Flexible air pipe winding and unwinding device for air supply

A retractable device and air duct technology, which is applied in the field of flexible air duct retractable devices for air supply, can solve the problems of short service life of gas transmission pipeline, increase gas transmission resistance, affect the flow area of air duct, etc., and achieve easy installation. The effect of implementing, small air supply resistance, improving safety performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] In industrial production sites, there are many sites that require forced air supply. The locations or facilities that require air supply are always in a state of motion. A kind of air supply volume that can reach 2,000 to 10,000 cubic meters per hour is required, and can be used for a long time. Air supply for continuous operation.

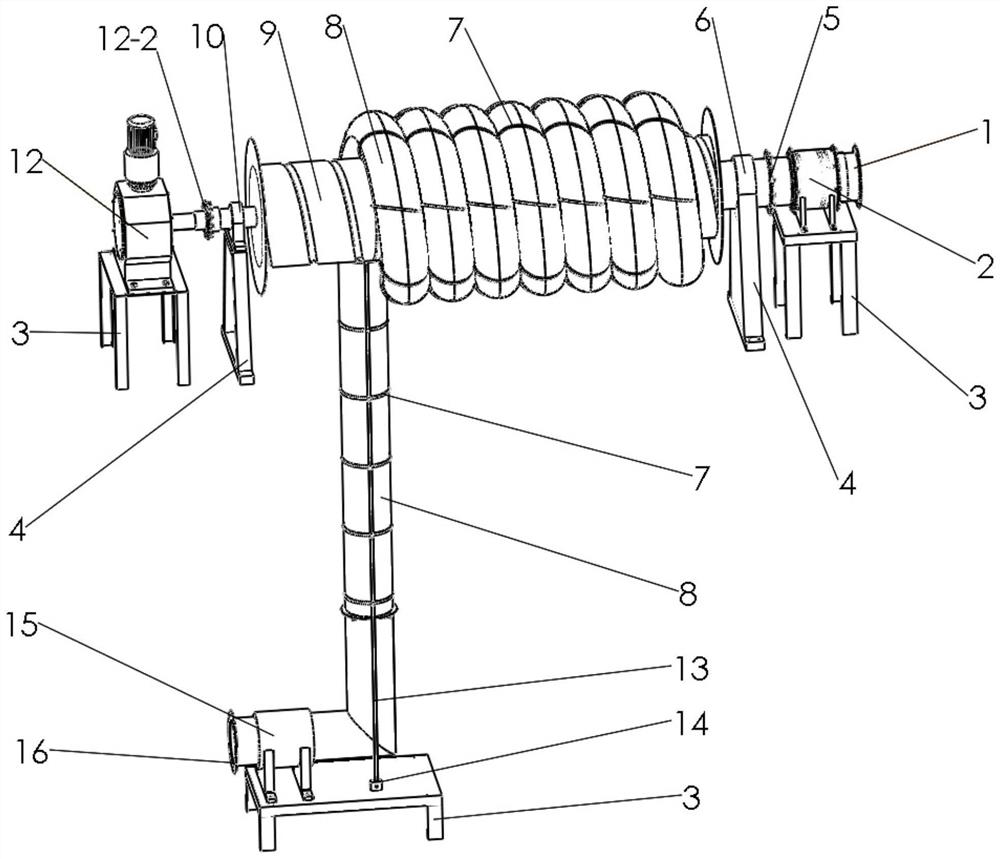

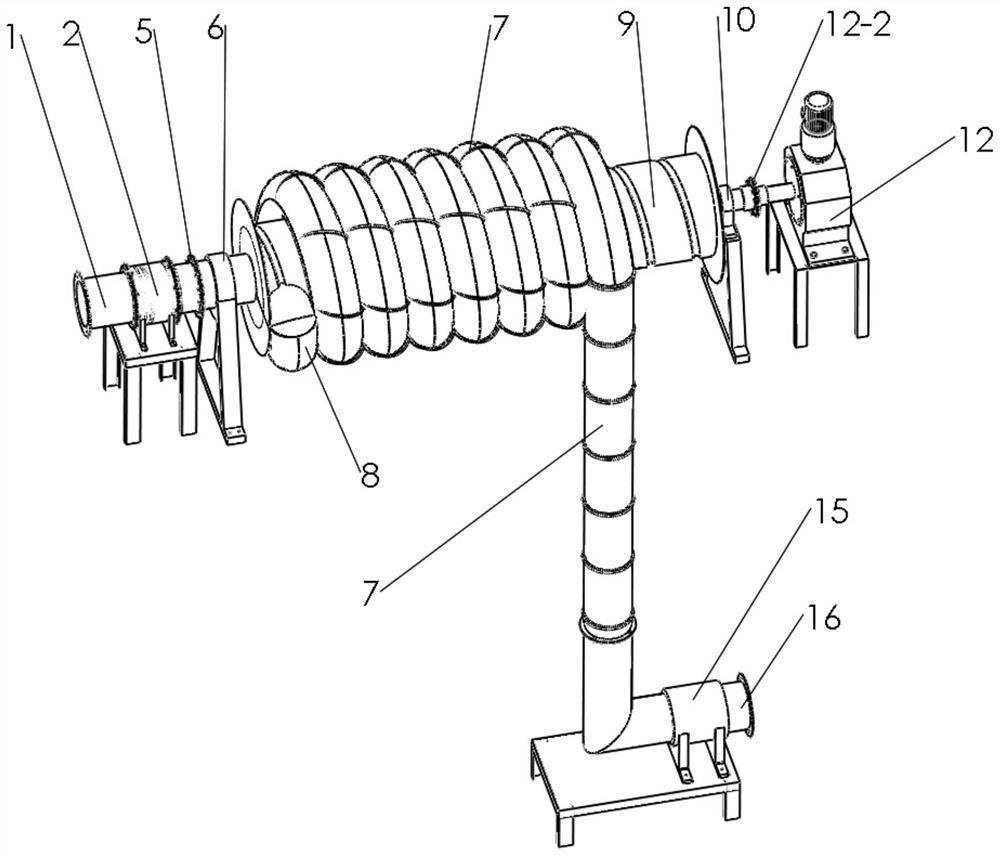

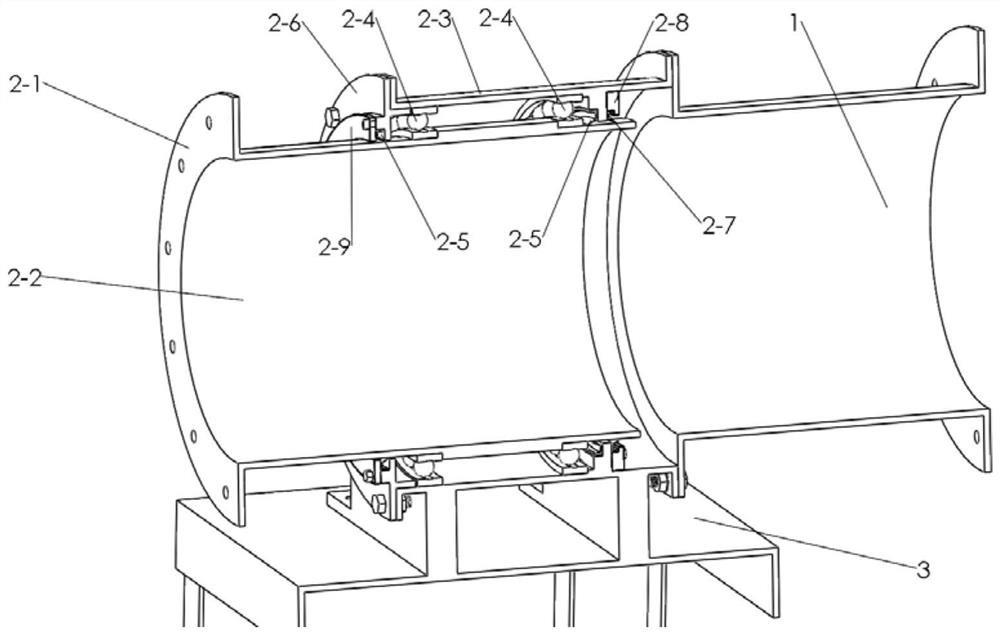

[0037] This embodiment provides a flexible air duct retractable device for air supply, such as Figure 1-8 As shown, it includes an air duct reel assembly, a flexible air duct 8, two reel seats, a rotating air intake assembly 2 and a rotary drive assembly 12 for driving the air duct reel assembly to rotate.

[0038] When it is in use, it cooperates with the air supply fan to send air into the air inlet of the rotary air inlet assembly 2, and then into the flexible air duct 8 through the air duct reel assembly, and the air outlet of the flexible air duct 8 is located at the place or facility office.

[0039] Specifically, in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com