A treatment method for bpa-containing sewage and ball-milling modified magnetic biochar composite material

A composite material and processing method technology, applied in the field of ball milling modified magnetic biochar composite materials, can solve the problems of large surface crushing degree of ball milling modified material, increase the difficulty and cost of preparing materials, and exist ecological health and safety risks, etc. Conducive to large-scale promotion, improved removal performance, and stable degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The treatment method of BPA-containing sewage provided by the present embodiment comprises the following steps:

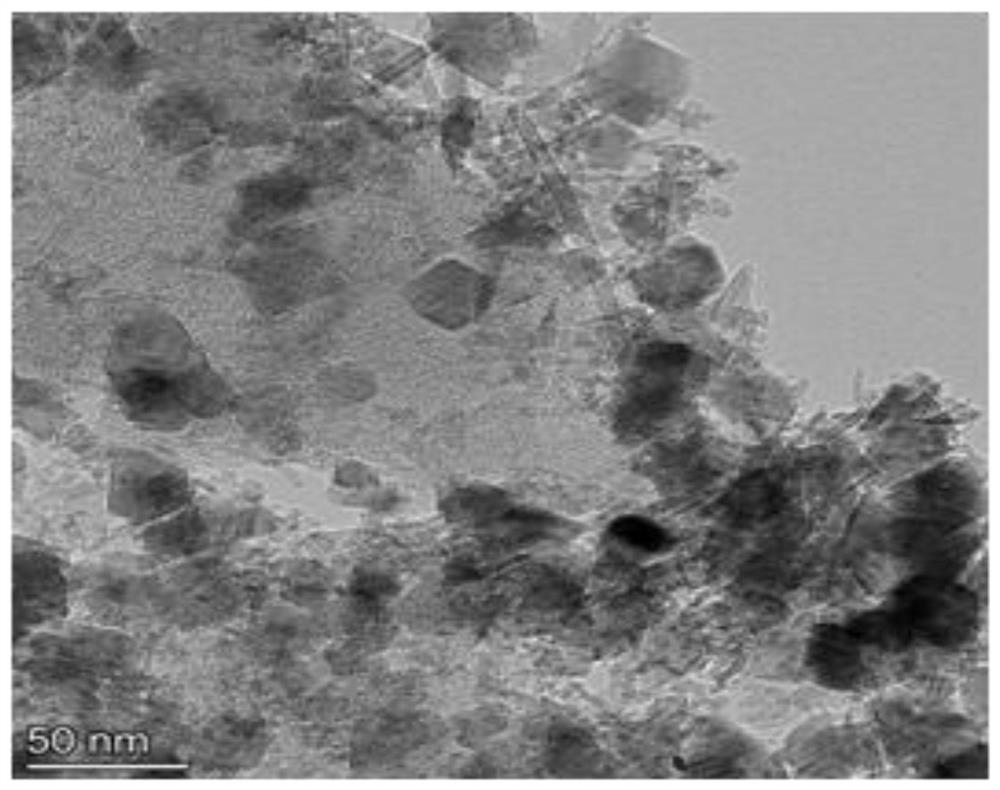

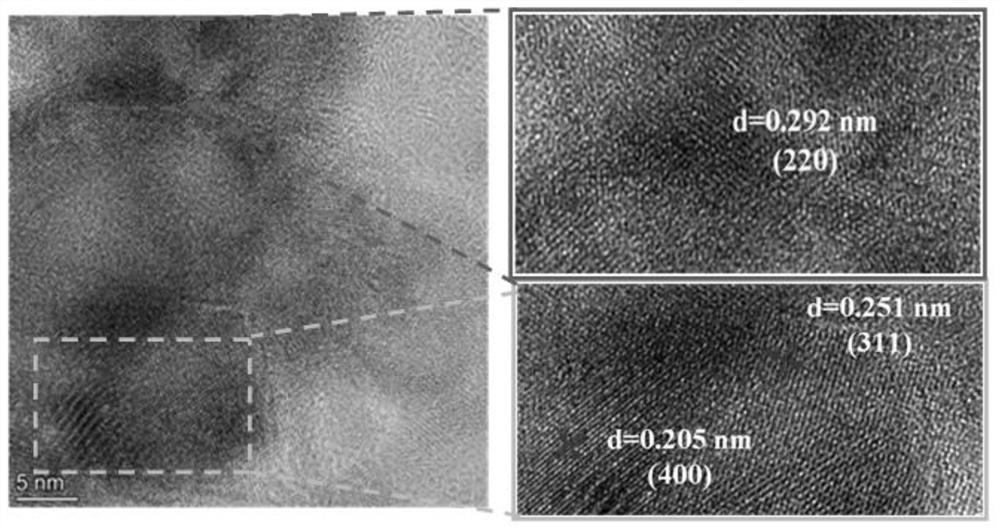

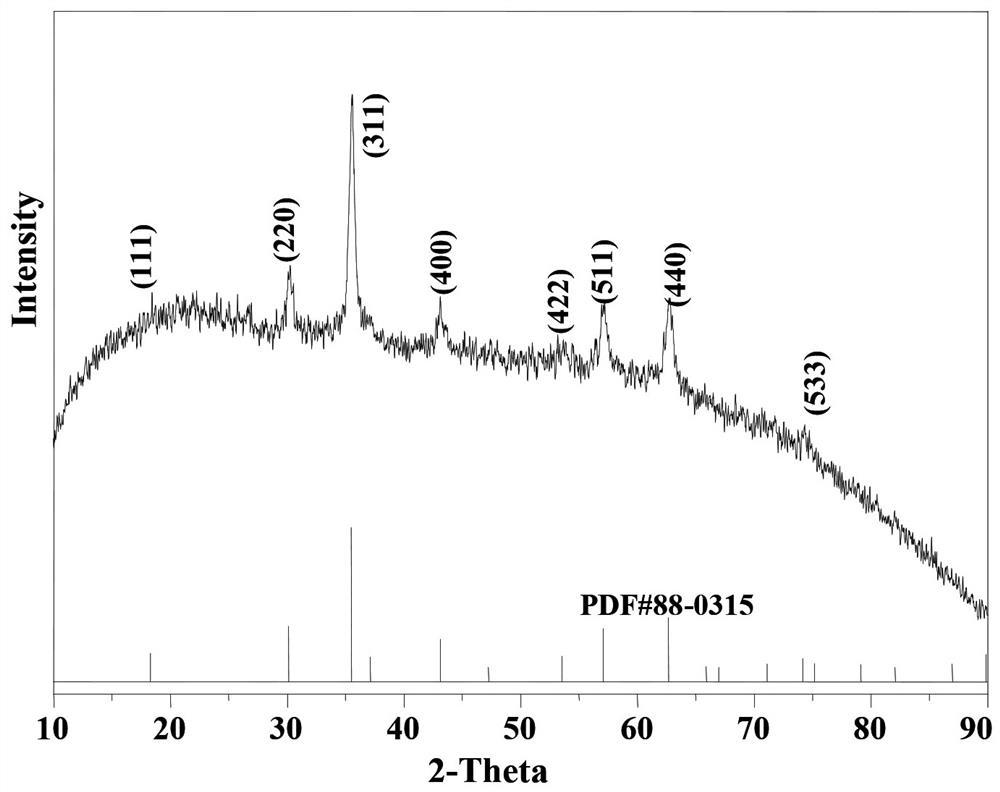

[0062] A) Preparation of ball-milled modified magnetic biochar composite Fe as a BPA-containing wastewater remover 3 O 4 @MBC;

[0063] B) Obtain a BPA-containing sewage sample, and use high performance liquid chromatography to determine the concentration of BPA in the sewage sample to be 20 mg / L;

[0064] C) The pH value of the detected sewage solution is 6.62, which is in the range of 3-9, and there is no need to adjust its pH value;

[0065] D) Add PDS to the concentration of 5 mM in the sewage sample, and then take the ball-milled modified magnetic biochar composite Fe in different proportions 3 O 4 @MBC, respectively added BPA-containing sewage samples, and reacted with shaking in the shaker for 3 h. It was found that the removal rate corresponding to different addition concentrations would change. The removal rate increased with Fe 3 O 4 @MBC varie...

Embodiment 2

[0098] see attached Figure 5 , the method for treating BPA-containing sewage and the ball-milling modified magnetic biochar composite material Fe provided by the embodiment of the present invention 3 O 4 @MBC and its preparation method are basically the same as in Example 1, except that:

