Carbonization equipment for processing silicon-carbon negative electrode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problem of heat attached to the inner surface of the carbonization furnace, poor compatibility between graphite and electrolyte, and affecting the carbonization of the device. effect and other issues, to achieve the effect of saving stirring time, avoiding local overheating, and improving drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

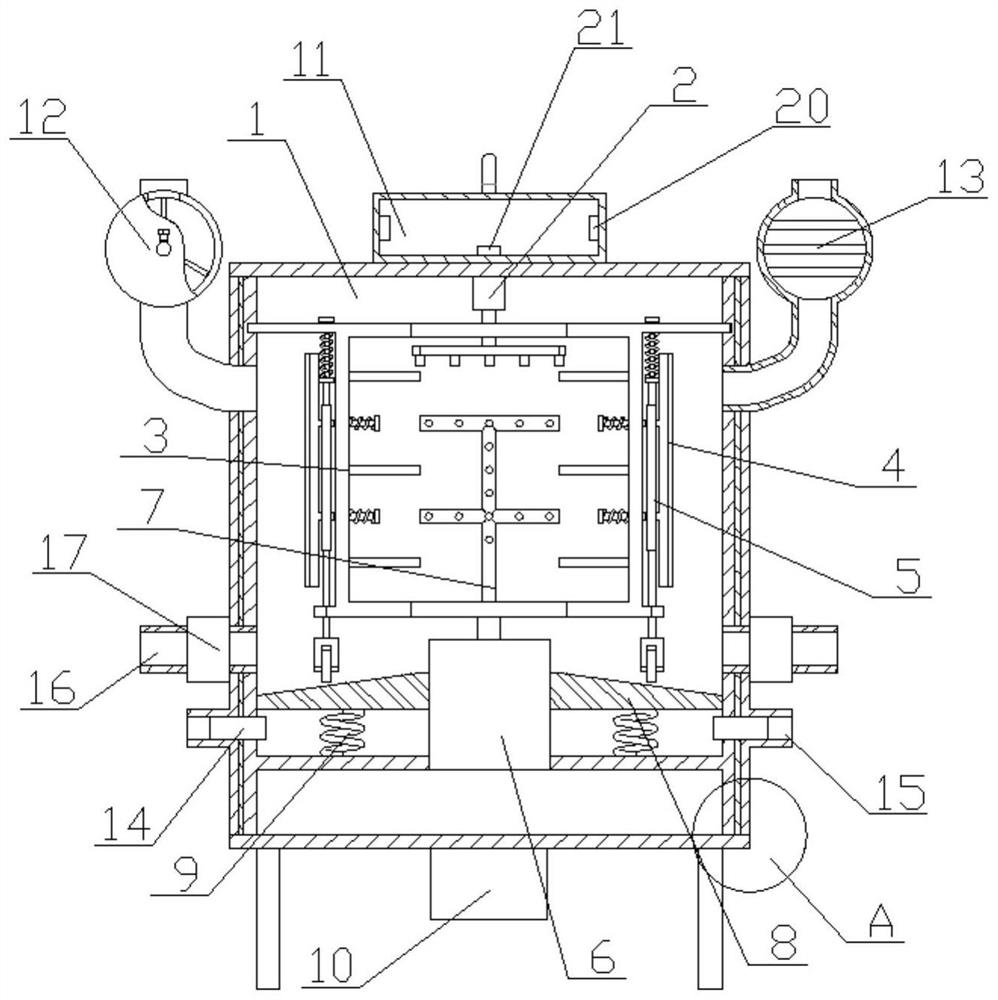

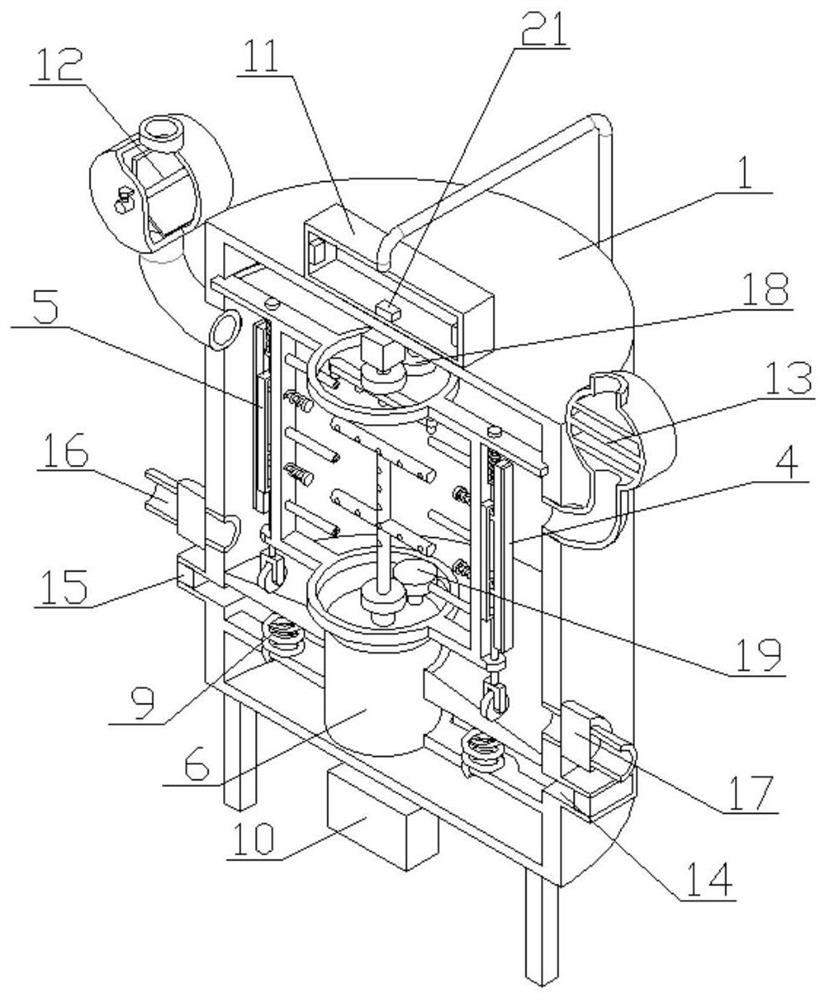

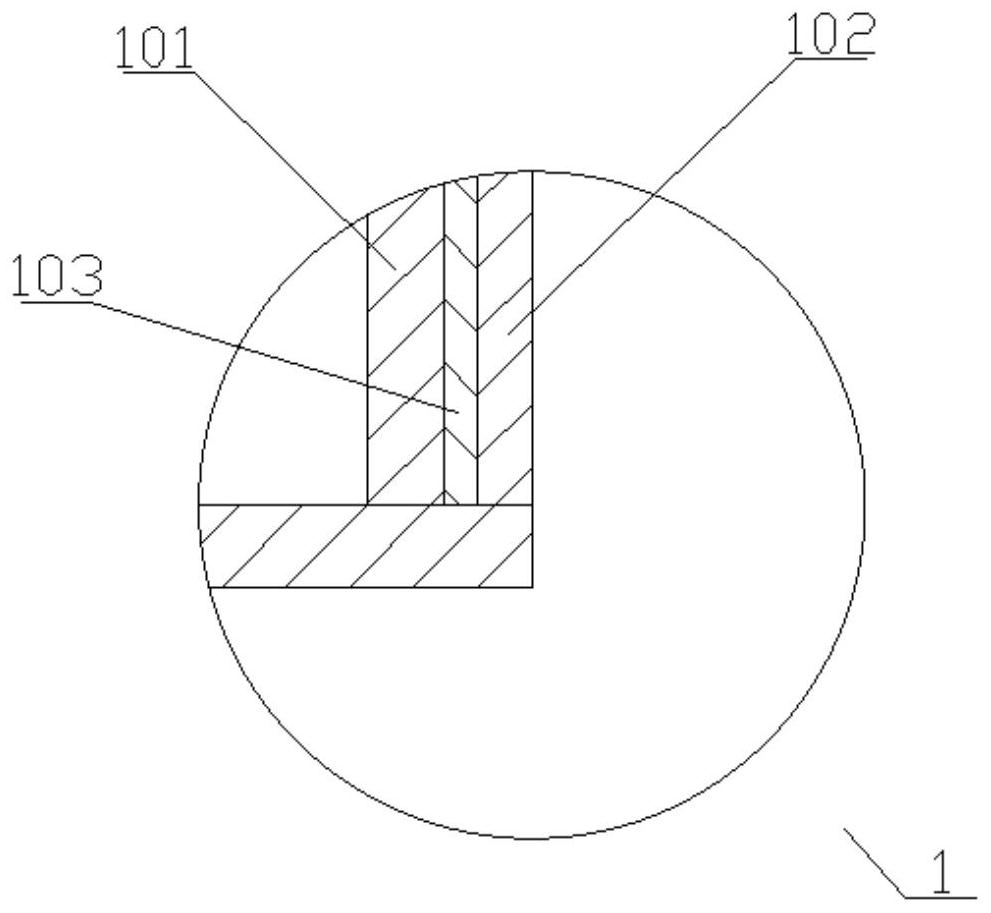

[0032] Combine below Figure 1-10 Describe the specific embodiment of the present invention, a carbonization equipment for lithium ion battery silicon carbon negative electrode material processing, including a box mechanism 1, a stirring mechanism 3 that is rotatably connected to the box mechanism 1, and fixedly connected to the box mechanism 1 the spray mechanism 2 on the upper side of the interior, the fixed bracket 6 fixedly connected to the lower side inside the box mechanism 1 and the weighing plate 8 slidingly connected between the box mechanism 1 and the fixed bracket 6, The spraying mechanism 2 is connected by transmission with the stirring mechanism 3, the stirring mechanism 3 is provided with a wall scraping mechanism 4 and a limiting mechanism 5, the fixed bracket 6 is rotatably connected with a drying mechanism 7, the The drying mechanism 7 is connected by transmission with the stirring mechanism 3, a first spring 9 is arranged between the weighing plate 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com