Gearbox drive unit

A technology of drive unit and transmission device, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as redesign, and achieve the effect of simplified manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

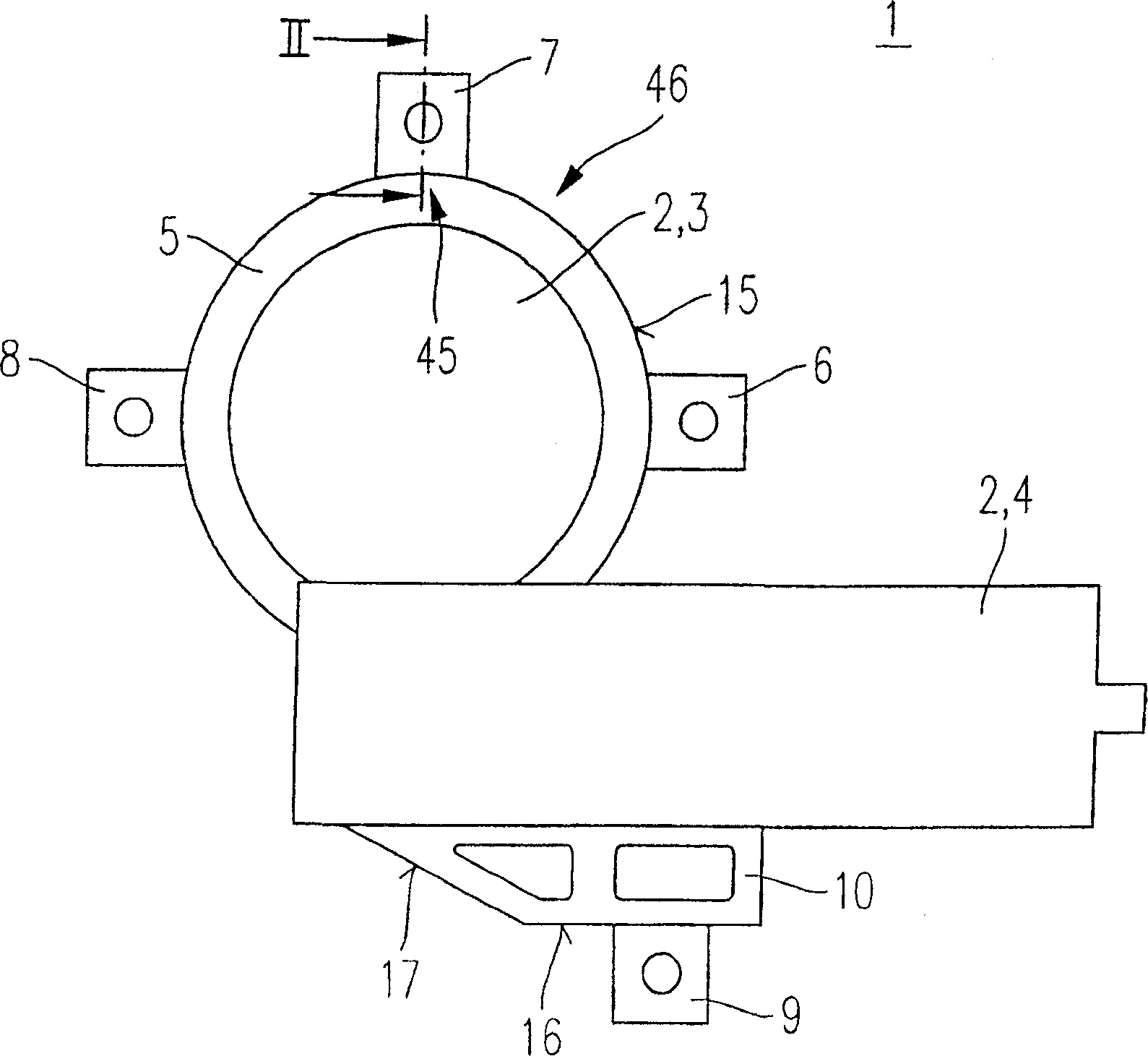

[0016] figure 1 A first embodiment of a transmission drive unit 1 of the invention is shown. The transmission drive unit 1 is particularly suitable for adjusting moving parts in a motor vehicle, for example for adjusting windows or sliding sunroofs. However, the transmission drive unit 1 according to the invention is also suitable for other applications.

[0017] The transmission drive unit 1 comprises a housing part 2 which is assembled from a transmission housing part 3 and a drive housing part 4 . The transmission housing part 3 of the housing part 2 has an annular segment 5 interrupted in the region of the drive housing 4 of the housing part 2 . The transmission housing part 3 is provided with fastening covers 6 , 7 , 8 , and a fastening cover 9 is fastened to the drive housing part 4 via a fastening element 10 which is part of the housing part 2 .

[0018] The fastening bells 6 , 7 , 8 can be moved along the circumference 15 of the ring segment 5 before being fastened ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap