Industrial waste gas secondary treatment device

A secondary treatment, industrial waste gas technology, applied in transportation and packaging, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of dust impurities remaining inside the device, reducing the treatment effect, etc., to achieve good dust filtering effect, improve filtering effect, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

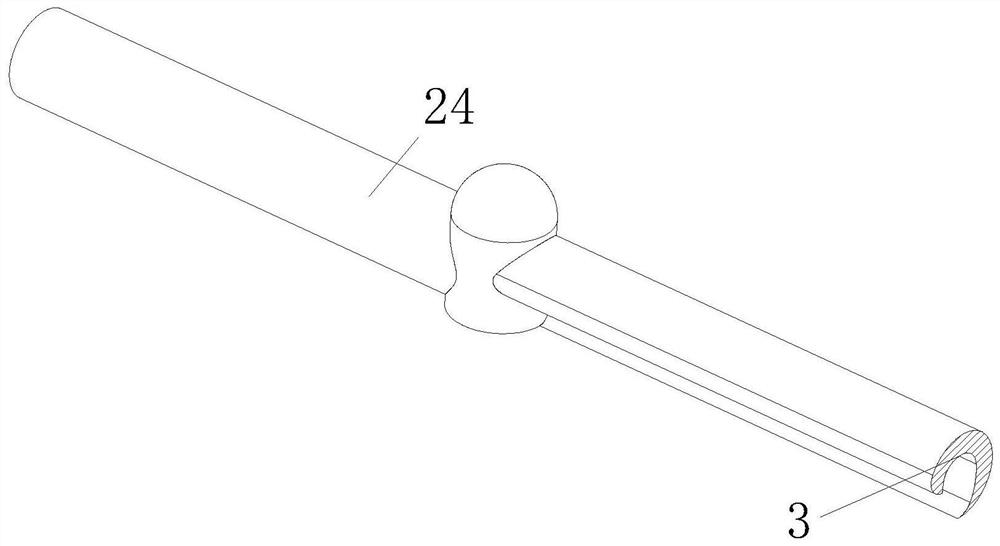

[0031] As an embodiment of the present invention, the inside of the dust removal rod 24 is provided with an arc-shaped slag removal groove 3; There is an arc-shaped slag cleaning groove 3 inside the rod 24, which can collect the dust swept away from the dust-proof net 23, so as to avoid the problem that the cleaning effect will decline after a large amount of dust adheres to the dust-removing rod 24.

