A pile-forming method of screw-extruding soil to form a hole and fixing the sleeve followed by pouring concrete

A technology of pouring concrete and fixing sleeves, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of inaccurate installation in the middle, and achieve the effect of stable structure and tight connection of land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

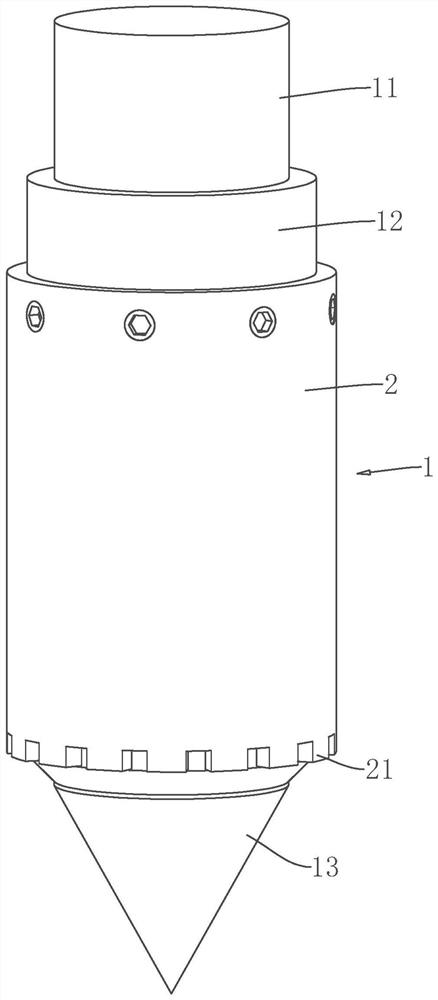

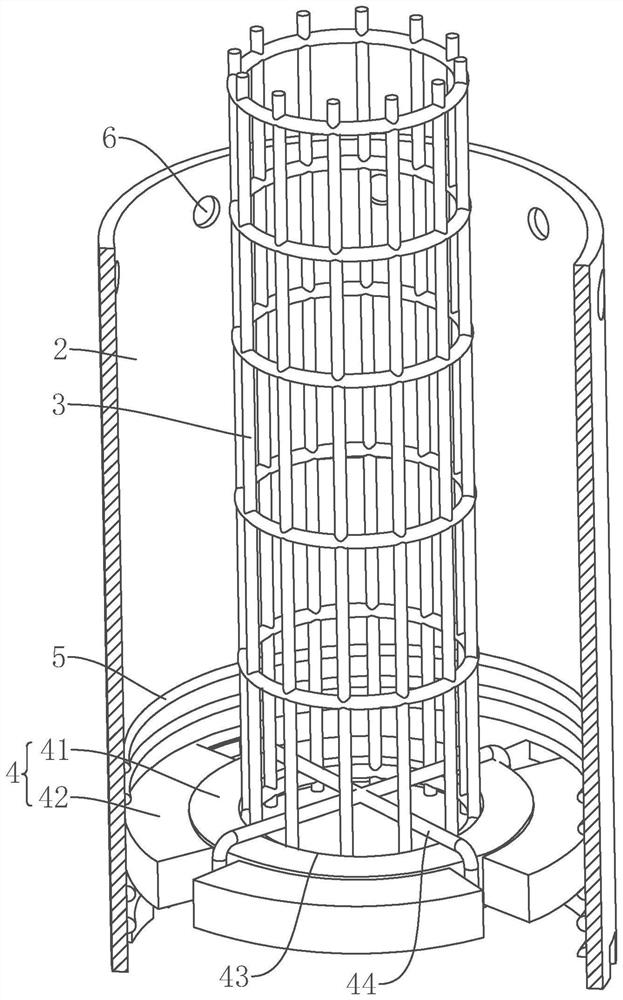

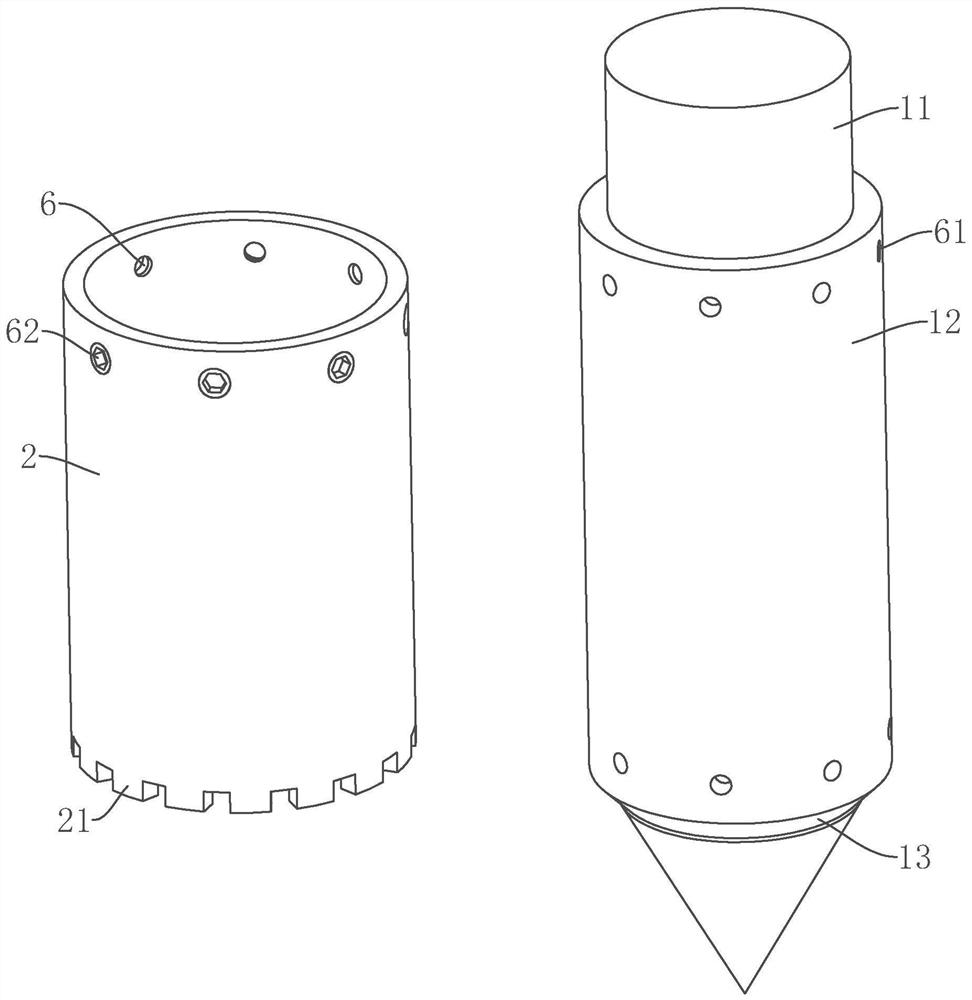

[0037] Attached to the following Figure 1-3 This application will be described in further detail.

[0038]The embodiment of the present application discloses a method for forming a pile with a screw-extruded soil to form a hole and a fixed sleeve followed by a poured concrete. refer to figure 1 and figure 2 , the screw extruding soil to form a hole and the fixed sleeve to follow up the pouring concrete pile method includes the following steps:

[0039] S1. Install two sets of soil extruding power heads 1 on the screw extruding soil pile machine. The two sets of soil extruding power heads 1 are respectively the first power head 11 and the second power head 12. The first power head 11 is cylindrical, and the second power head 11 is cylindrical. The power head 12 is cylindrical, the second power head 12 is sleeved on the outer side of the first power head 11 , and the lower ends of the first power head 11 and the second power head 12 are equipped with a soil extruding bit 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com