Variable multi-point unloader

An unloader, multi-point technology, applied in the conveyor control device, cleaning device, conveyor and other directions, to achieve the effect of convenient operation, simple structure and less space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

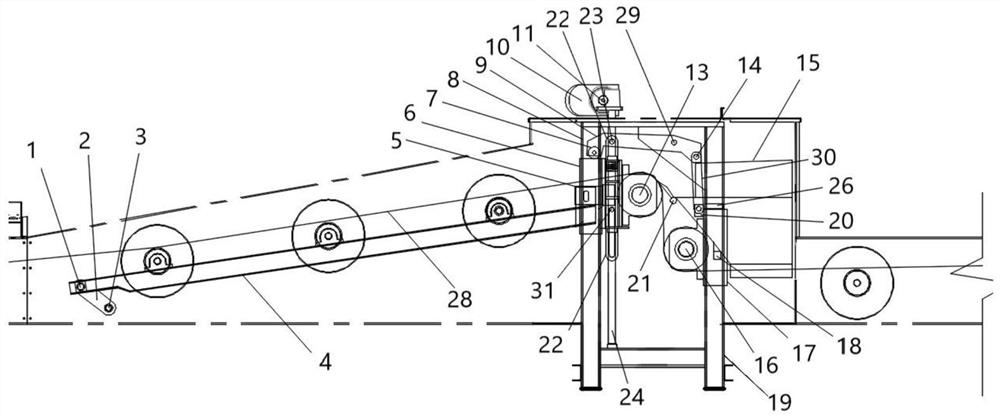

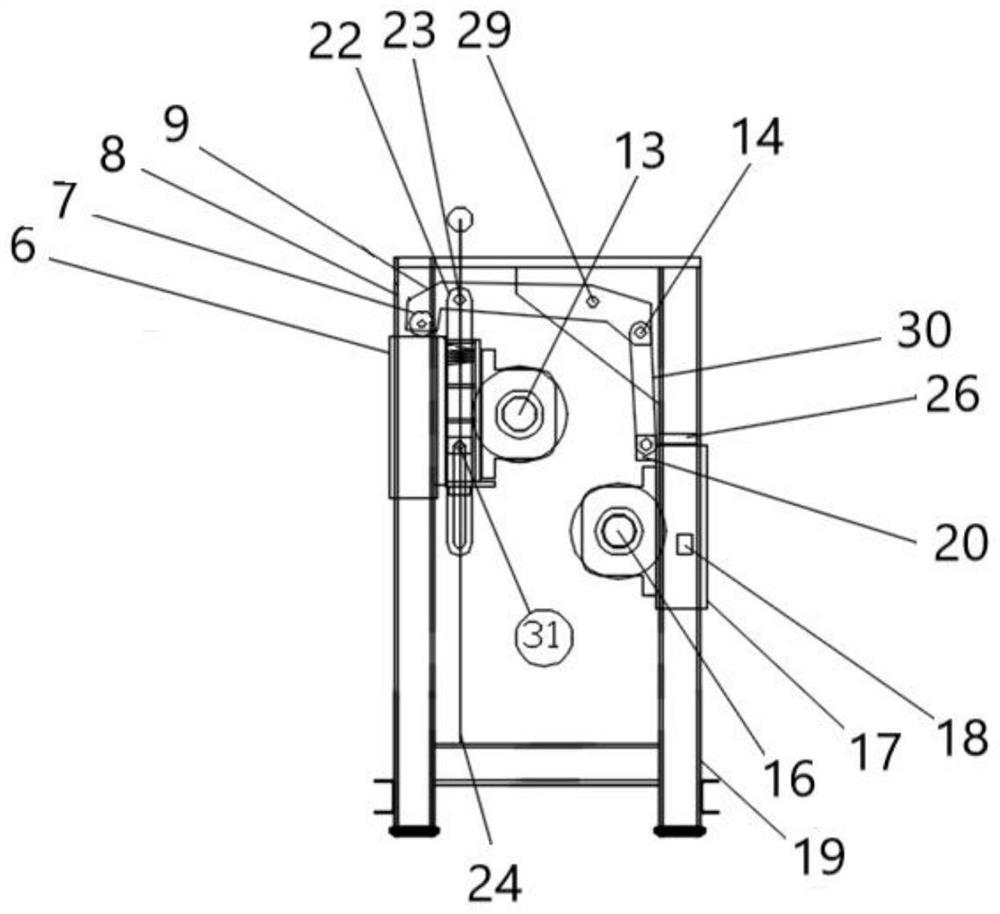

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] Such as figure 1 , figure 2 with image 3 As shown, a modified multi-point unloader of the present invention includes a row bar 4, a belt 28, a first lifting drum 13, a second lifting drum 16 and a motor 10; the belt is carried on a deep groove installed on the row bar 4 type idler, the first lifting roller 13 and the second lifting roller 16; the fixed end of the row bar 4 is connected on the frame, and the vertical lifting end of the row bar 4 is connected with the lifting lug 5 on the first sliding sleeve 6; The first lifting roller 13 is fixed on the first sliding sleeve 6; the motor 10 controls the first lifting roller 13 to rise or fall through the screw 24; the second lifting roller 16 is fixed on the second sliding sleeve 17, the second The upper end of the sliding sleeve 17 has a second lifting lug 20 connected to the lower end of the lifting link 30, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com