A permeable brick made of ceramsite

A technology of permeable bricks and ceramsite, which is applied in the field of building materials to achieve good water permeability, good water retention rate, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

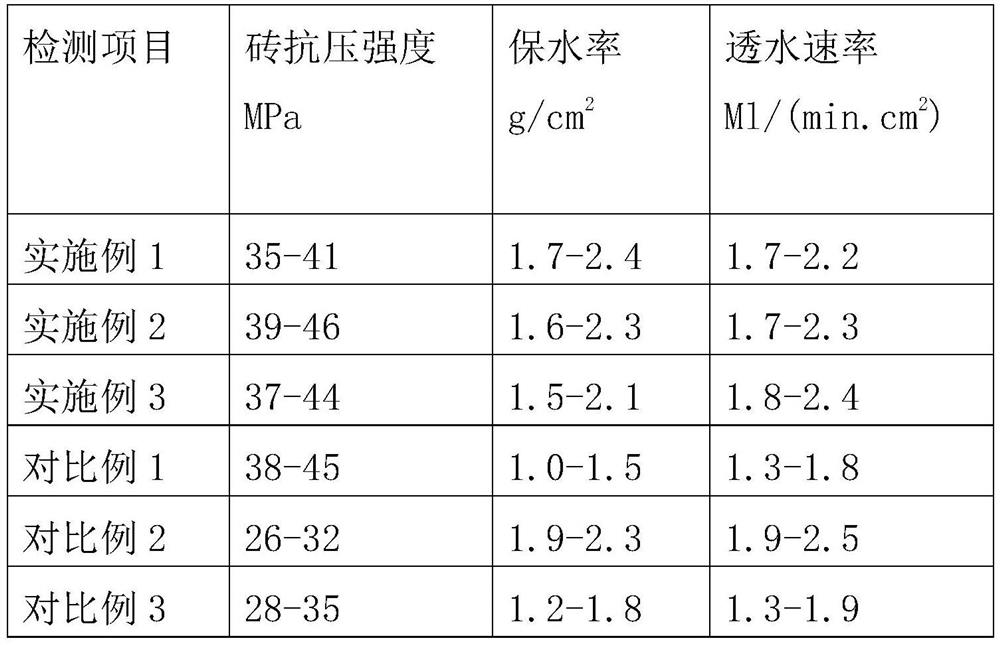

Examples

Embodiment 1

[0031] A permeable brick prepared by ceramsite, the preparation method is as follows:

[0032] 1. Preparation of ceramsite:

[0033] After mixing 65 parts of foundry dust, 15 parts of Portland cement, 5 parts of calcium oxide, 1 part of naphthalene sulfonate formaldehyde polymer, and 2 parts of inorganic aluminum salt, put it into a disc granulator, and add ceramsite. 5% water of the total weight of the raw materials is granulated to obtain pellets with a particle size of about 5 mm; the pellets are watered and maintained for 3 days under the condition of greater than 25° C. to obtain ceramsite.

[0034] 2. Preparation of permeable bricks

[0035] (1) Mixing: Mix 40 parts of ceramsite, 15 parts of crushed stone, 10 parts of silica sand, 10 parts of Portland cement, 0.15 part of lignosulfonate, and the mass of added water accounts for 10% of the total weight of the mixture to obtain Mixture;

[0036] (2) Brick making: pour the mixture into the brick mold and vibrate and extr...

Embodiment 2

[0039] A permeable brick prepared by ceramsite, the preparation method is as follows:

[0040] 1. Preparation of ceramsite:

[0041] After mixing 73 parts of foundry dust, 20 parts of Portland cement, 9 parts of calcium chloride, 1 part of polycarboxylate, and 1.5 parts of inorganic aluminum salt, put it into a disc granulator, and add the total amount of ceramsite raw materials. 12% by weight of water is used for granulation to obtain pellets with a particle size of about 7 mm; the pellets are watered and maintained for 3 days under the condition of greater than 25° C. to obtain ceramsite.

[0042] 2. Preparation of permeable bricks

[0043] (1) Mixing: Mix 50 parts of ceramsite, 25 parts of crushed stone, 10 parts of silica sand, 15 parts of Portland cement, 0.20 part of polycarboxylate, and the mass of water added accounts for 15% of the total weight of the mixture, and the mixture is obtained. material;

[0044] (2) Brick making: pour the mixture into the brick mold and...

Embodiment 3

[0047] A permeable brick prepared by ceramsite, the preparation method is as follows:

[0048] 1. Preparation of ceramsite:

[0049] After mixing 78 parts of foundry dust, 26 parts of Portland cement, 13 parts of desulfurization gypsum, 1.1 parts of naphthalene sulfonate formaldehyde polymer, and 1 part of inorganic aluminum salt, put it into a disc granulator, add ceramsite 10% of the total weight of the raw material is granulated with water to obtain pellets with a particle size of about 9 mm; the pellets are watered and maintained for 4 days at a temperature greater than 25° C. to obtain ceramsite.

[0050] 2. Preparation of permeable bricks

[0051] (1) Mixing: Mix 55 parts of ceramsite, 15 parts of crushed stone, 15 parts of silica sand, 20 parts of Portland cement, 0.15 part of melamine water-reducing agent, and the mass of added water accounts for 16% of the total weight of the mixture. get the mixture;

[0052] (2) Brick making: pour the mixture into the brick mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com