A damping and anti-vibration supporting device for the turning processing of crane cylindrical parts

A technology for supporting devices and cylindrical parts, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as cutting vibration, vibration knife lines, secondary vibration knife, etc., to improve processing quality and reduce The effect of small vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings in the embodiments of the present invention. In the description, it should be understood ", "Right" and other indicated orientations or positional relationships are only corresponding to the drawings of the present invention. In order to facilitate the description of the present invention, they do not indicate or imply that the referred device or element must have a specific orientation:

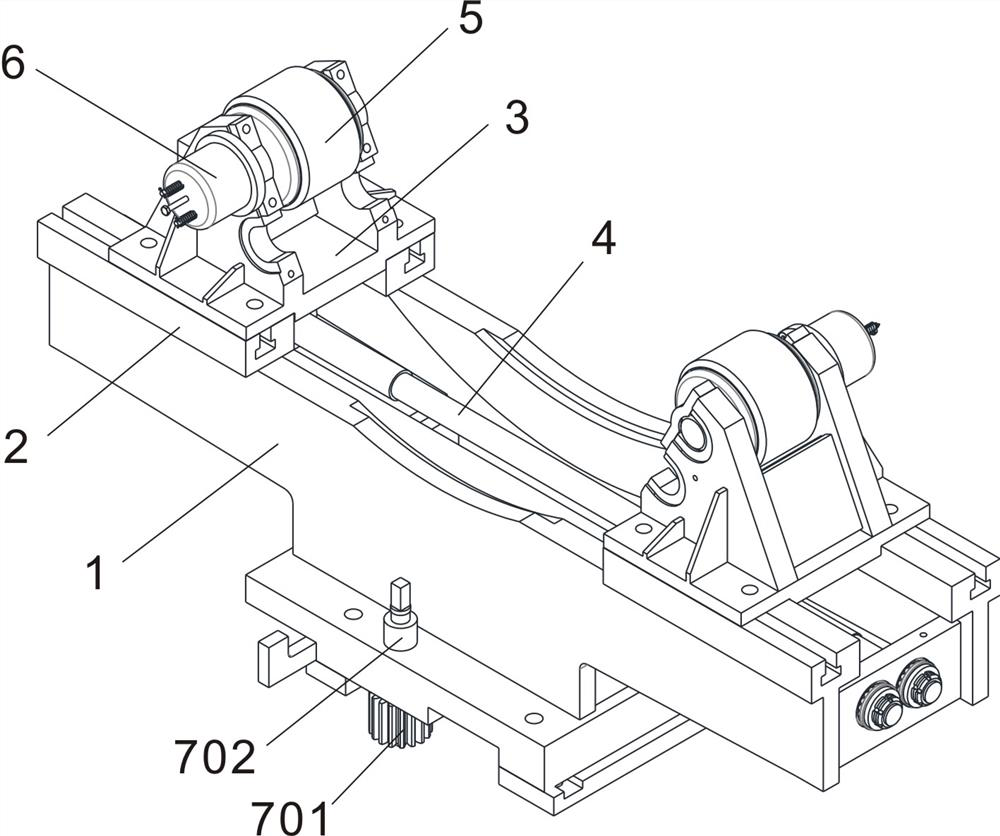

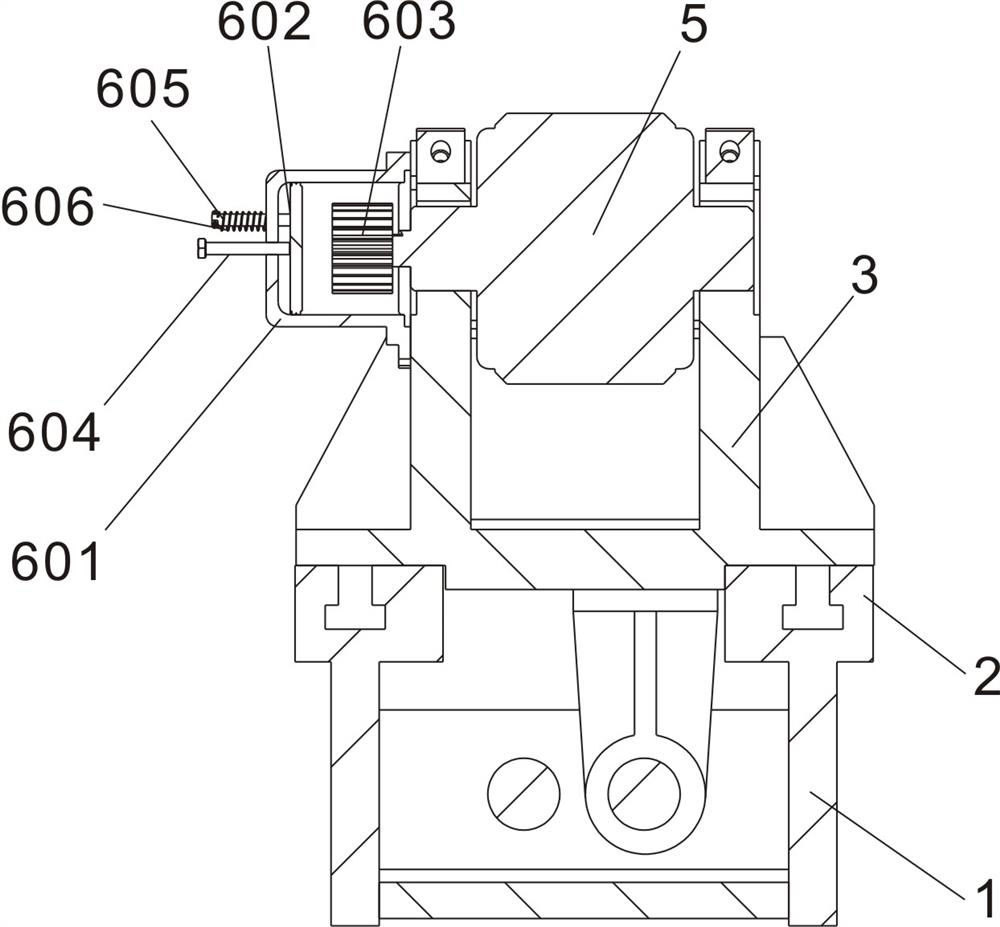

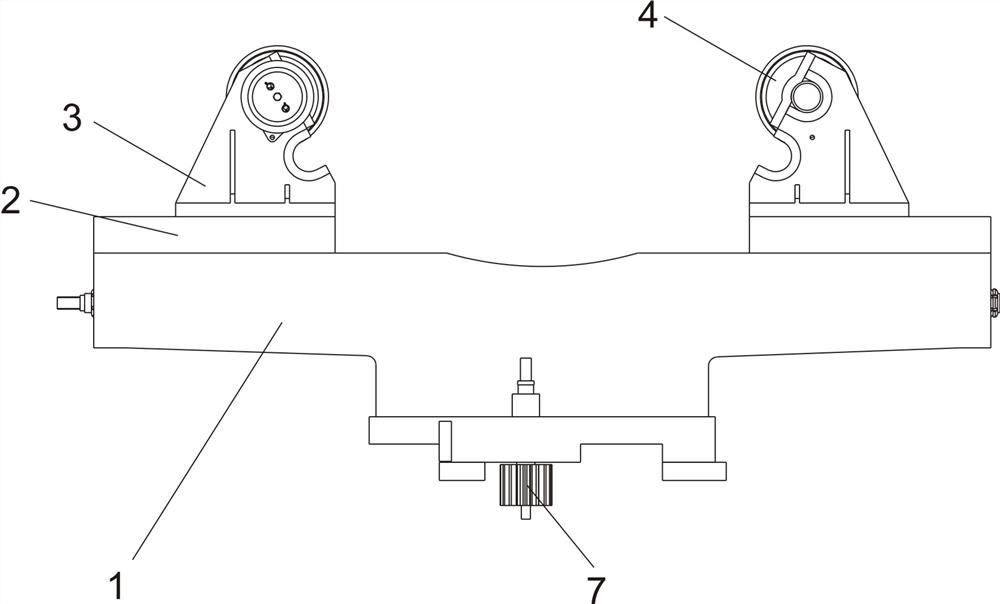

[0024] combined with Figure 1-4 The damping and anti-vibration supporting device for the turning processing of a crane cylindrical part includes a base 1, a slide rail 2, a sliding seat 3, a driving mechanism 4, a support wheel 5 and a rotation damping mechanism 6, and the bottom of the base 1 The surface and the guide rail of the lathe are correspondingly slidably connected, that is, the base 1 can move along the axial direction of the cylinder, thereby adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com