A kind of manufacturing die structure of rubber buffer ring

A buffer ring and compression molding technology, which is applied to household appliances, household components, other household appliances, etc., can solve the problems of mass production of unfavorable rubber buffer rings, direct removal of rubber edges, and labor-intensive work to remove rubber edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

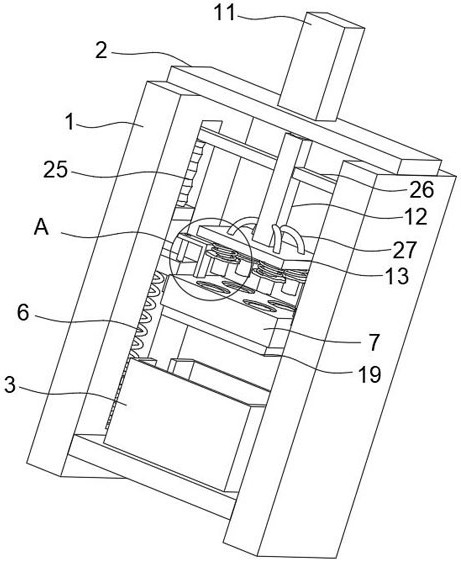

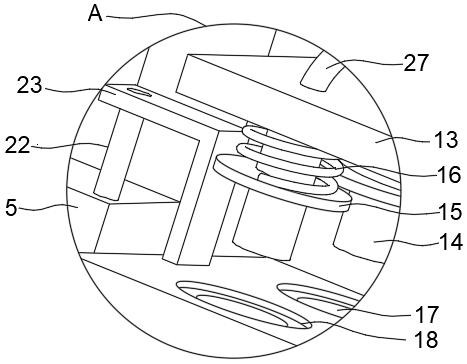

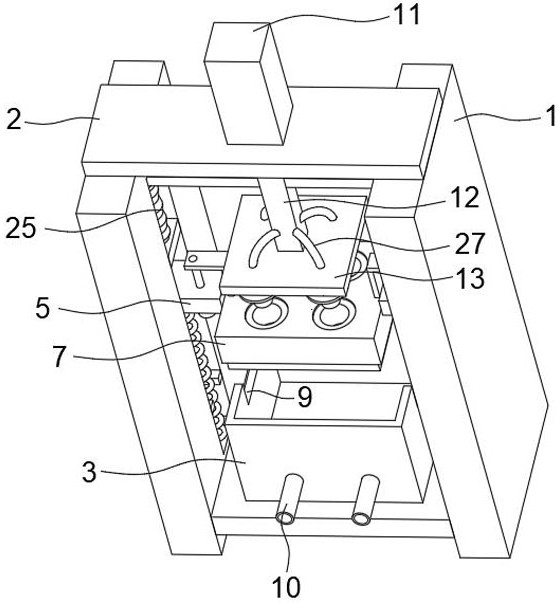

[0030] refer to Figure 1-7 , a die structure for making a rubber buffer ring, comprising two support plates 1 arranged opposite to each other on the left and right, the upper ends of the two support plates 1 are jointly fixedly connected to the installation plate 2, and a cooling water tank 3 is arranged between the two support plates 1 for cooling The water tank 3 is equipped with cooling water, which is used for rapid cooling and forming of the rubber buffer ring after compression molding. The opposite sides of the two support plates 1 are provided with chute 4, and the two chute 4 are slidingly connected with moving blocks 5, each A first spring 6 is fixedly connected between the moving block 5 and the inner bottom wall of the chute 4, and a mold block 7 is fixedly connected between the two moving blocks 5, and the mold block 7 can be moved under the action of the two moving blocks 5. Moving up and down along the chute 4, there are grooves 9 on both sides of the upper end ...

Embodiment 2

[0037] Compared with Embodiment 1, the improvement of this embodiment is that a fixed block 24 is fixedly connected in the two chutes 4 and above the moving block 5, and an air bag 25 is fixedly connected to the upper end of the fixed block 24, and the air bag 25 is used to absorb and exhaust air, both sides of the steel pipe fitting 12 are fixedly welded with connecting pipe fittings 26, and the ends of the two connecting pipe fittings 26 away from the steel pipe fitting 12 extend to the upper end of the corresponding air bag 25 and are fixedly connected with it, and can be fixedly connected to it by a hydraulic cylinder 11 When driving the steel pipe fitting 12 to move down, utilize the connecting pipe fitting 26 to press down the air bag 25; Cut off the rubber edge, a plurality of air holes 28 are provided in the circular groove, and the air holes 28 are used to discharge air. On the steel pipe fitting 12 and below the connecting pipe fitting 26, there are four arc-shaped pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com