A temperature and humidity control system and control method for live working tool room

A technology of humidity control system and live work, which is applied in the direction of control/regulation system, comprehensive factory control, non-electric variable control, etc. It can solve problems such as condensation, achieve the effects of ensuring safety, avoiding the risk of condensation, and reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

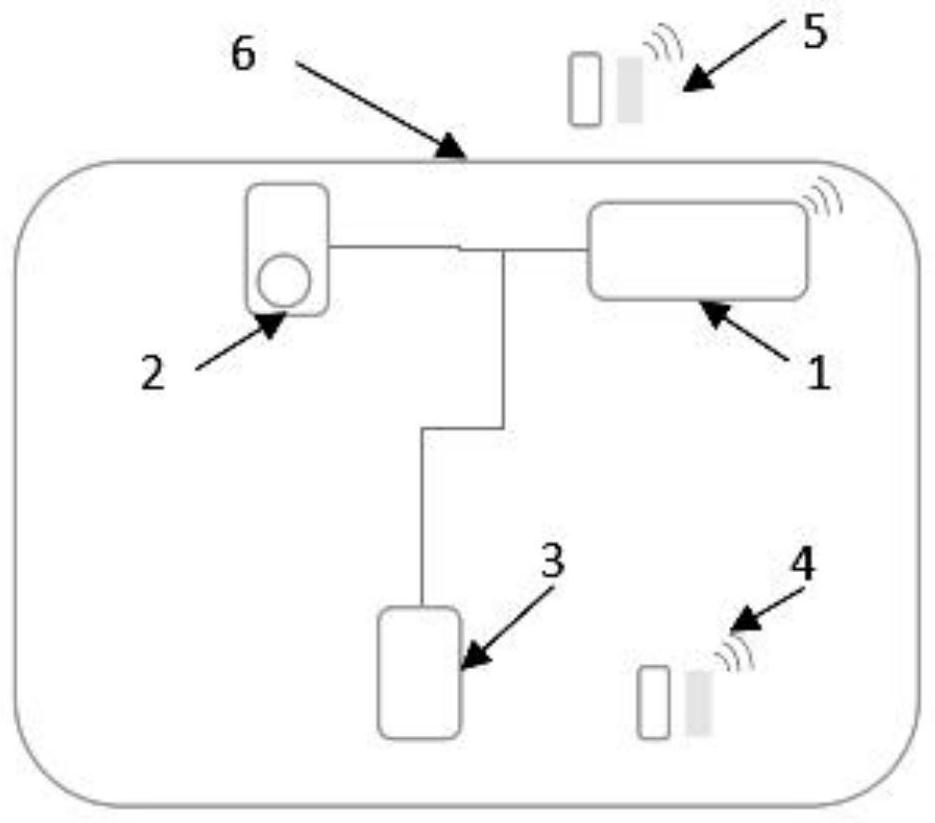

[0037] Example 1: Such as Figure 1 and 3 As shown, a live working tool room temperature and humidity control system, comprising controller 1, temperature regulation equipment 2, dehumidification equipment 3, indoor temperature and humidity sensor 4, outdoor temperature and humidity sensor 5, tool warehouse 6, controller 1 and temperature regulation equipment 2, dehumidification equipment 3, indoor temperature and humidity sensor 4 and outdoor temperature and humidity sensor 5 connected, temperature regulation equipment 2, dehumidification equipment 3, indoor temperature and humidity sensor 4 is installed in the tool storeroom 6.

[0038] Preferably, the above-described indoor temperature and humidity sensor 4, outdoor temperature and humidity sensor 5 thereof and the controller 1 of the data transmission is a wireless transmission mode or cable data transmission mode, the wireless transmission mode using LoRa module, WiFi module, RF module or Bluetooth module.

[0039] Preferably,...

