Self-service water adding system

A technology of adding water pipes and water tanks, which is applied in the field of automation equipment, can solve problems such as reducing labor costs, cross-flow of sewage at water filling stations, and high sealing in high-speed service areas, achieving the effect of accelerating promotion and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

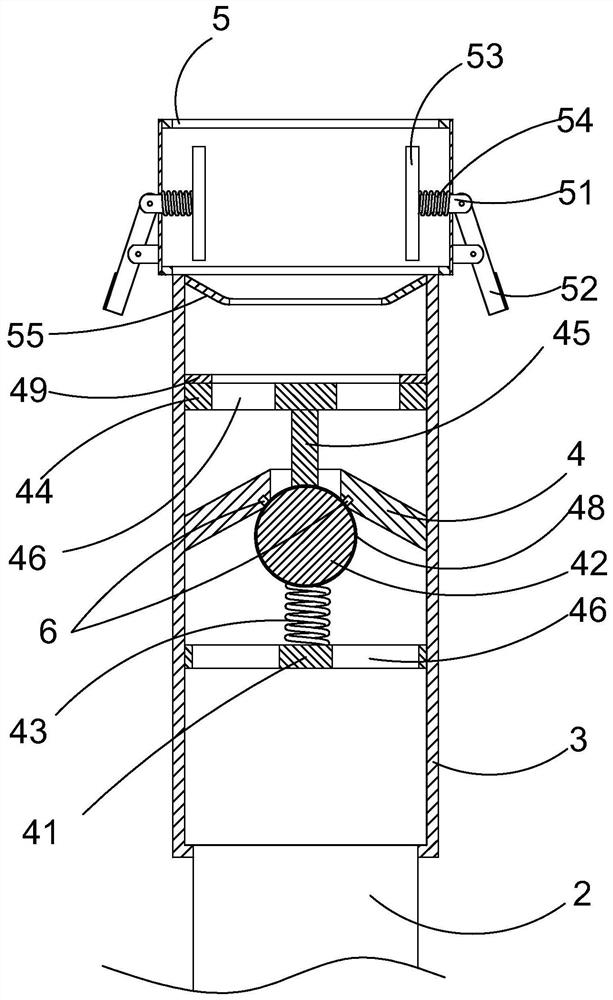

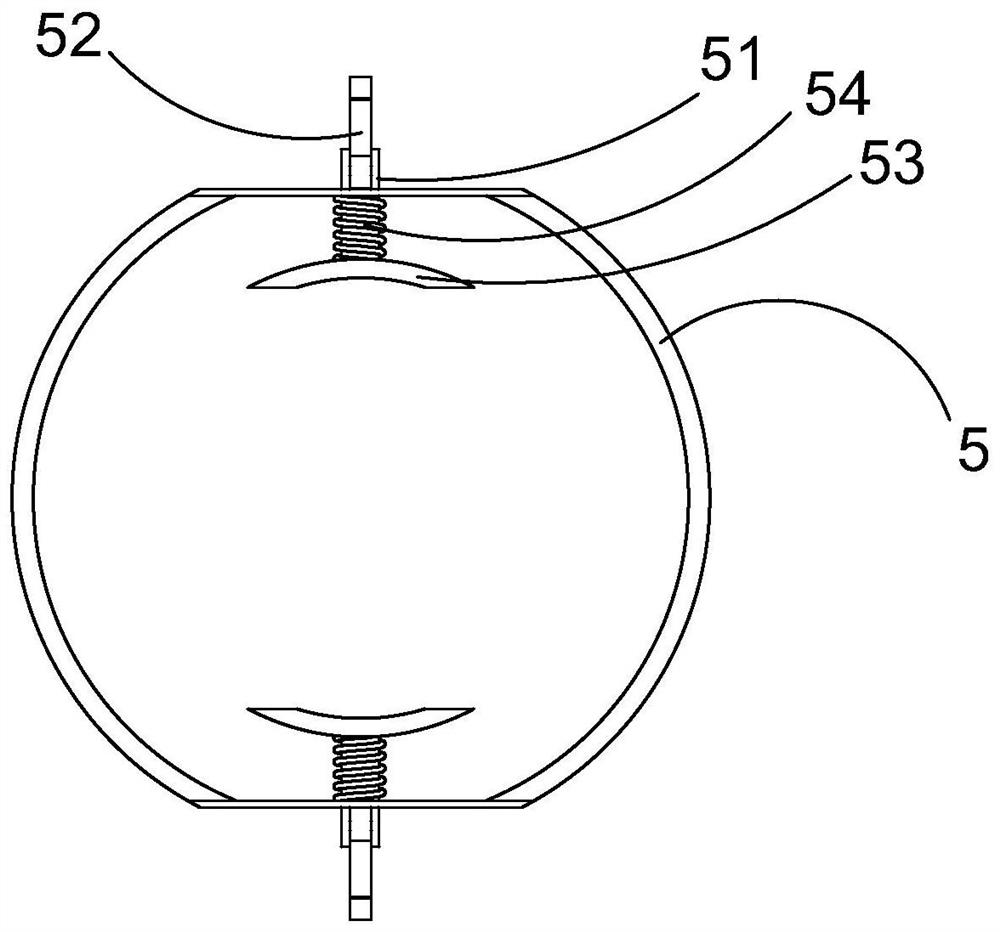

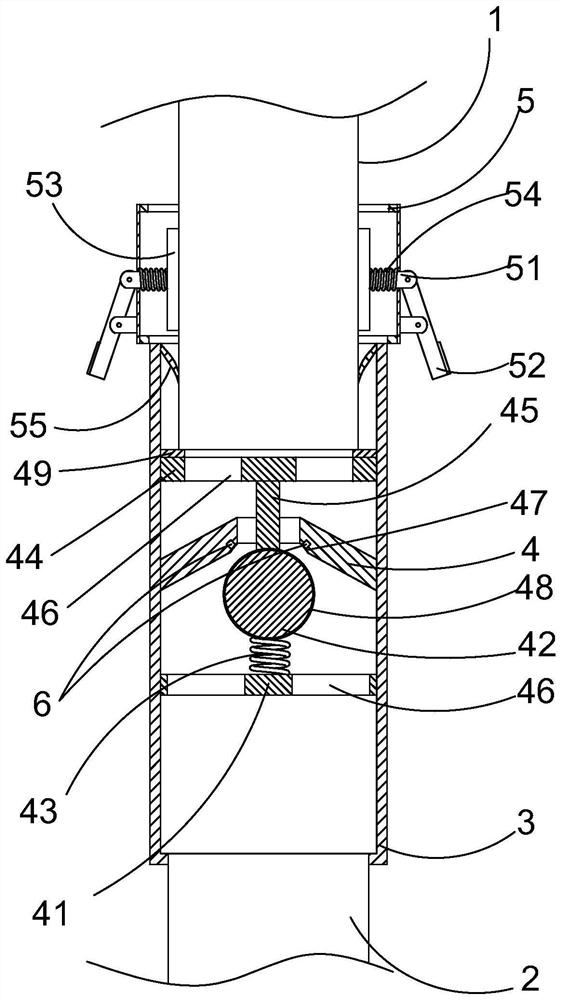

[0031] refer to Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a self-service water filling system, including a water gun with one end connected to the water inlet pipe 1 of the external truck water tank and the other end connected to the external water pipe 2. The water inlet pipe 1 connects the other end to the hollow gun body 3 connected to the external water supply pipe 2, the valve seat 4 arranged on the inner wall of the gun body 3, and the fixed valve seat 4 arranged on the inner wall of the gun body 3 close to the other end of the gun body 3. Plate 41, set on the fixed plate 41 for sealing the valve flap 42 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com