Rapid well abandoning device for deepwater high-pressure gas well

A high-pressure, gas well technology, applied to wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of long solidification time, high platform use cost, cost increase, etc., and speed up well abandonment Efficiency, saving of working time, effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

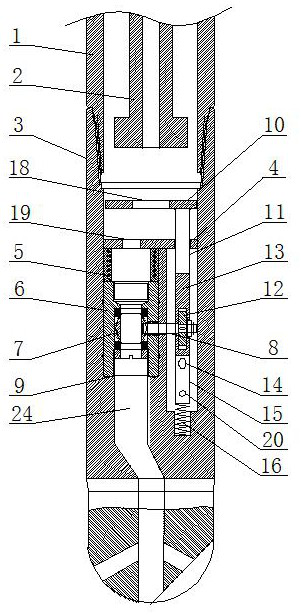

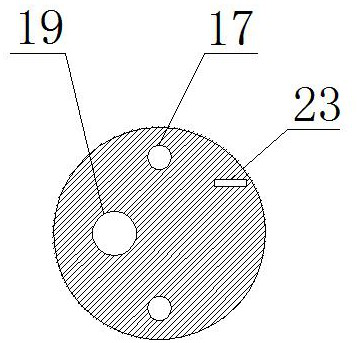

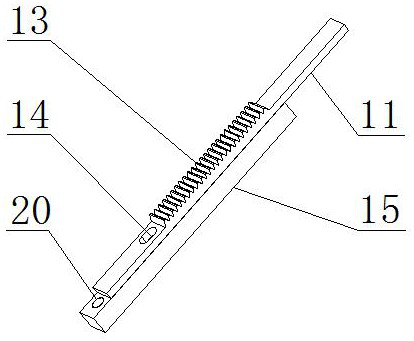

[0022] The deep-water high-pressure gas well rapid abandonment device is composed of an upper casing 1, a lower casing 3, a drill pipe 2, a flange plate 4, a ball valve mechanism and a sliding mechanism. Hollow body with diameter, the center hole 24 of the lower casing 3 is provided with a limited boss 9, the lower casing 3 on the side of the center hole 24 is axially opened with a groove, and the bottom of the groove is fixedly installed with a shock absorbing spring 16, A flange plate 4 is fixedly installed in the lower casing 3, and a ball valve mechanism is set in the center hole 24 of the lower casing 3 on one side of the flange plate 4. The ball valve mechanism consists of a ball valve 7, a sleeve 5, an assembly seat 6, and a transmission shaft 8. Composed of the gear 12, the bushing is set in the center hole 24 of the lower bushing 3, the upper end of the bushing is in conflict with the flange plate 4, one side of the mounting seat 6 is in conflict with the bushing, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com