A light rod magnetic sealing structure device

A technology of magnetic sealing and polished rods, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of not being able to guarantee the reliability of dynamic sealing of sealing materials, easy wear of sealing materials, and failure of sealing structures, etc. Achieve a good dynamic sealing effect, improve the overall sealing performance, and increase the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below, so that those skilled in the art can implement it with reference to the description.

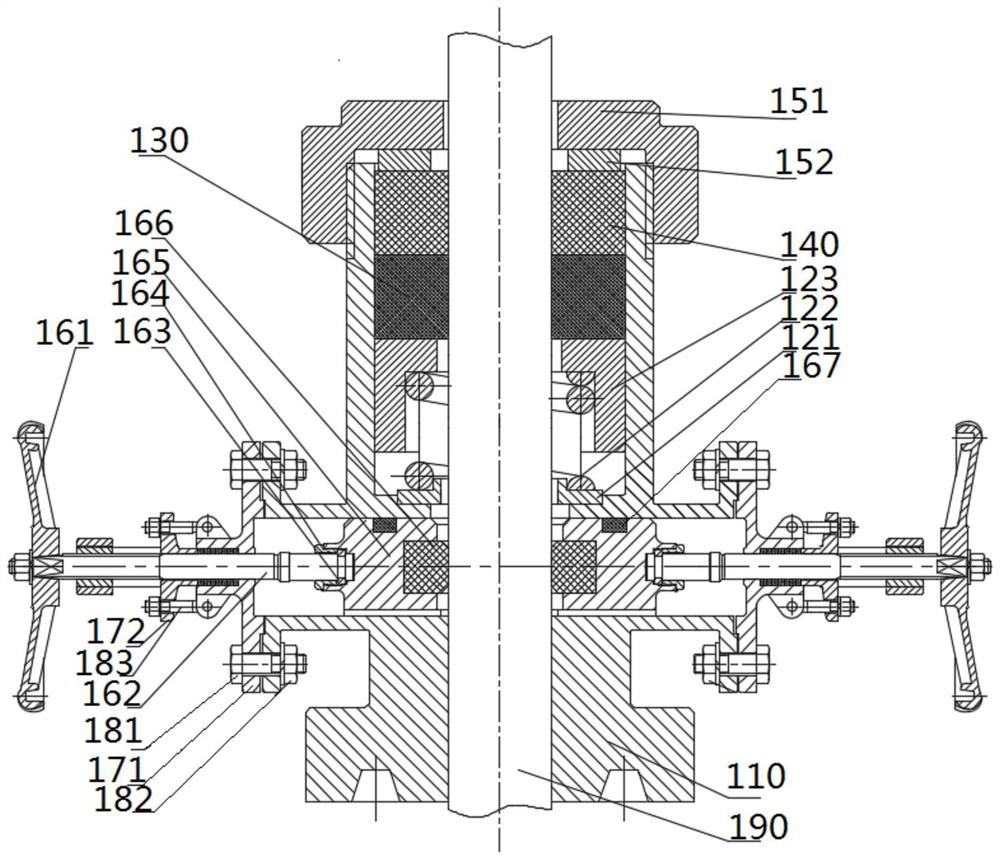

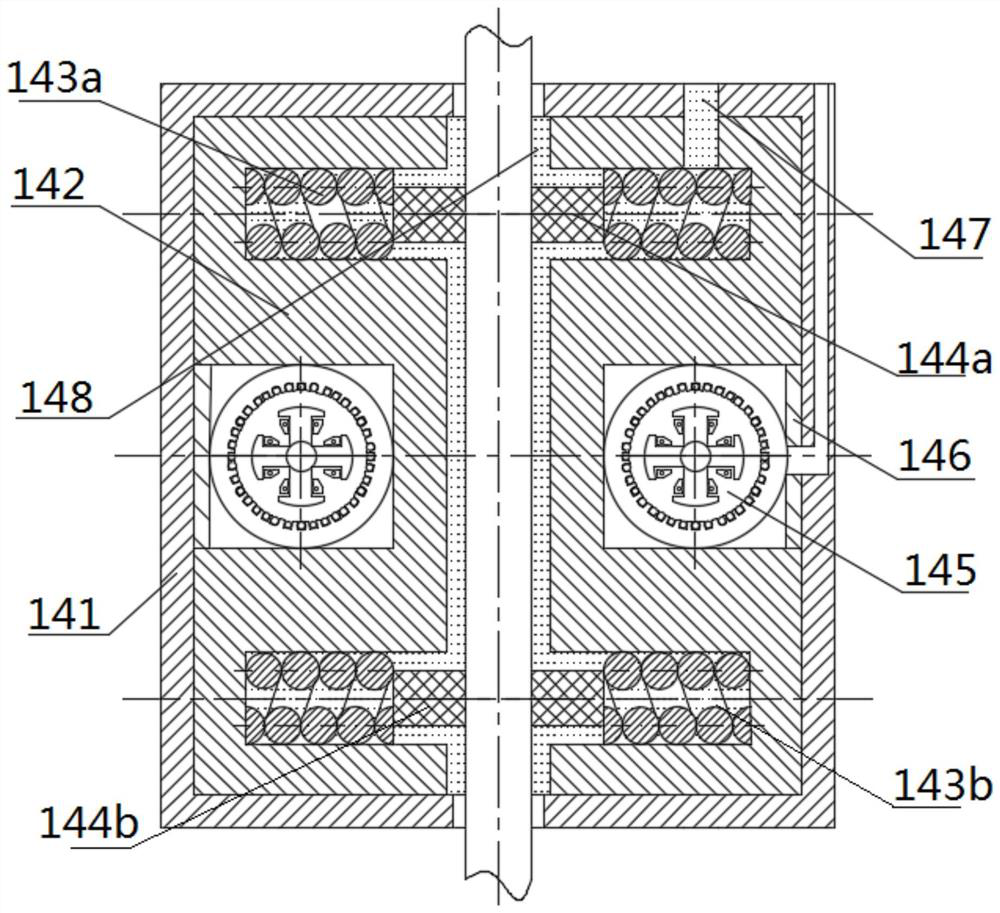

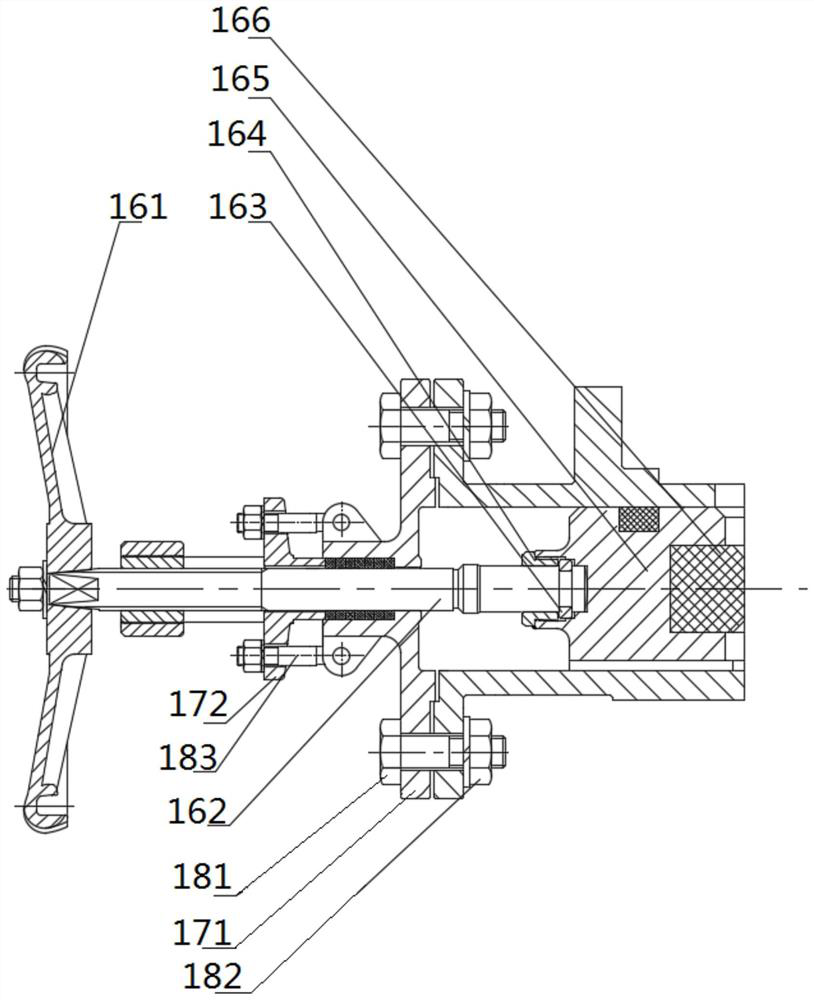

[0059] like figure 1As shown in the figure, the present invention provides a polished rod magnetic sealing structure device. The magnetic sealing device 140 and the compensation compression spring 122 are arranged coaxially from top to bottom. On both sides of the lower side, the first casing 110 is connected to the wellhead tee through the flange, and specifically includes: the first casing 110, the spring seat 121, the compression spring 122, the top sleeve 123, the sealing packing 130, the magnetic seal A device 140, a sealing end, two blowout preventers and a polished rod 190. One end of the first casing 110 is detachably disposed on the wellhead and is coaxially sleeved on the outside of the polished rod 190. The first casing 110 is under the The wellhead tee is connected by flange bolts; the first housing 110 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com