Embodiment 2

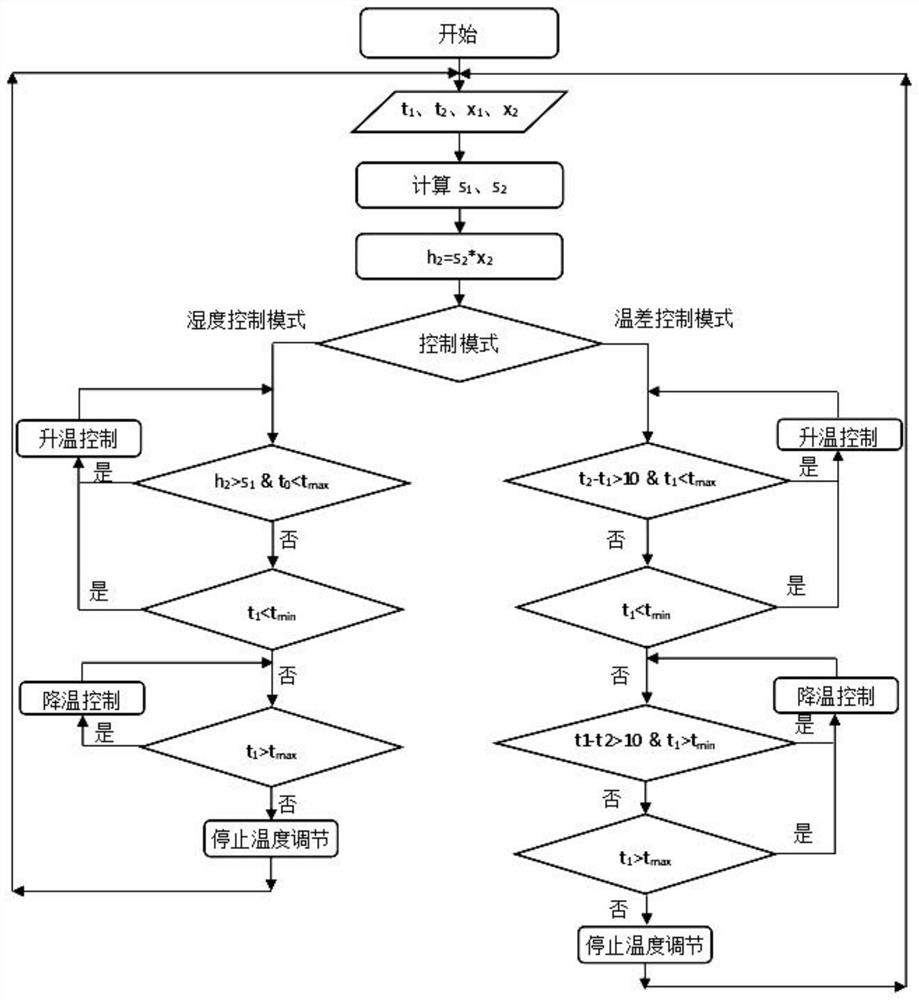

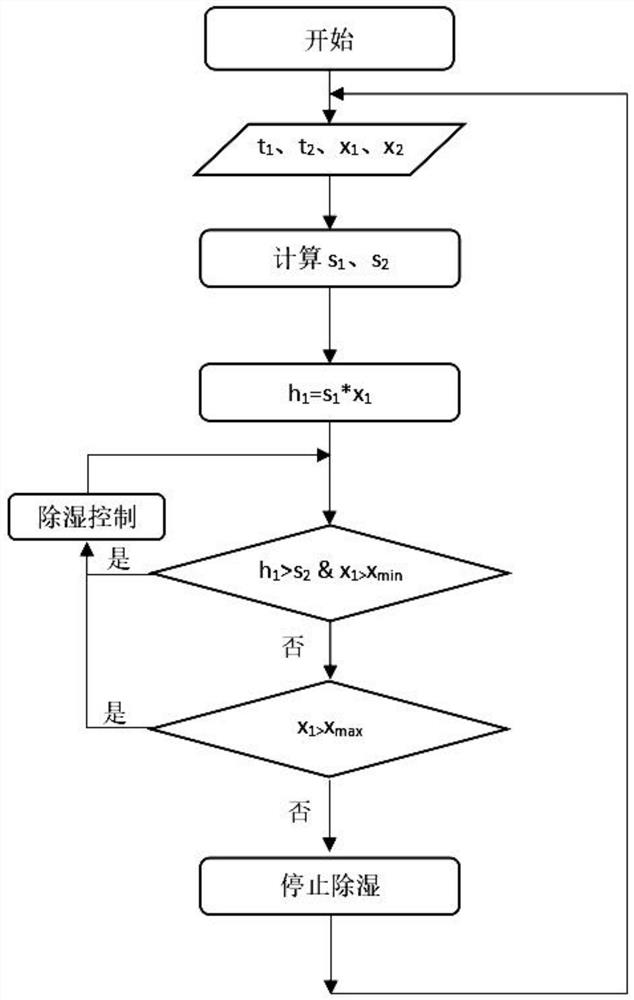

[0044] Example 2: A live working tool room temperature and humidity control system control method, the method comprising a temperature control method and a humidity control method.

[0045] The temperature control method comprises the following steps:

[0046] Step 1: Indoor temperature and humidity sensor 4, outdoor temperature and humidity sensor 5 will collect the temperature and humidity data in real time to the controller 1, controller 1 real-time acquisition of indoor temperature and humidity sensor 4, outdoor temperature and humidity sensor 5 to send the data;

[0047] Step 2: Controller 1 passes through t 1 、t 2 Calculate s 1 、s 2 。 where t 1 for the room temperature, t 2 for the outdoor temperature, s 1 for t 1 Absolute saturated humidity corresponding to temperature, s 2 for t 2 Absolute saturated humidity corresponding to temperature;

[0048] Step 3: Calculate the outdoor absolute humidity h 2 ,h 2 =s 2 *x 2 。 where x 2 Relative humidity measured for outdoor temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com