Automatic carrying equipment for food materials

A technology for handling equipment and materials, applied in the field of automatic handling equipment for food materials, can solve the problems of inability to discharge materials, inability to effectively shock-proof food materials, and inability to realize automatic ejection of food materials, etc., to facilitate transportation and reduce economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

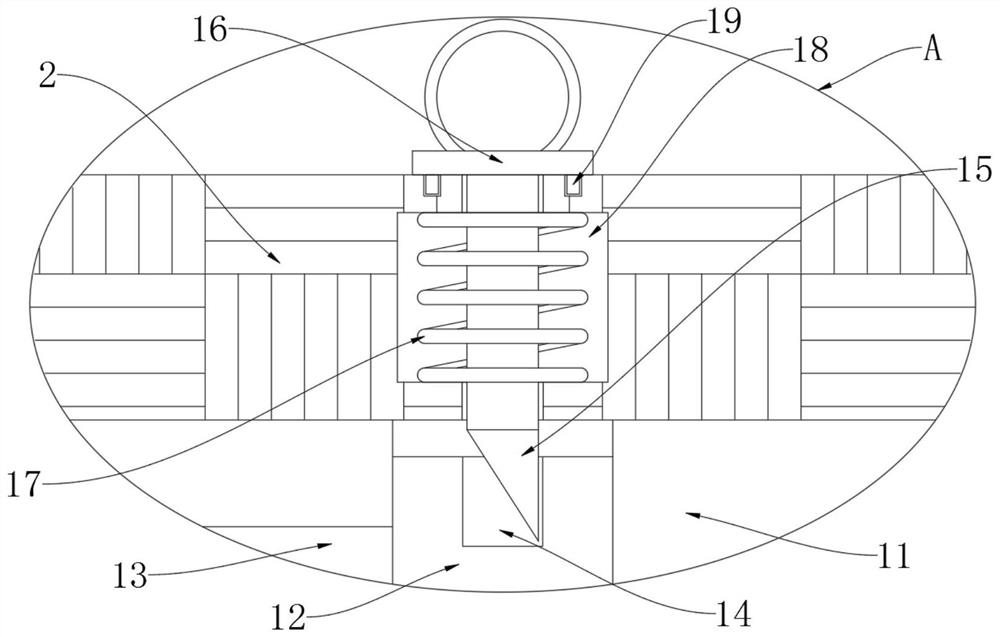

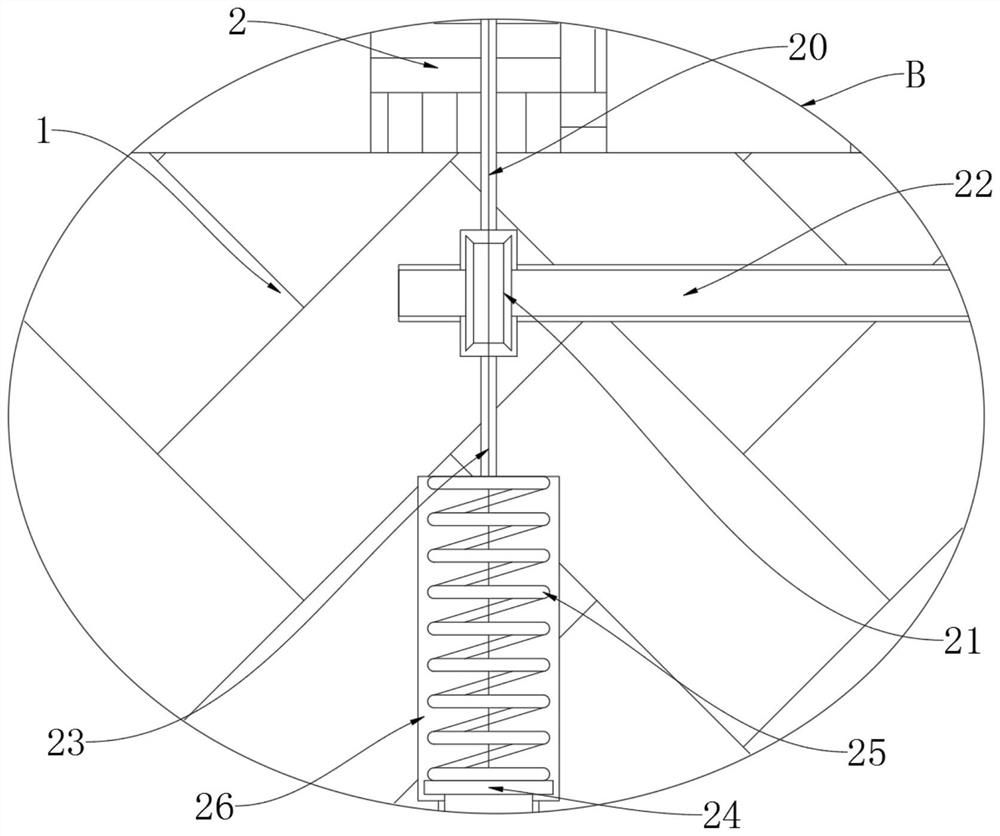

[0027] refer to Figure 1-6 , an automatic food material handling equipment, including a bottom plate 1, a buffer air bag 7, and a pushing device and a braking device arranged on the top of the bottom plate 1;

[0028] Pushing device comprises material box 8, fixed block 9, connecting rod 10, slide block 29, rotating rod 22 and back-moving spring 30 and driving mechanism; The bottom of material box 8 is fixedly connected with the top of fixed block 9; The bottom of fixed block 9 is movable Connecting rod 10 is connected, and the top of connecting rod 10 rotates at the bottom of fixed block 9; The bottom of connecting rod 10 is movably connected with slide block 29, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com