Intelligent multi-station material transferring mechanical arm for plastic product production and method thereof

A technology of plastic products and manipulators, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of plastic size and shape adjustment of the material transfer manipulator, loose contact between the material transfer manipulator and plastic, damage to the material transfer manipulator, etc., to achieve convenience Reset, avoid loosening, and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

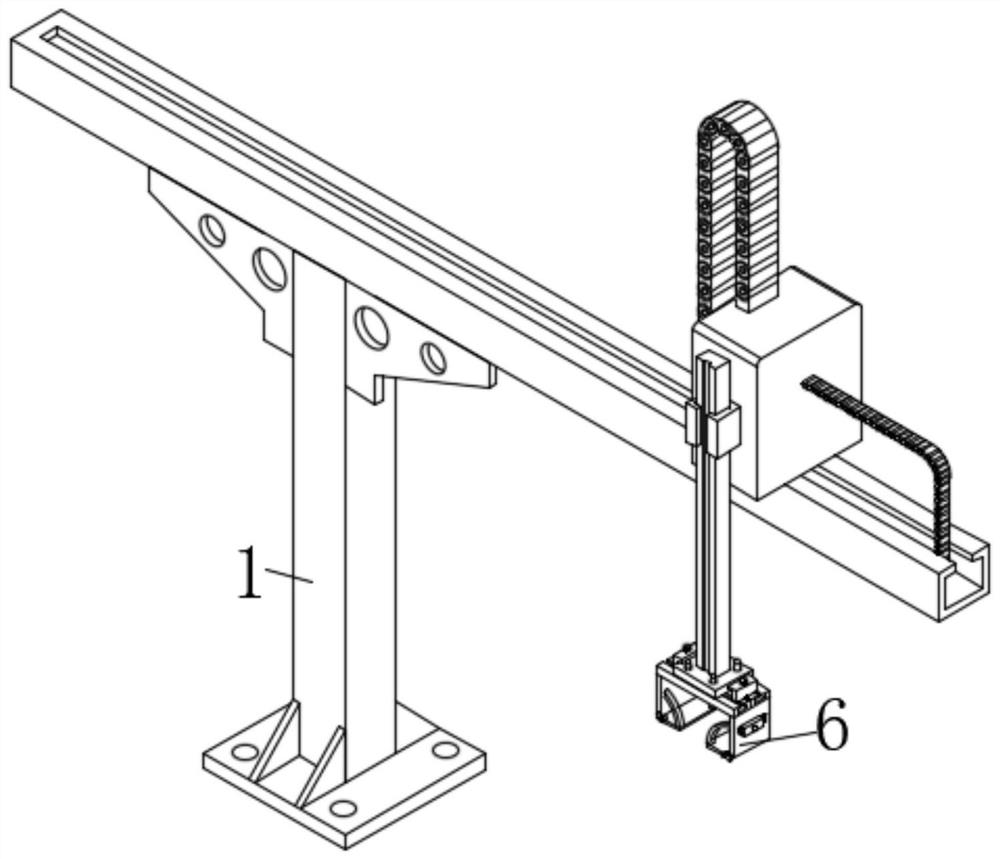

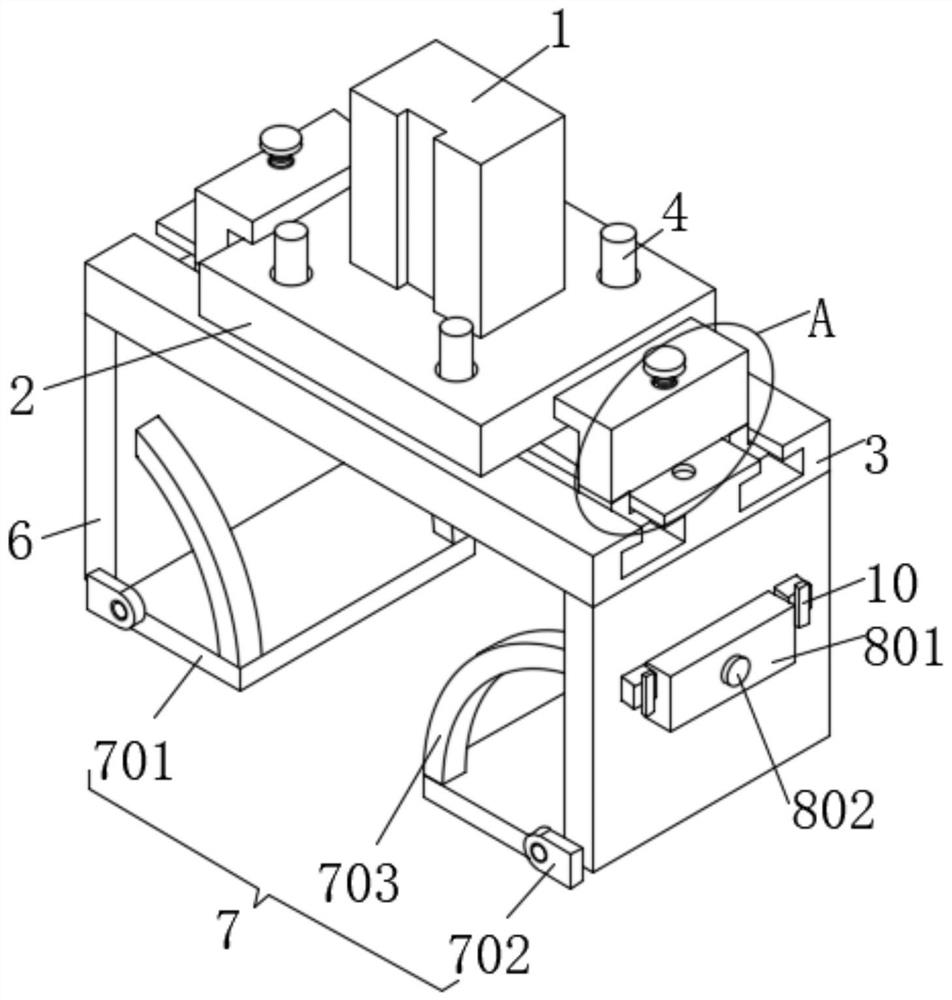

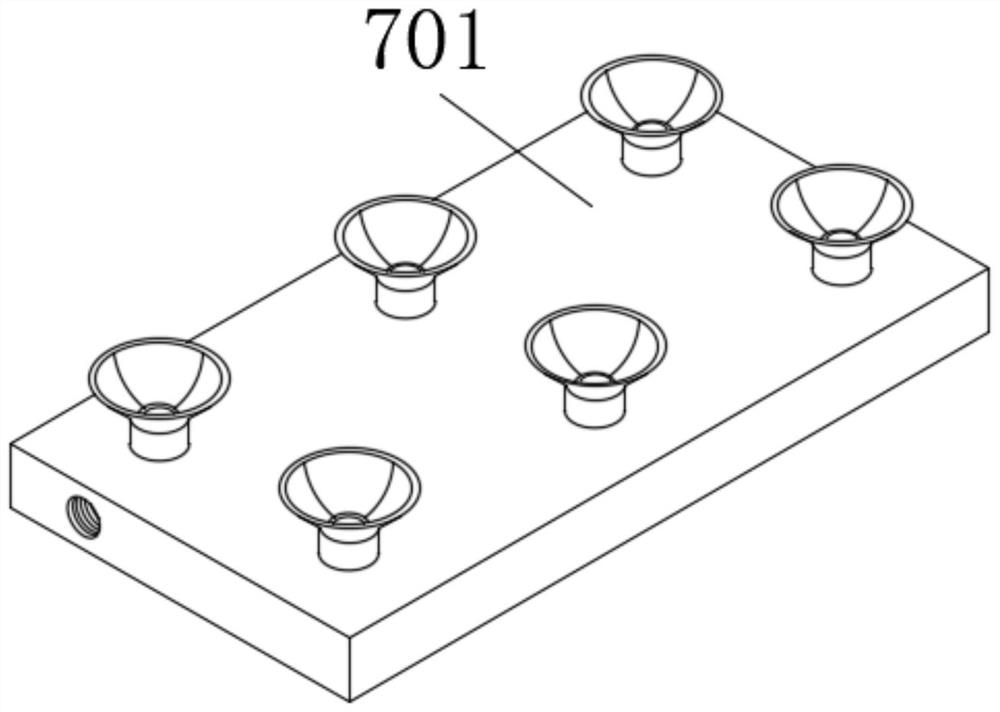

[0034] refer to Figure 1-8 , an intelligent multi-station material transfer manipulator for the production of plastic products, comprising a material transfer manipulator 1, the output end of the material transfer manipulator 1 is fixedly connected with a first fixed plate 2, and the bottom of the first fixed plate 2 is provided with a second Fixed plate 3, the top of the second fixed plate 3 is fixedly connected with fixed column 4 around the top, the top of the fixed column 4 runs through the first fixed plate 2 and extends to the top of the first fixed plate 2, the two inside of the second fixed plate 3 Both sides are movably connected with a clamping mechanism 5, and the inside of the clamping mechanism 5 is used in cooperation with the surface of the first fixed plate 2, and both sides of the bottom of the second fixed plate 3 are fixedly connected with a third fixed plate 6, and the third fixed plate The inside of 6 is movably connected with a rotating mechanism 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com