Self-unloading transfer carrier

A carrier and self-unloading technology, which is applied in loading/unloading, unloading devices, transportation and packaging, etc., can solve the problems of unsatisfactory transportation needs, small corrugated boxes, and increased transportation costs, so as to improve the flexibility of use, The effect of reducing the amplitude of shaking and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in the scope of the present invention without any other embodiments obtained without creative labor.

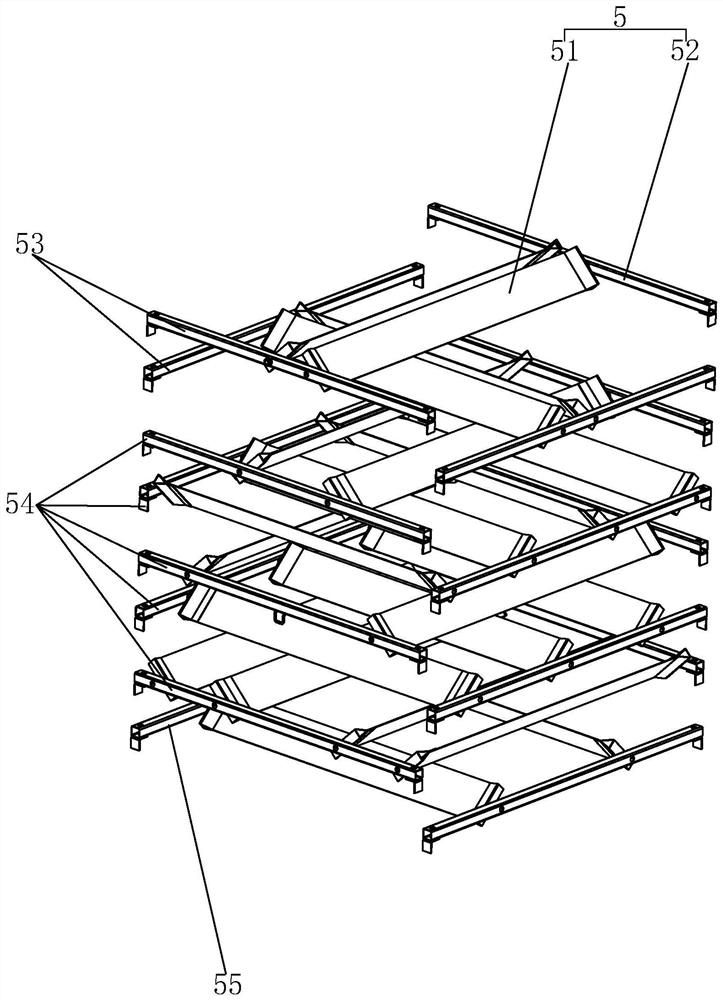

[0033] See Figure 1 to 4 The present invention provides a technical solution: a self-transfer carrier comprising a chassis 1, a chassis 1 fixedly coupled with a column 2, and four columns 2 are provided, four columns 2 are located in the chassis 1. At the top angle; the top end of the column 2 is fastened to the dust cover 3, and the dust cover 3 includes a frame 31, and the frame 31 is fixedly coupled to the column 2, and the border 31 slides the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com