Coal bed gas fracturing method suitable for multiple sets of high-steep crushed coal beds

A coal seam and fracturing technology, which is applied in the field of hydraulic fracturing stimulation of coalbed methane, can solve the problems of lack of optimal layers and reasonable fracturing scales, and maximize the utilization of coalbed methane resources and economic benefits, and improve economic efficiency. Benefit, the effect of reducing the cost of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention will be described in detail below in conjunction with the following specific examples, but it should not be construed as limiting the scope of the present invention.

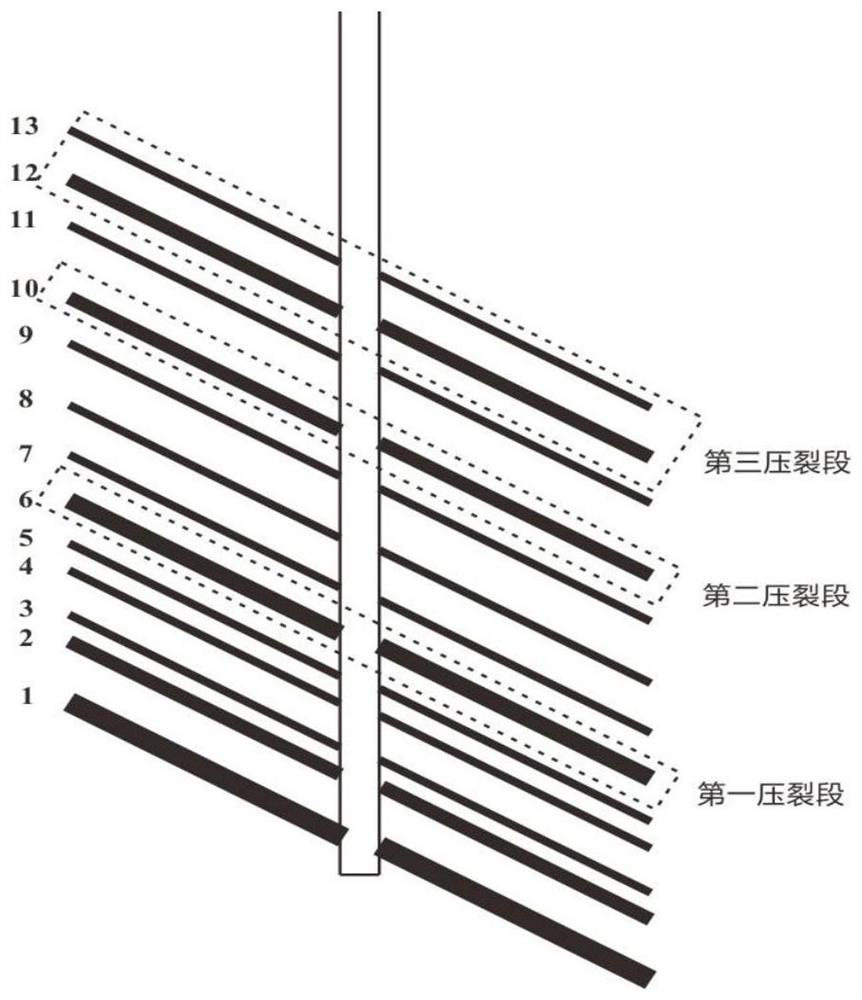

[0037] The fracturing method of the present invention is designed for granular coal with many coal seams and high inclination angle, and multi-layer coal seams and rocks are alternately formed. The method includes multiple steps such as coal preparation seam, coal preparation section, fracturing scale determination, fracturing material selection, perforation, pump injection, etc., and configures a reasonable fracturing scheme by optimizing the coal preparation seam and coal preparation section. It solves the problem that high and steep coal seam is easy to produce sand, and the cracks formed are too long, but cannot be effectively supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gas content | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com