Thighbone far-end inner side bone fracture plate

A bone plate and distal technology, applied in the field of medical devices, can solve the problems of iatrogenic injury, insufficient support, and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

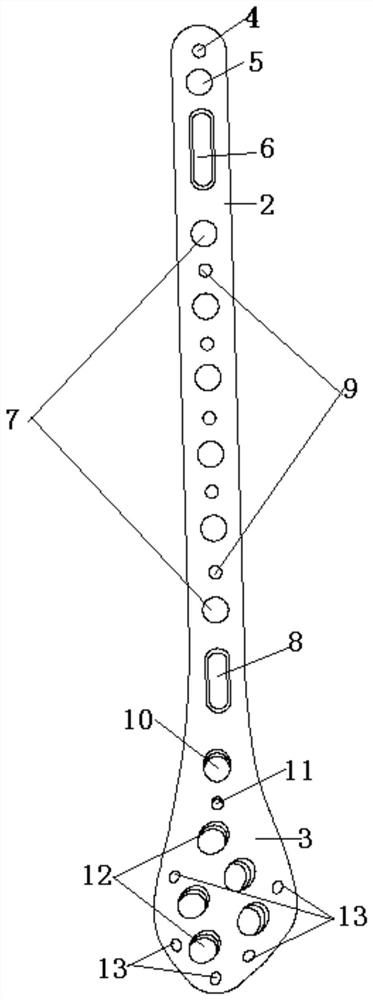

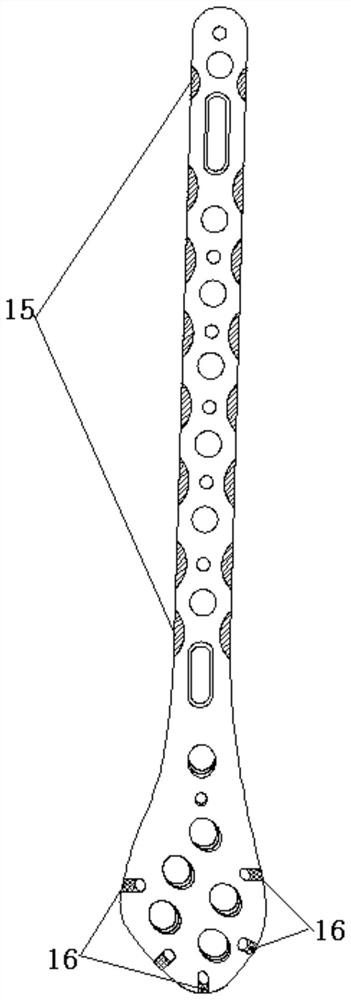

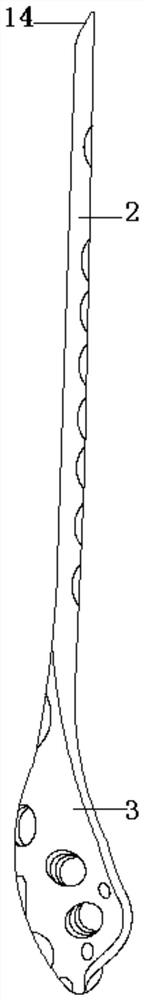

[0020] like Figure 1-Figure 3 The shown bone plate on the inner side of the distal end of the femur includes a bone plate body 1, the thickness of the bone plate body 1 is 0.4-0.6cm, the length is 9-25cm, and the width is 1.3-3.0cm. The bone plate body 1 Divided into a proximal section 2 and a distal section 3, the distal section 3 gradually thins and extends from top to bottom to both sides, bends inward, and has an arc-shaped structure, and the arc is 25° from the vertical line, which is the same as the vertical line. The contour of the lateral condyle of the distal end of the femur is fitted, and the proximal section 2 is curved to a certain arc, which is the same as the arc of the anterior femoral arch. The proximal end section 2 is provided with a proximal upper K-wire hole 4, a proximal upper locking hole 5, a sliding hole 6, a proximal lower locking hole 7 and a sliding hole I8 in sequence from top to bottom. The proximal lower locking hole 7 There are a plurality of ...

Embodiment 2

[0022] like Figure 1-Figure 3 The shown bone plate on the inner side of the distal end of the femur includes a bone plate body 1, the thickness of the bone plate body 1 is 0.4-0.6cm, the length is 9-25cm, and the width is 1.3-3.0cm. The bone plate body 1 Divided into a proximal section 2 and a distal section 3, the distal section 3 gradually thins and extends from top to bottom to both sides, from 4-6mm to 3.0mm at the most distal end, and bends inward in an arc. The radian is 25° from the vertical line, and fits with the contour of the outer condyle of the distal femur. The proximal section 2 is curved to a certain radian, which is the same as the radian of the anterior arch of the femur, which is convenient for the bone plate body 1 to fit. The proximal end section 2 and the distal end section 3 are connected smoothly and in an integrated structure. The proximal end section 2 has a proximal upper K-wire hole 4, a proximal upper locking hole 5, and a sliding hole 6 in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com