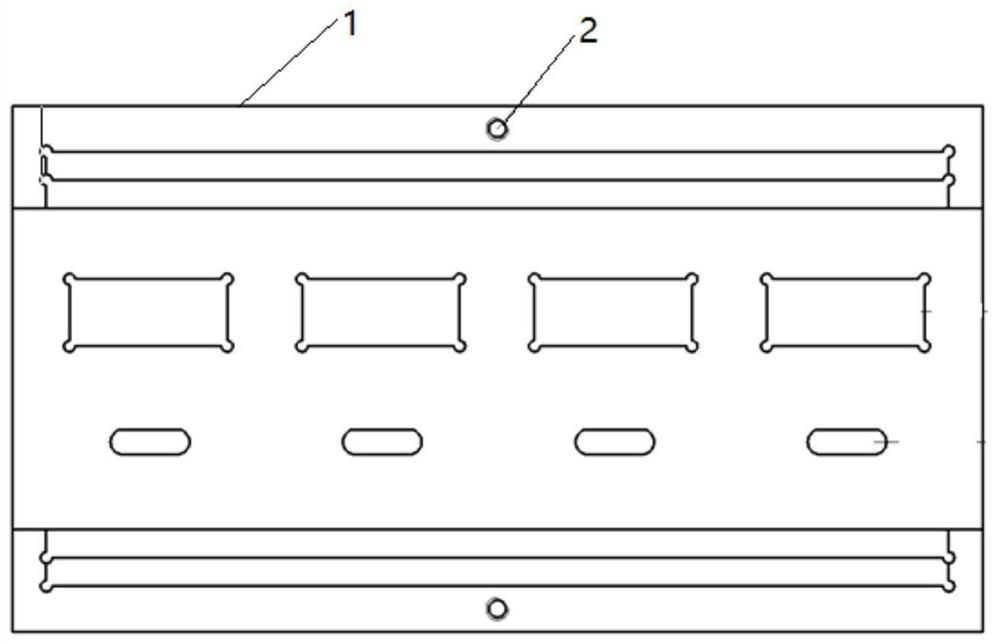

[0028] like figure 1 As shown, the present embodiment provides a pressure-adjustable magnetic core bonding tool, including a base 1, and the base 1 is sequentially provided with a lower magnetic core slot 3 for placing the lower magnetic core 10 from bottom to top, and the lower magnetic core slot 3 There are multiple quantities, depending on the needs of the actual situation, the circuit board slot for placing the circuit board 11, the upper magnetic core slot for placing the upper magnetic core board 4, and the number of the upper magnetic core slots. Depending on the situation, the upper core plate 4 is provided with a positioning window 5 that is convenient to put into the upper magnetic core 12. The number of positioning windows 5 is not limited. The upper magnetic core 12 and the lower magnetic core 10 The alignment is fixed on the upper and lower surfaces of the circuit board 11 by dispensing glue on the bonding surface of the magnetic core by an automatic glue dispense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com