Preparation method and preparation device of crude lactide and prepared crude lactide

A preparation device and lactide technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of high energy consumption, low yield of crude lactide, high acid and moisture content, etc., and achieve energy reduction consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

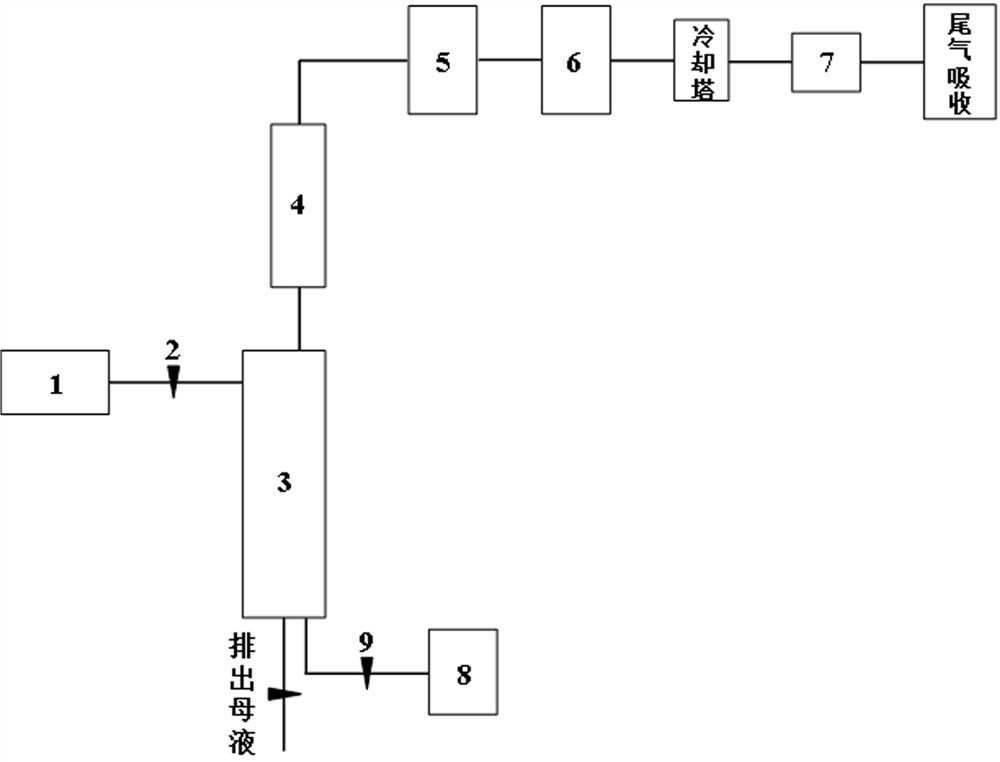

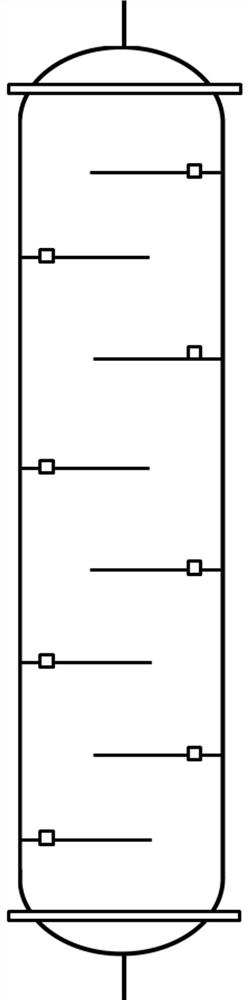

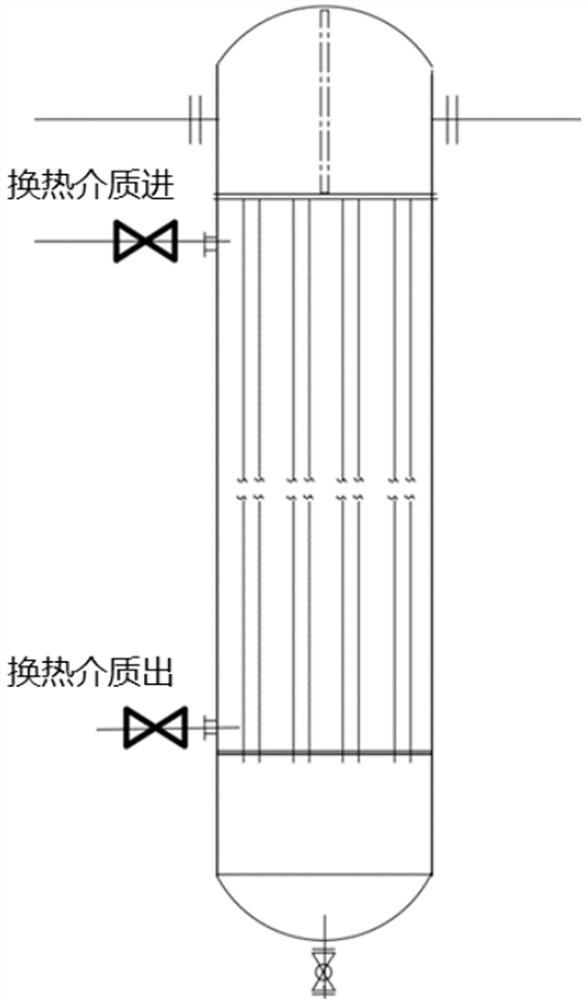

[0045] Turn on the vacuum unit 7 to keep the vacuum degree of the depolymerization system at 1000Pa, slowly adjust the flow regulating valve 2 to allow the depolymerization mother liquor to flow into the depolymerization reactor 3, adjust the temperature of the depolymerization reactor 3 to 210°C, and lactide begins to form The steam overflows, and the liquid content of the depolymerization reactor 3 is kept at 60% through the flow regulating valve 2, and the overflowing lactide steam is removed by the tower type gas-liquid separator 4 with 6 layers of trays at 120°C. The entrained lactic acid oligomers and heavy components pass through the first-stage double-flow heat exchanger 5 at 98°C to collect the main crude lactide, and further collect a small amount of crude lactide through the second-stage double-flow heat exchanger 6 at 90°C. crude lactide. As the depolymerization reaction proceeds, the viscosity of the mother liquor in the depolymerization reactor 3 increases gradua...

Embodiment 2-5

[0048] Using the same method steps as in Example 1, only the technical parameters are changed, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com