Belt conveyor mobile tail device with crawler

A belt conveyor and moving machine technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of low efficiency, large use limitations, and can only move in a straight line, so as to achieve convenient use and solve the problem of moving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

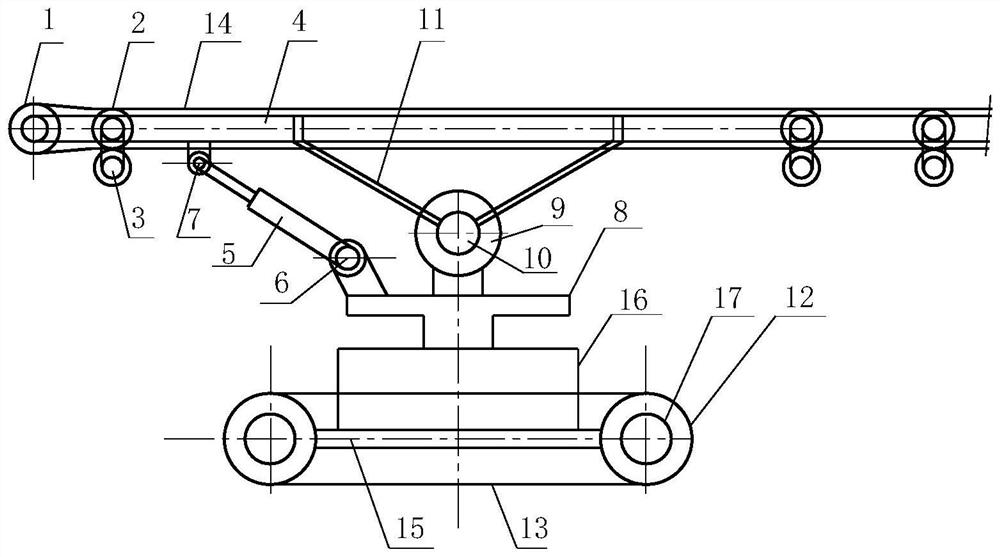

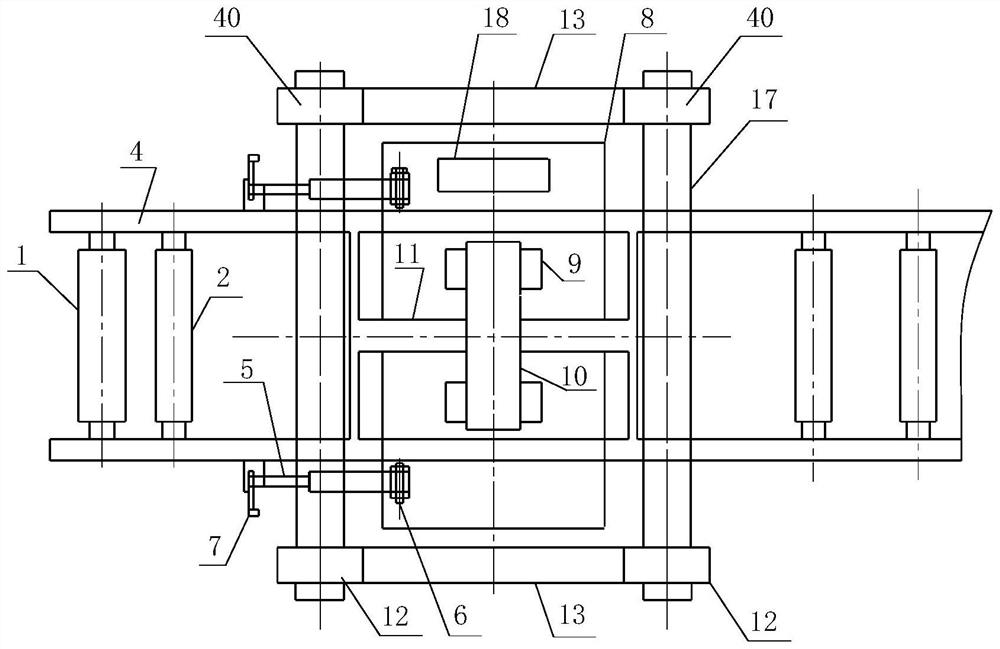

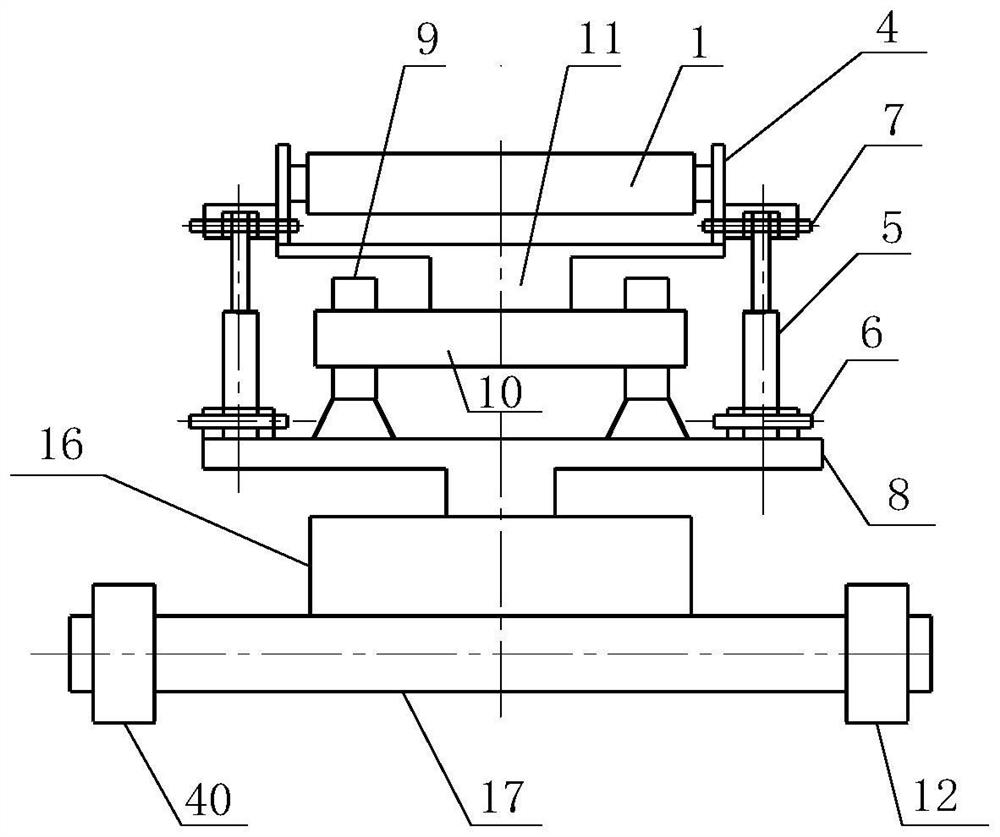

[0016] like Figure 1 to Figure 3 As shown, the moving tail device of the belt conveyor with the crawler of the present application is mounted on the tail of the belt conveyor. The belt conveyor includes: a tail drum 1, a number of upper idlers 2, a number of lower idlers 3, a belt frame 4 and a belt 14. The belt frame 4 is two parallel steel frames, and the tail drum 1 is installed at both ends. At one end between the above two parallel steel frames, the two ends of several upper rollers 2 are installed between the two parallel steel frames, the two ends of several lower rollers 3 are connected to both ends of the upper roller 2, and the belt 14 Around the tail drum 1, the upper idler roller 2 supports the upper edge of the belt 14, and the lower idler roller 3 supports the lower edge of the belt 14.

[0017] like Figure 1 to Figure 3 As shown, the mobile tail device includes: a jack 5, a supporting upper bearing 8, a rotating shaft seat 9, a rotating shaft 10, a support f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap