Sodium acetate trihydrate phase change heat storage material and preparation method thereof

A phase-change heat storage material, sodium acetate trihydrate technology, applied in the field of energy storage materials, can solve the problems of large crystallization supercooling, achieve the effects of improving thermal conductivity, improving heat storage/dissipating efficiency, and reducing supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

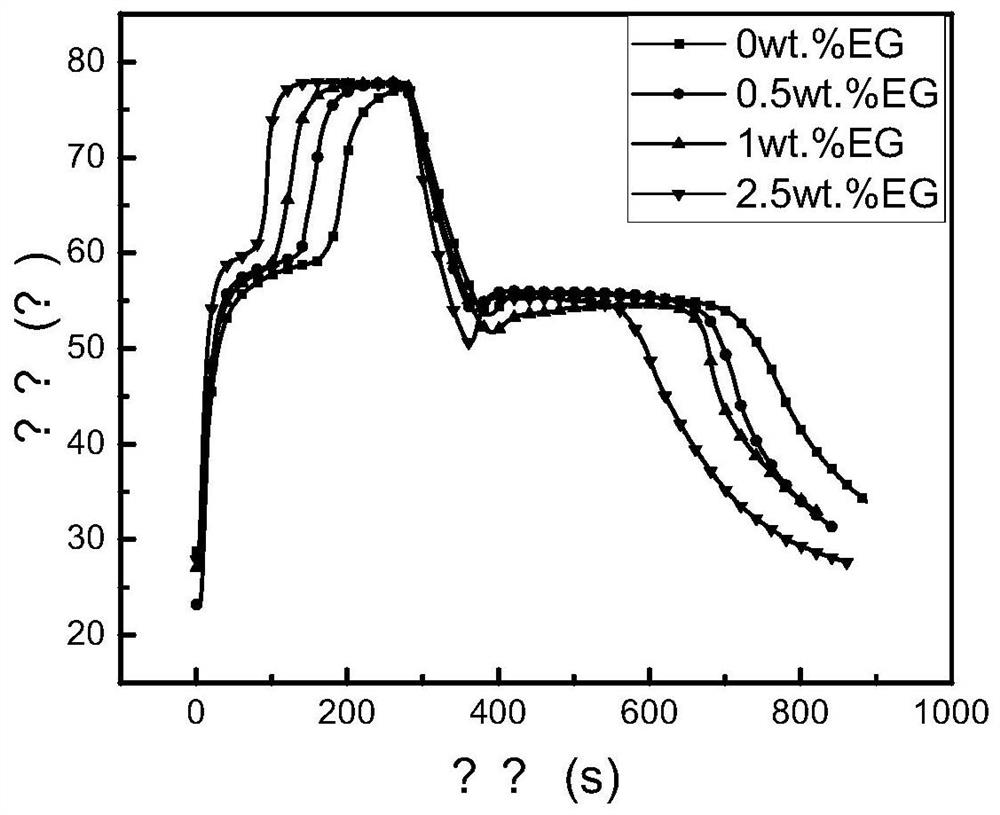

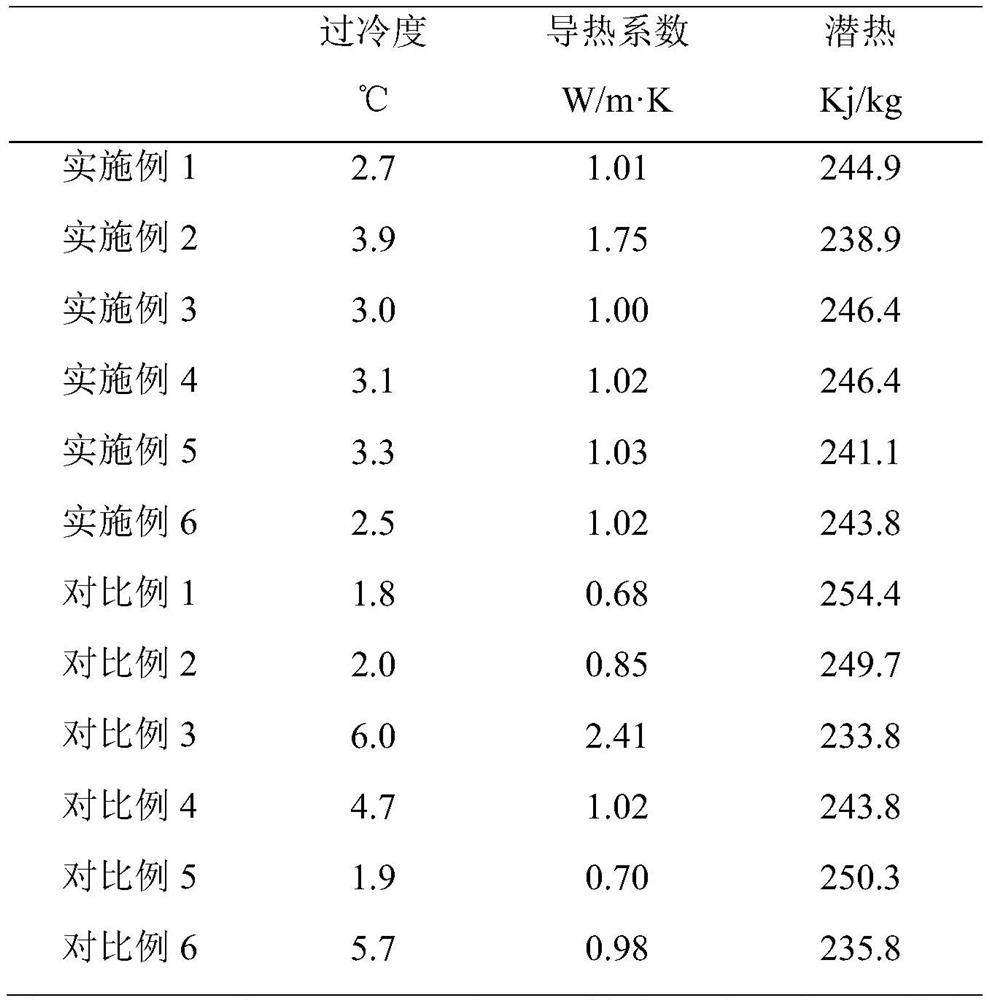

[0024] Sodium three aquatic acetate phase change heat storage material consists of 95% sodium three aquatic acetate, 2% diq. Sodium hydrogen phosphate, 2% and 1% expansion graphite, and the preparation method is as follows:

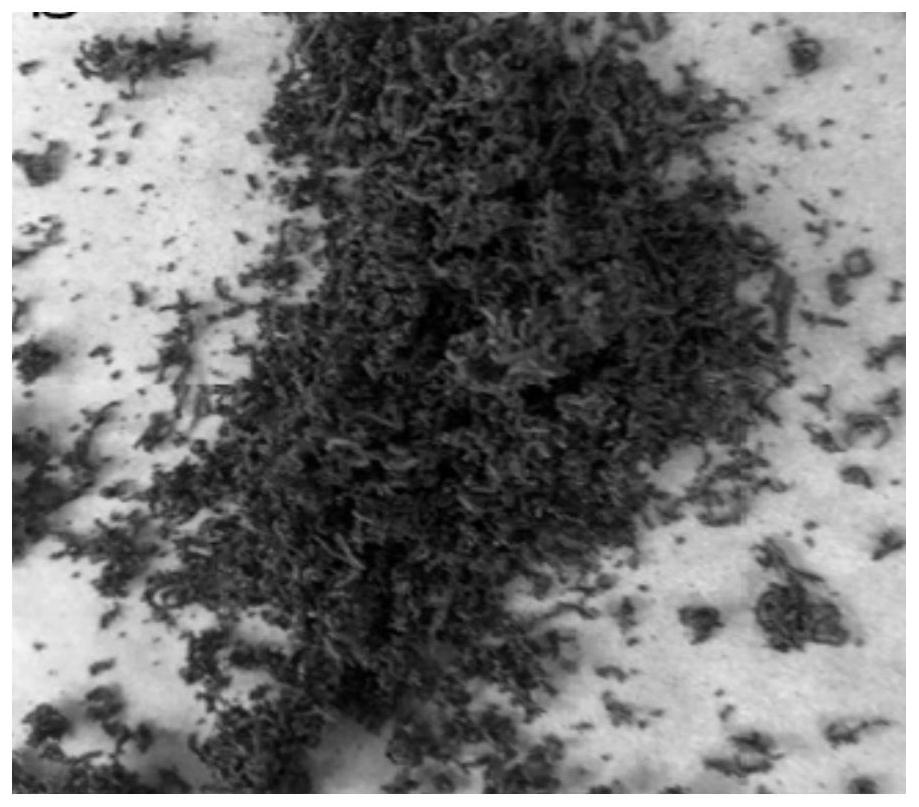

[0025] (1) Prepare the expansion graphite in the high temperature furnace of 900 ° C;

[0026] (2) Mix sodium three aquatic acetate 10g and diethodium hydrogen phosphate sodium hydrogen phosphate is mixed into the sample bottle, and the sample bottle is placed in a water bath in 75 ° C, the sample is melted after 10 min;

[0027] (3) Sample bottle is placed in a water bath in 75 ° C, while stirring, 0.21 g of carboxymethylcellulose is slowly added, and stirring is continued for 15 min;

[0028] (4) Sample bottle is placed in a water bath in 75 ° C, while stirring, 0.105 g of expanded graphite is added, and stirred for 20 min, sodium three aquatic acetate, dihydrate sodium hydrogen phosphate, carboxymethylcellulose and expansion The graphite is mixed and unifo...

Embodiment 2

[0031] The present embodiment is substantially the same as that of Example 1, and the different sodium three aquatic acetate phase change heat storage material is 93.5%, dihydrate 2%, 2% sodium hydrogen phosphate, 2%, carboxymethyl cellulose, and expanded graphite. 2.5% consist. The expansion graphite is 0.267 g in step (4).

Embodiment 3

[0033] The present embodiment is substantially the same as that of Example 1, and the different sodium three aquatic acetate phase change heat storage material is 96% sodium three aquatic acetate, 1% sodium hydrogen phosphate is 1%, carboxymethylcellulose 2% and expansion. Graphite is 1% consisting. In step (2), there is 0.21 g of carboxymethyl cellulose in step (3) in step (3), and the graphite is expanded from 0.104 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com