Open end rotor spinning device

A rotor spinning, free-end technology, which is applied to open-end spinning machines, spinning machines, and continuously wound spinning machines, etc., can solve the problems of complex structural design, difficult manipulation, and large structural space, and achieve improved textiles. Physical values, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

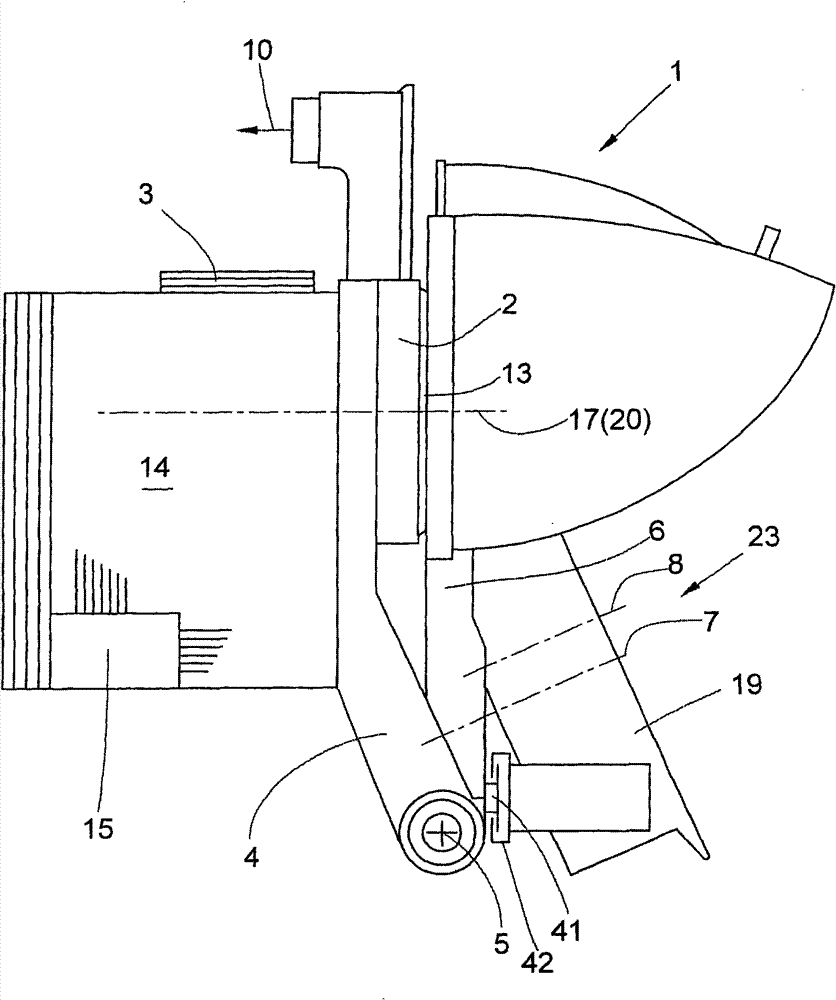

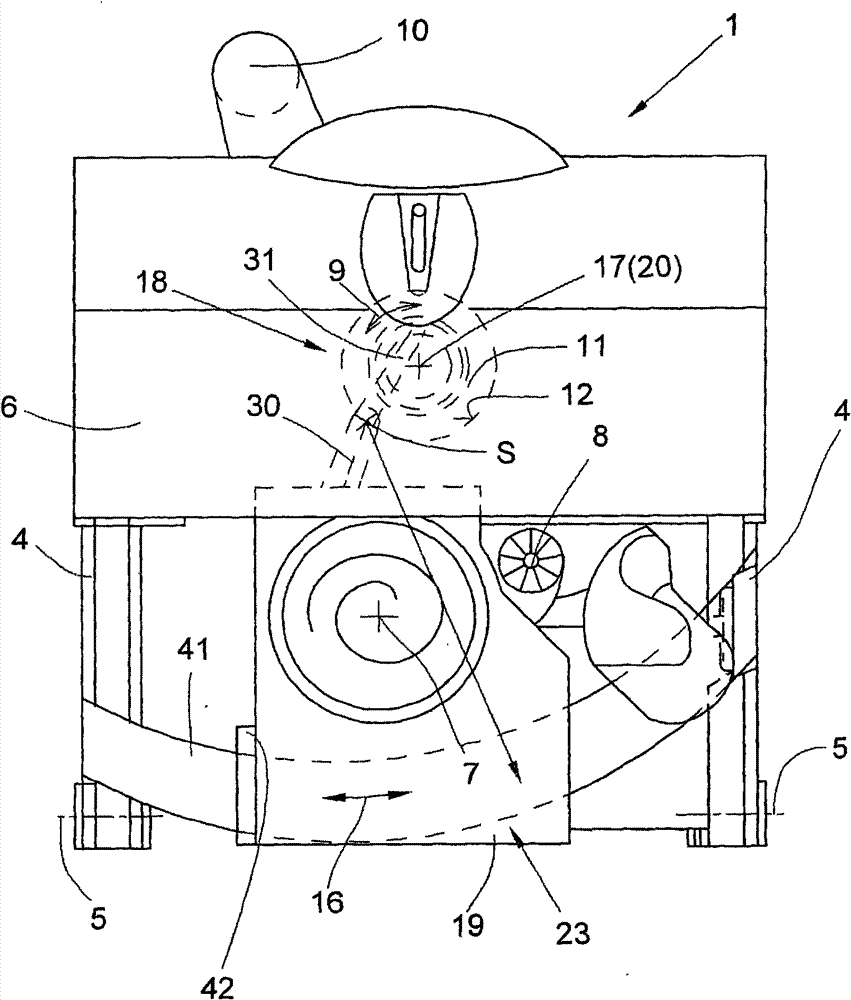

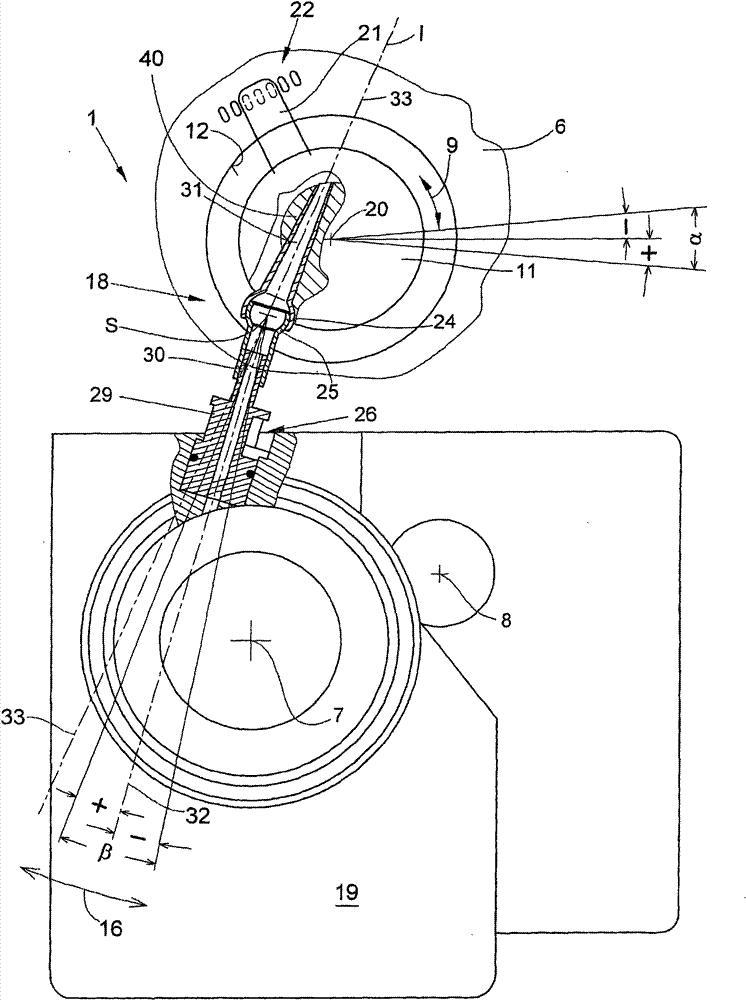

[0040] figure 1 An open-end rotor spinning device 1 is shown, the individual rotatably mounted functional elements of which can each be driven by a separate motor. An open-end rotor spinning device 1 of the type described, for example, in DE 103 40 657 A1 generally has a separate drive for the spinning rotor, a separate drive for the opening rollers and a separate drive for the sliver feed drum.

[0041] exist figure 1 The central spinning rotor, the opening rollers and the sliver feed cylinder are only shown schematically with their axes of rotation 17 , 7 and 8 , respectively. The spinning rotor, supported in magnetic bearings (not shown) and electromagnetically driven by a separate drive 3, rotates at high rotational speeds within the rotor housing 2, which can be subjected to negative pressure, during the spinning operation.

[0042] The rotor housing 2 is usually connected via a pneumatic line 10 to a source of negative pressure (not shown), away from the separate drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com