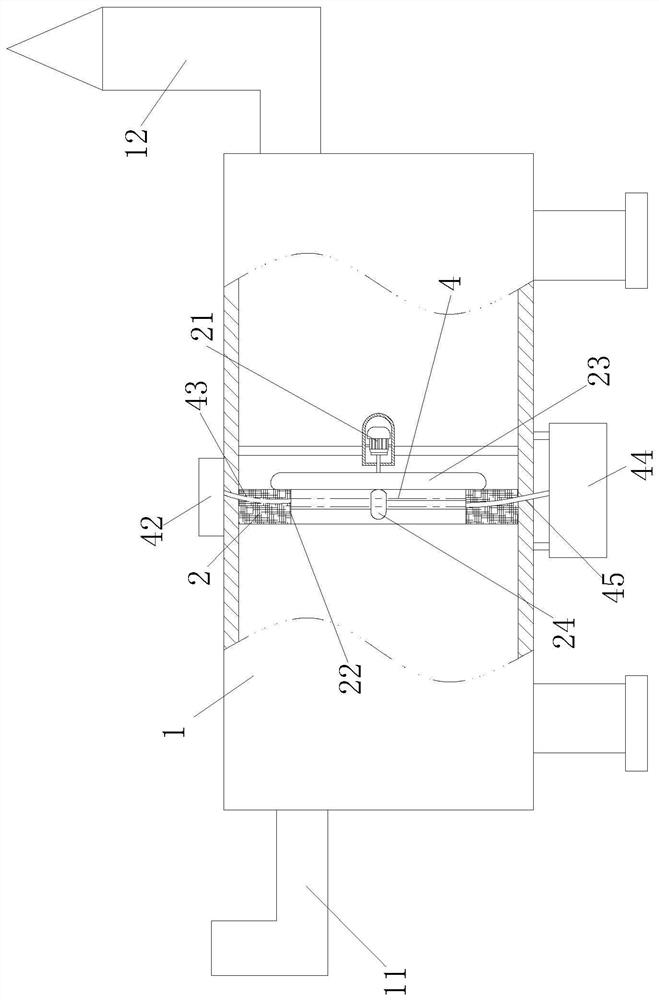

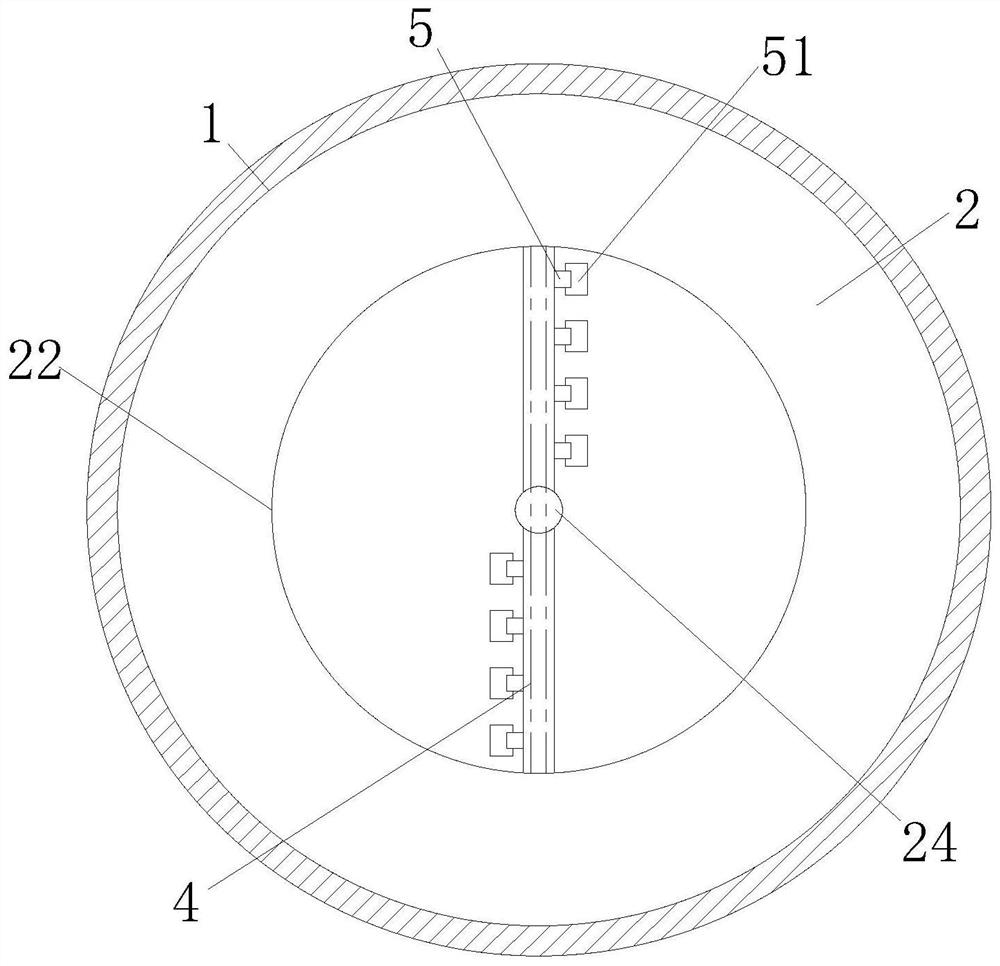

[0032] As an embodiment of the present invention, a water guide groove 4 is provided inside the dust removal rod 24; a water-permeable dust-absorbing net 41 is fixedly connected to the inner wall of the water guide groove 4; a water storage tank 42 is fixedly connected to the top of the treatment chamber 1; A first water pipe 43 is communicated between the water storage tank 42 and the top of the water guide tank 4; a water collection tank 44 is fixedly connected to the bottom of the treatment chamber 1; a second water guide pipe is communicated between the water collection tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com