Vacuum puffing rapid extraction system and extraction method

A vacuum puffing and extraction technology, applied in chemical instruments and methods, separation methods, solvent extraction, etc., can solve the problems of bitterness and aroma loss, energy and time consumption, and long time consumption, so as to enhance visual impact and save energy Loss and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. It is to be understood, however, that many of the details set forth in the specification are merely provided to provide the reader with a thorough understanding of one or more aspects of the invention, and that aspects of the invention may be practiced without these specific details.

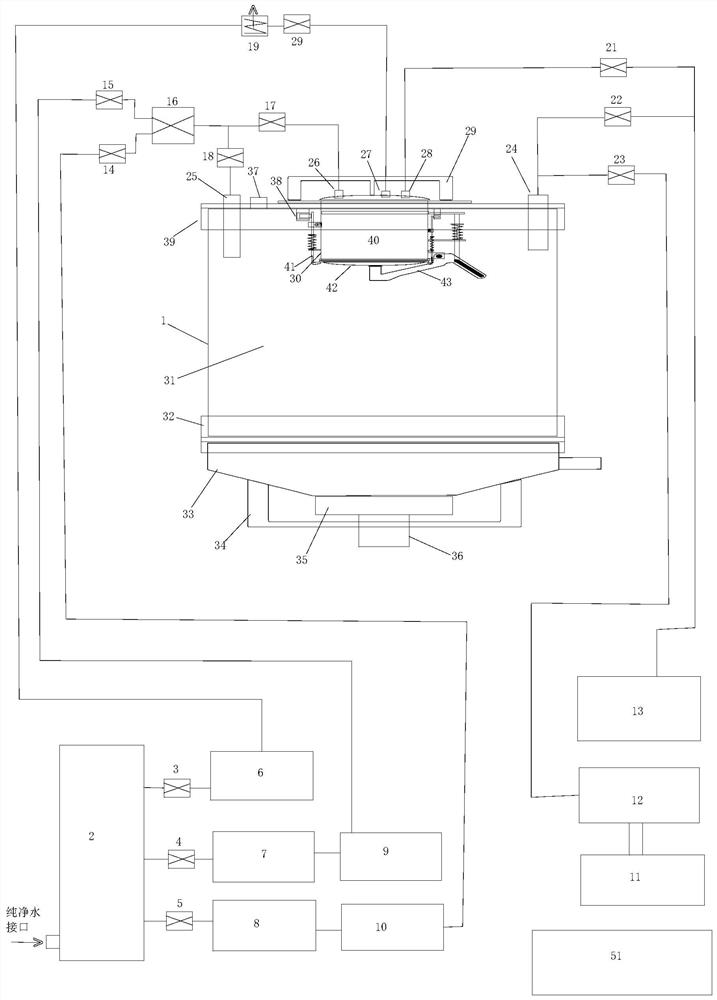

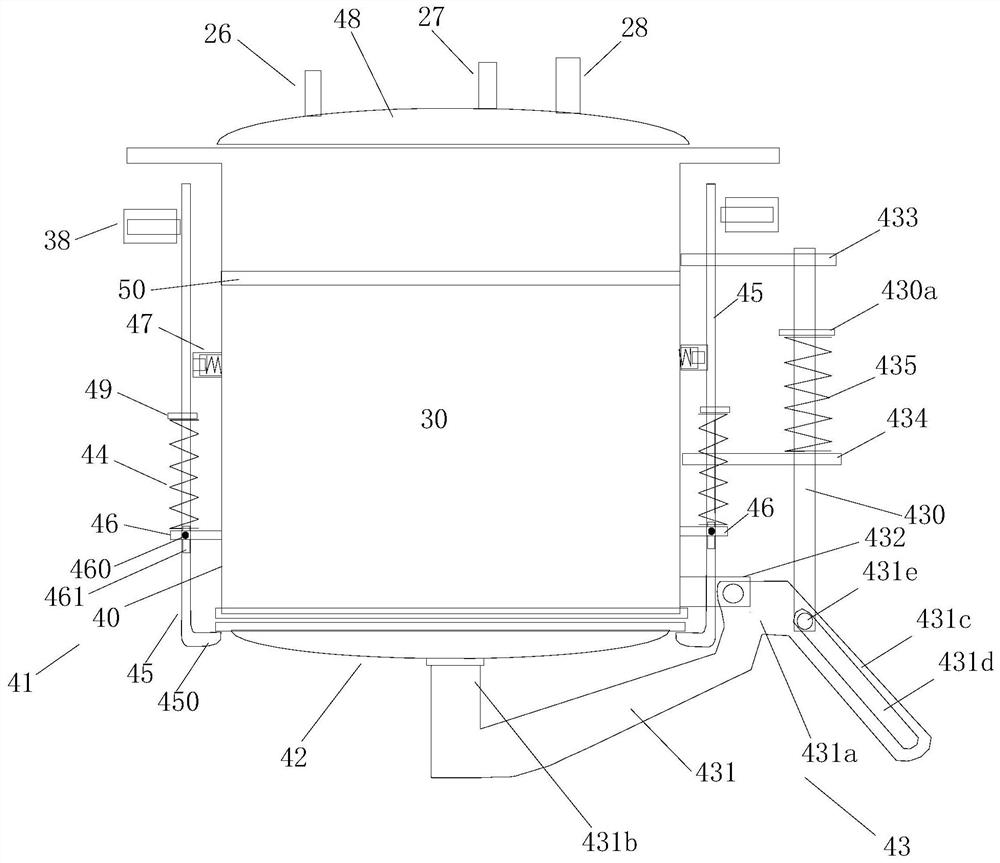

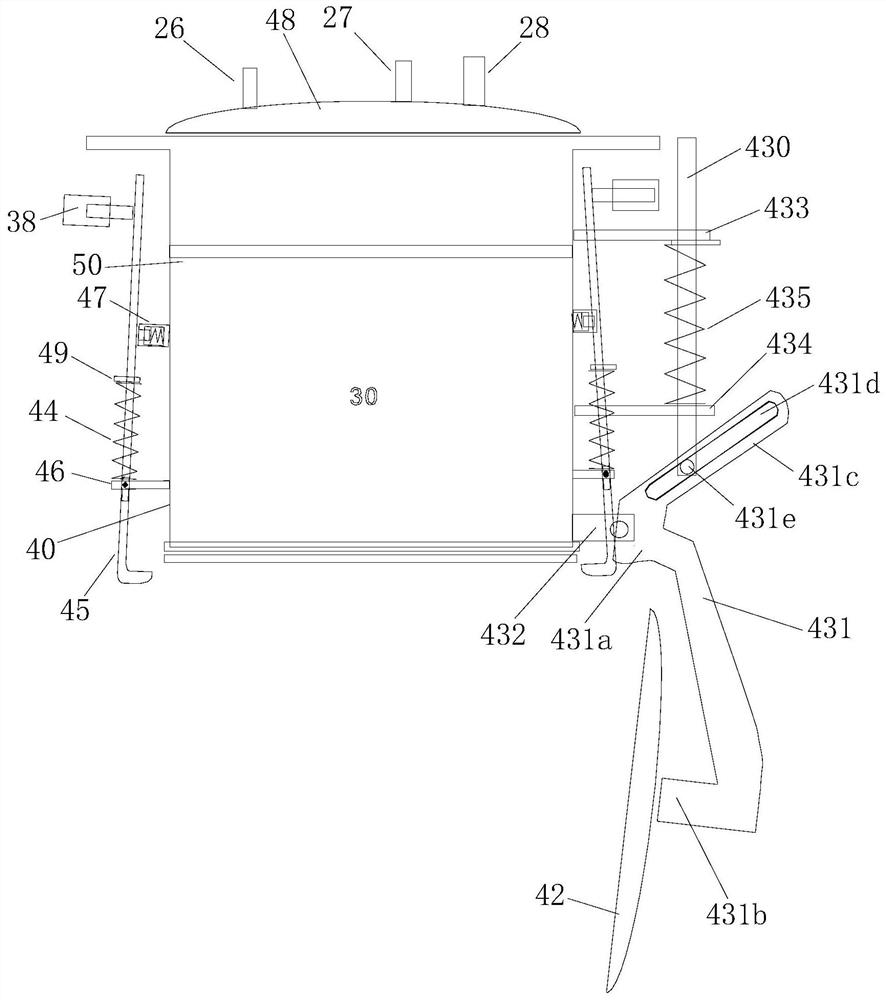

[0025] like figure 1 As shown, this embodiment provides a vacuum puffing rapid extraction system, including a vacuum puffing extraction tank 1, a water replenishing unit, an air compressor 12, a vacuum pump 13 and a steam pressure tank 30, and the vacuum puffing and extraction tank 1 is fixed in a vertical direction. , the upper and lower ends of the vacuum puffing extraction tank 1 are open, and the lower open end of the vacuum puffing extraction tank 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com