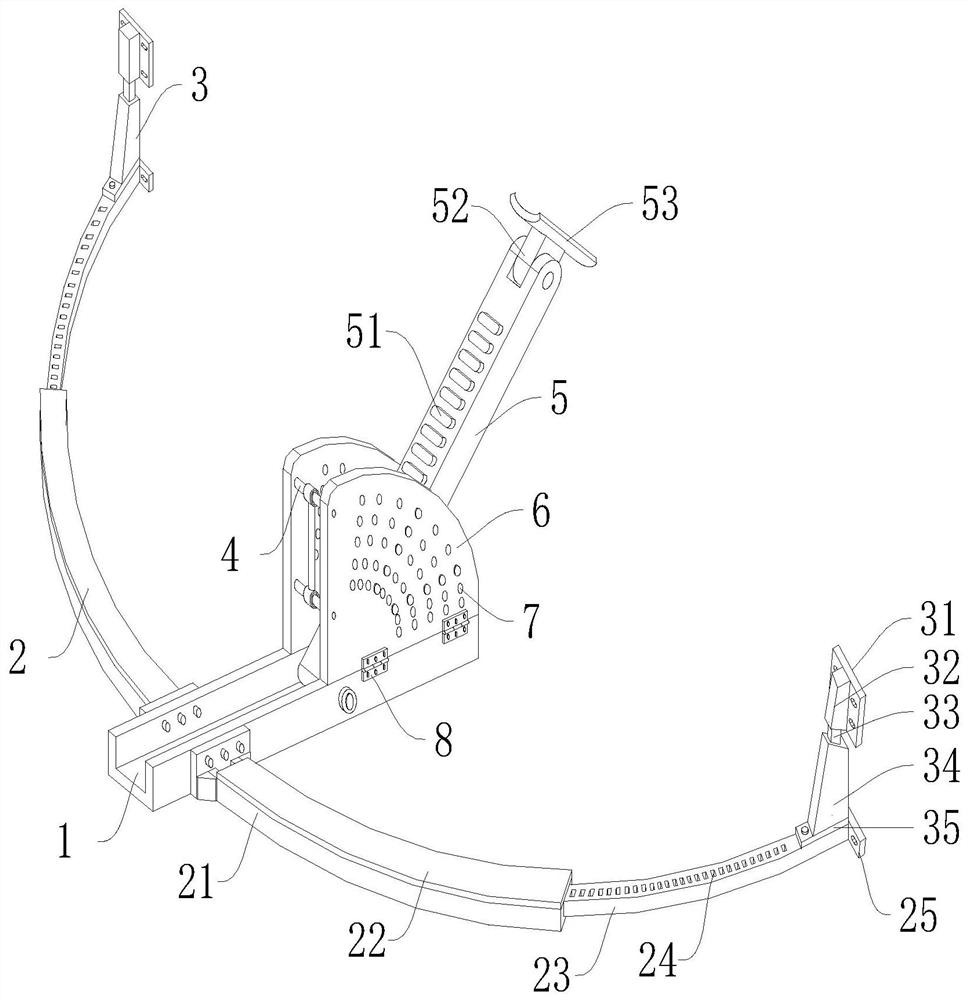

A multi-directional support and guide system for prefabricated building wall assembly

A building wall, support-oriented technology, applied in construction, building structure, processing of building materials, etc., can solve problems such as affecting the installation and use of bottom beams and inclined beams, increasing the deformation probability of bottom beams, and shaking, etc. Improve the use effect and lifespan, enhance the connection strength, and improve the support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

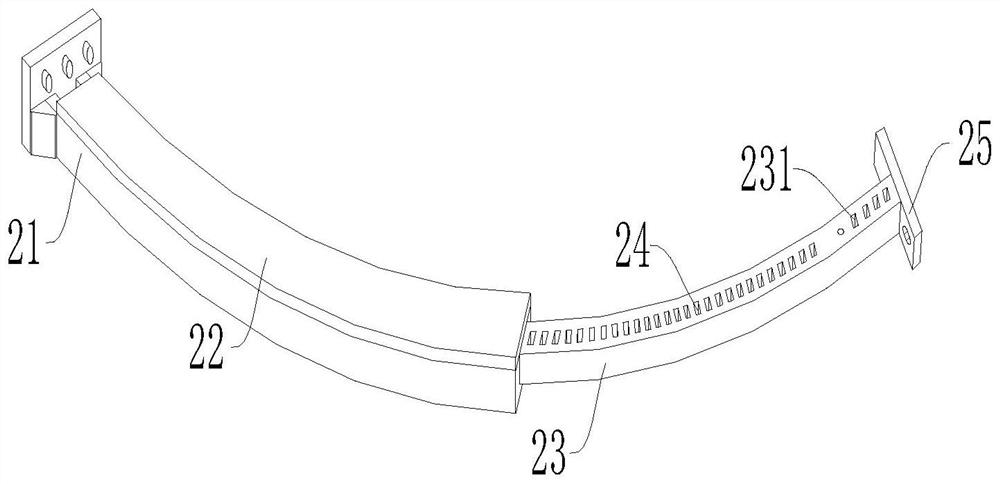

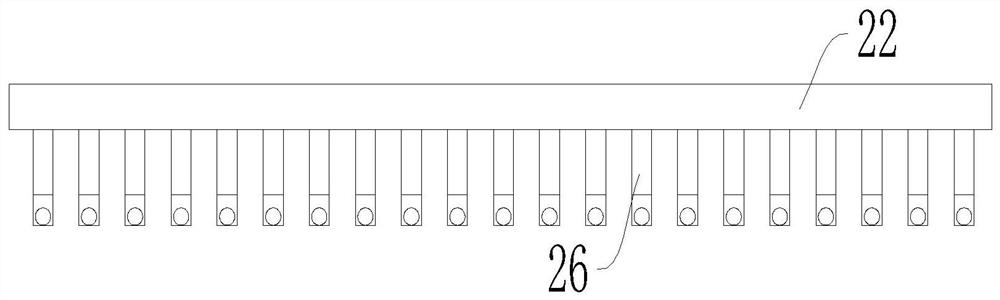

[0038] Specifically, firstly, two prefabricated walls are hoisted to the column installation position, and the U-shaped plate 1 is fixed to the appropriate position of the carrier, and then the support rod 5 is rotated around the rotating shaft to rotate the support rod 5 to the appropriate position, Then use the living hinge 52 to rotate the connecting plate 53, so that the connecting plate 53 and the wall column can be closely attached, and then the connecting plate 53 and the wall column are installed, so as to use the support rod 5, so that the wall can be installed. The vertical column is supported, and then the arc guide box 21 on the side guide mechanism 2 is fixed to the side end of the U-shaped plate 1, and then the fixed plate 25 on the arc moving plate 23 of the side guide mechanism 2 is assembled with the side The wall is fixed and installed, and then the angle adjustment operation is performed on the assembled wall on the side. During the process, the arc-shaped mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com