A New Type of Cooling Structure of Multi-inclined Orifice Plate Ellipsoid Pendulum for Aerospace Engine

A technology of aerospace engine and cooling structure, which is applied in the cooling of engines, engine components, cooling of turbine/propulsion devices, etc., can solve the problems of difficulty in controlling the amount of cold air intake, reducing cooling performance, and intensifying the mixing of cold air and hot air, etc. Achieve the effect of increasing the coverage area of cold air, increasing the degree of stability, and strengthening the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

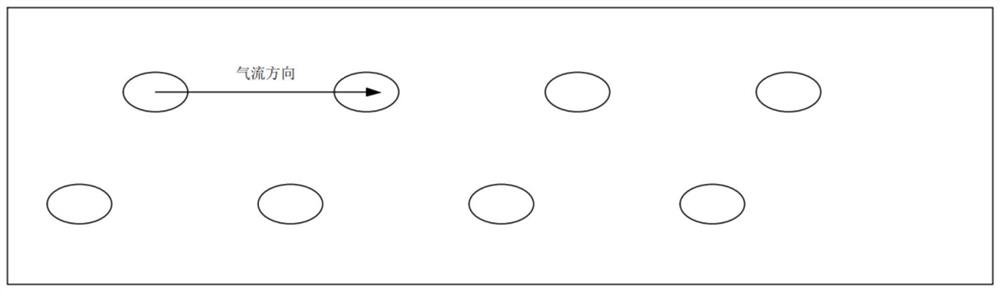

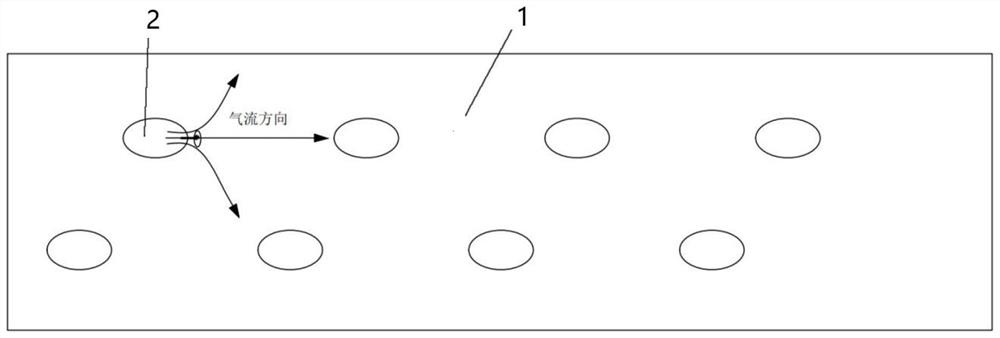

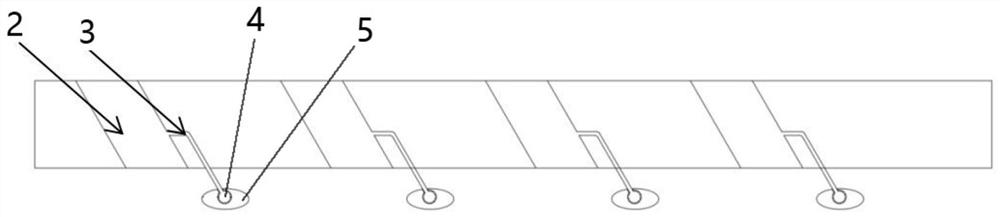

[0024] A new type of multi-slope hole plate ellipsoidal pendulum cooling structure for aerospace engines in this embodiment includes cooling slant holes 2 uniformly arranged on the wall 1 of the combustion chamber flame tube, and the cooling gas can enter the combustion chamber flame through the cooling slant holes 2 In the cylinder and on the inner wall of the combustion chamber flame cylinder, a gas film is formed, and the high-temperature gas and cooling gas flow from front to rear in the combustion chamber flame cylinder, wherein: the cooling inclined hole 2 is connected with the bleed air channel 3, and the bleed air channel 3 extends to The inside of the combustion chamber flame tube is connected with a spherical axis 4. The ellipsoid 5 is located between the front and rear adjacent cooling oblique holes 2 inside the combustion chamber fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com