[0099] A sewage sample with a BPA concentration of 20 mg / L was obtained. The pH value of the sample was 6.62. Fe was added first. 3 O 4 The concentration of @MBC was 0.5 g / L, and a certain amount of PDS was added to it to continuously change the concentration in the sample. The reaction was shaken for 3 hours in a shaker, and the two effectively removed BPA; when the concentration of PDS was 5mM , its removal process and effect are as follows Figure 5 In this example, by continuously changing the added concentration of PDS, it is found that the effective removal of BPA can be achieved when the PDS concentration is 3 mM to 9 mM, and the removal rate is greater than 91%. The optimal PDS ...

Embodiment 3

[0106] see attached Image 6 , the method for treating BPA-containing sewage and the ball-milling modified magnetic biochar composite material Fe provided by the embodiment of the present invention 3 O 4 @MBC and its preparation method are basically the same as those in Examples 1 and 2, except that:

[0107] Described step C), also comprises the following steps:

[0108] C-1) When the pH value of the measured sewage sample solution is not in the range of 3-9, add 0.1-0.5 M acid (such as acetic acid, etc.) or basic compound containing metal cations (such as NaOH, etc.) The pH of the samples was adjusted to 3-9, synergistic with Fe 3 O 4 @MBC material, catalyzes PDS, removes BPA in water.

[0109] Specifically, a sewage sample with a BPA concentration of 20 mg / L was obtained, the pH value of the sample was 11, and Fe was added. 3 O 4 The concentration of @MBC was 0.5 g / L, the concentration of PDS was 5 mM, and then the pH regulator (acid or alkali) was added to adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com