Excavator getting off length adjustment system and excavator

A technology of length adjustment and excavator, which is applied in the direction of motor vehicles, crawler vehicles, transportation and packaging, etc. It can solve the problem that the excavator cannot adjust the grounding specific pressure, and achieve the effect of ensuring stability and reducing the grounding specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

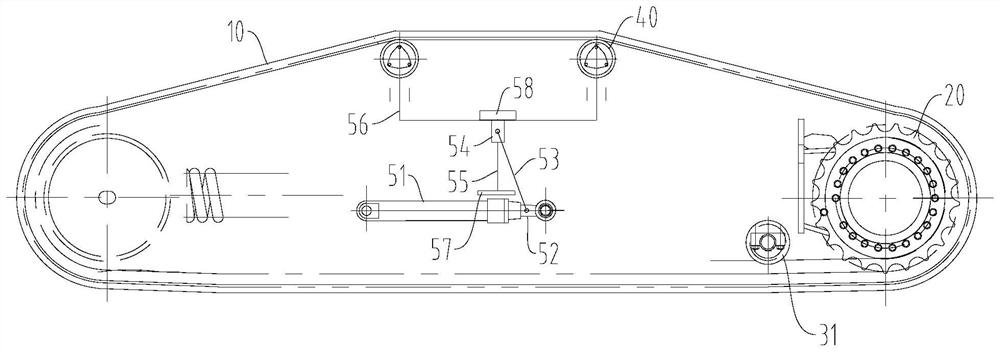

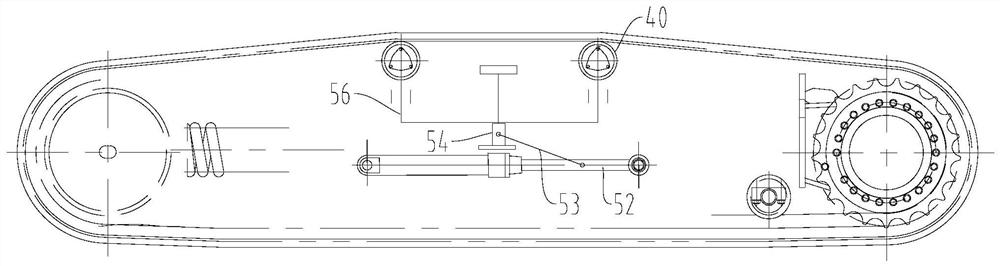

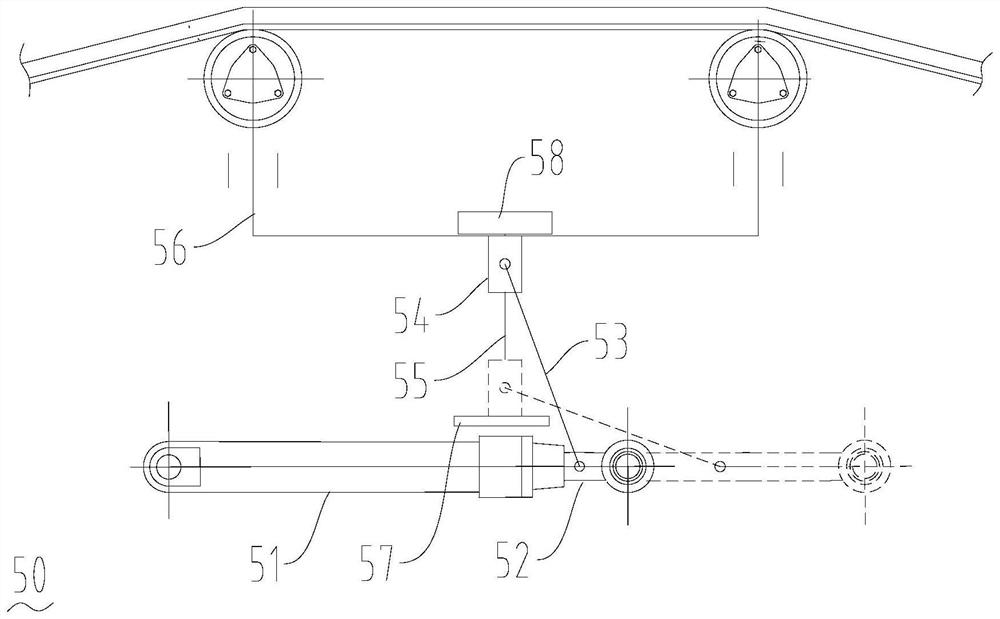

[0060] The excavator getting off length adjustment system provided in this embodiment includes:

[0061] Get off the walking beam;

[0062] The crawler belt 10 is set around the walking beam for getting off the vehicle;

[0063] The adjustment assembly 50 is adapted to adjust the length of the undercarriage traveling beam and adjust the height of the crawler belt 10 along the longitudinal direction accordingly;

[0064] The adjustment assembly 50 has the extension state of driving the getting off the walking beam to elongate while driving the crawler belt 10 down in the longitudinal direction, and the shrinking state of driving the getting off running beam to shorten while driving the crawler belt 10 to rise in the longitudinal direction state.

[0065] It should be noted that the disembarking walking beam is an important part of the excavator's traveling device, which is symmetrically arranged on both sides of the bottom of the excavator, used to install the traveling motor...

Embodiment 2

[0119] combine Figure 1-Figure 8 As shown, the present embodiment provides an excavator, including:

[0120] Slewing platform, operating room, working arm, and lower frame 60;

[0121] And the above-mentioned excavator getting off length adjustment system arranged on the lower frame 60 .

[0122] The excavator provided in this embodiment overcomes the defect that the excavator in the prior art cannot adjust the grounding specific pressure by setting the length adjustment system for getting off the car, and by adjusting the length of the getting off the car. Excavators that need to adjust the grounding specific pressure increase the stability of the excavator during work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com