Gypsum-based building material product moisture-proof treatment process using industrial waste acid

A technology for industrial waste acid and moisture-proof treatment, applied in the field of building materials, can solve the problems of limited use scenarios and short water resistance of gypsum-based building materials products, and achieve the effects of outstanding economic benefits, improved strength, and strong technical versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Using the moisture-proof treatment process described in the present invention to process the phospho-building gypsum block specifically includes the following steps:

[0045] (1) Primary crystallization treatment: Soak the phospho-building gypsum block in the phosphoric acid-containing wastewater discharged from the industrial wet method of preparing phosphoric acid for 3 hours;

[0046] (2) One-time alkali treatment: soak the phospho-building gypsum block after the first crystallization treatment in saturated lime water for 2 hours;

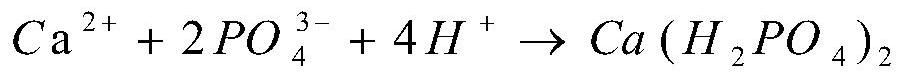

[0047] (3) Secondary crystallization: Soak the phosphorus building gypsum block in the industrial wastewater containing phosphoric acid again to generate calcium monohydrogen phosphate and calcium dihydrogen phosphate crystals;

[0048] (4) Secondary alkali treatment: the phosphogypsum building blocks after the secondary crystallization treatment are soaked in saturated lime water to convert calcium monohydrogen phosphate and calcium dihy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com