Multifunctional ejector rod device for pneumatically disassembling rubber rollers

A ejector device and multi-functional technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of affecting work efficiency, inconvenient operation, slow unloading speed, etc., and achieve the goal of improving work efficiency, simple structure and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

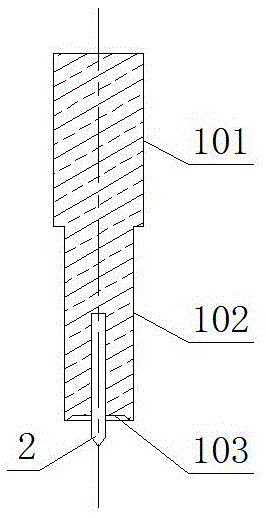

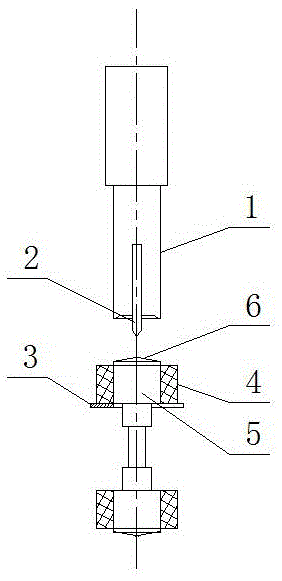

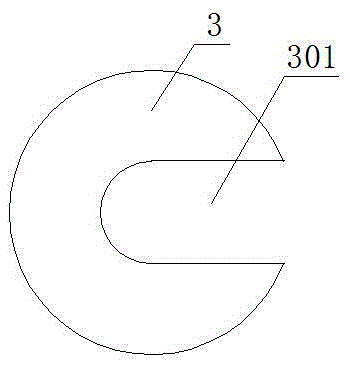

[0015] The multi-functional ejector device of the pneumatic skin removal roller includes an ejector body 1, a steel needle 2 and an extrusion gasket 3. The ejector body 1 is composed of a large-diameter rod 101 and a small-diameter rod 102; the diameter of the small-diameter rod 102 is 17.5mm, and the small-diameter rod The end of 102 is made with arc-shaped groove 103; Steel needle 2 is installed at the end axle center of small-diameter rod 102, and steel needle 2 stretches out the end 5mm of small-diameter rod 102; Side opening is shaped with socket 301, and the width of socket 301 is larger than the external diameter of top roller bearing 5 by 0.5~1mm. The diameter of the steel needle 2 is 2mm. Described rubber roller 4, extruding pad 3 and top roller bearing 5 should be on the same axis line when working. (see Figure 1-3 ).

[0016] When the multi-function ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com