Temperature drift calibration method for high-precision low-temperature drift temperature measurement circuit of infrared detector

A technology of infrared detector and calibration method, which is applied in the field of aerospace optical remote sensors, can solve problems such as temperature drift compensation effect verification, and achieve the effect of simple algorithm, avoiding high cost, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

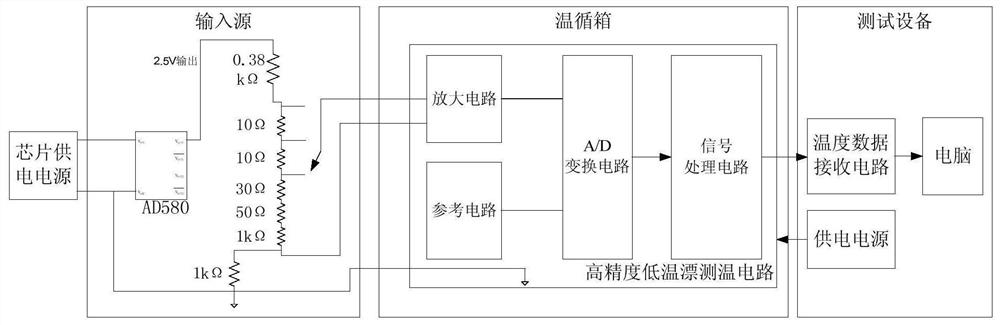

[0040] The temperature drift calibration system includes: signal analog input source, high-precision temperature measurement control circuit, temperature cycle box, test equipment and connecting cables. The high-precision temperature measurement control circuit includes: amplifying circuit, reference circuit, A / D acquisition unit and data receiving and processing unit. Signal analog input sources include: chip power supply, voltage source reference chip, precision resistors;

[0041] 1) Connect the signal analog input source, high-precision temperature measurement control circuit, and test equipment in sequence through the connecting cable figure 1 connection; the high-precision temperature measurement control circuit is placed inside the temperature cycle box; the temperature cycle box is used to adjust the temperature of the high-precision temperature measurement control circuit. The high-precision temperature measurement control circuit includes: an amplification circuit a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com