Water conservancy project environment-friendly reservoir

A technology for water conservancy projects and reservoirs, which is applied in water/sewage treatment, water/sludge/sewage treatment, water supply devices, etc., which can solve the problem that garbage cannot be processed in time, affect the normal circulation of reservoirs, and affect water conservancy projects. Problems such as normal work, to achieve the effect of smooth rising water flow, ensuring normal flow and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

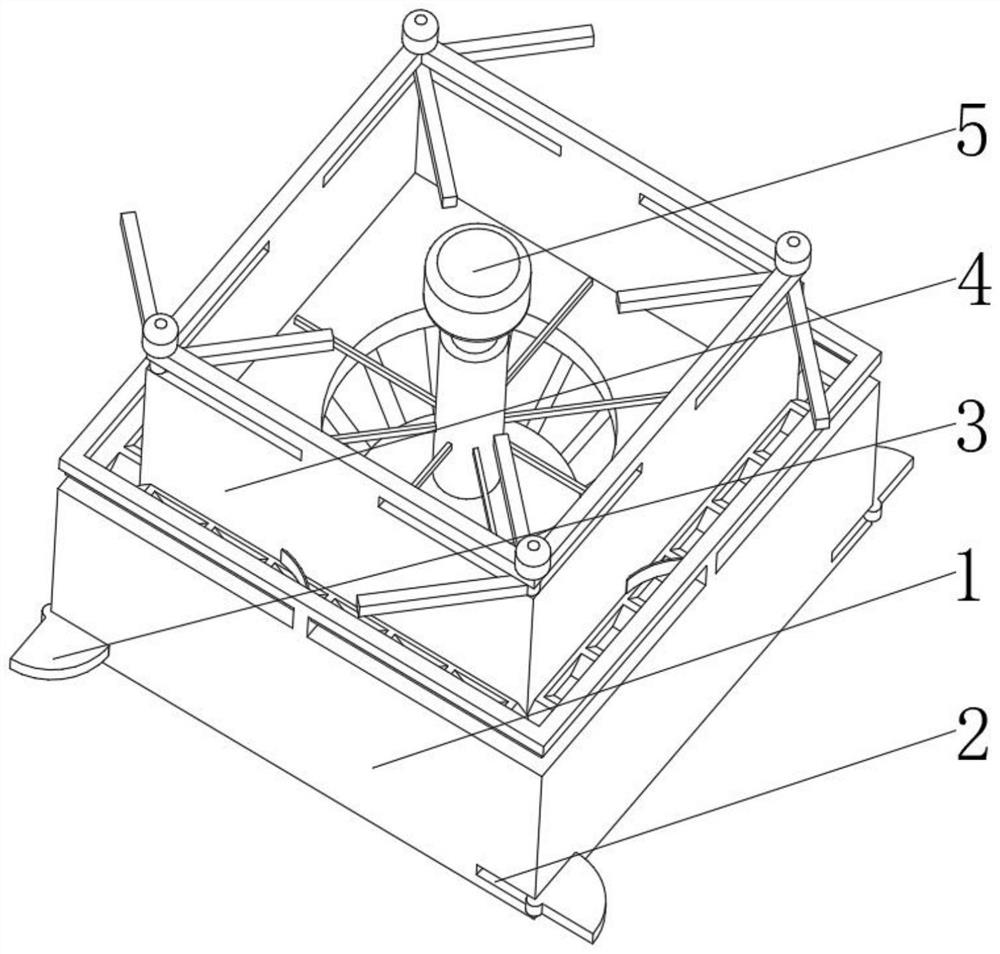

[0042] see figure 1 , 2 , 5, the present invention provides a kind of technical scheme: a kind of water conservancy project environmental protection reservoir, specifically comprises:

[0043] Bottom pool 1, the bottom pool 1 has a square pool body, and a discharge port 2 provided at the four corners of the square pool body, and a plug 3 arranged in the inner cavity of the discharge port 2; through the design of the arc surface of the plug 3 itself, the water The pressure of the hydraulic pressure is dispersed to avoid the overload of the component's own water pressure, protect the component and prolong the service life;

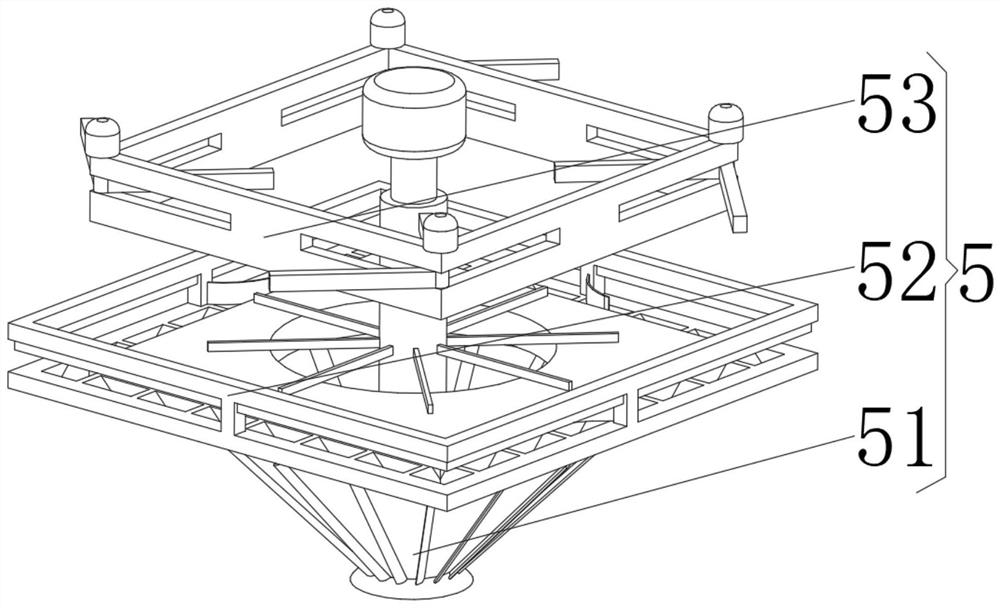

[0044] Top pool 4, the top pool 4 has a square pool frame, and a water storage auxiliary mechanism 5 installed on the top and bottom of the square pool frame, the water storage auxiliary mechanism 5 includes:

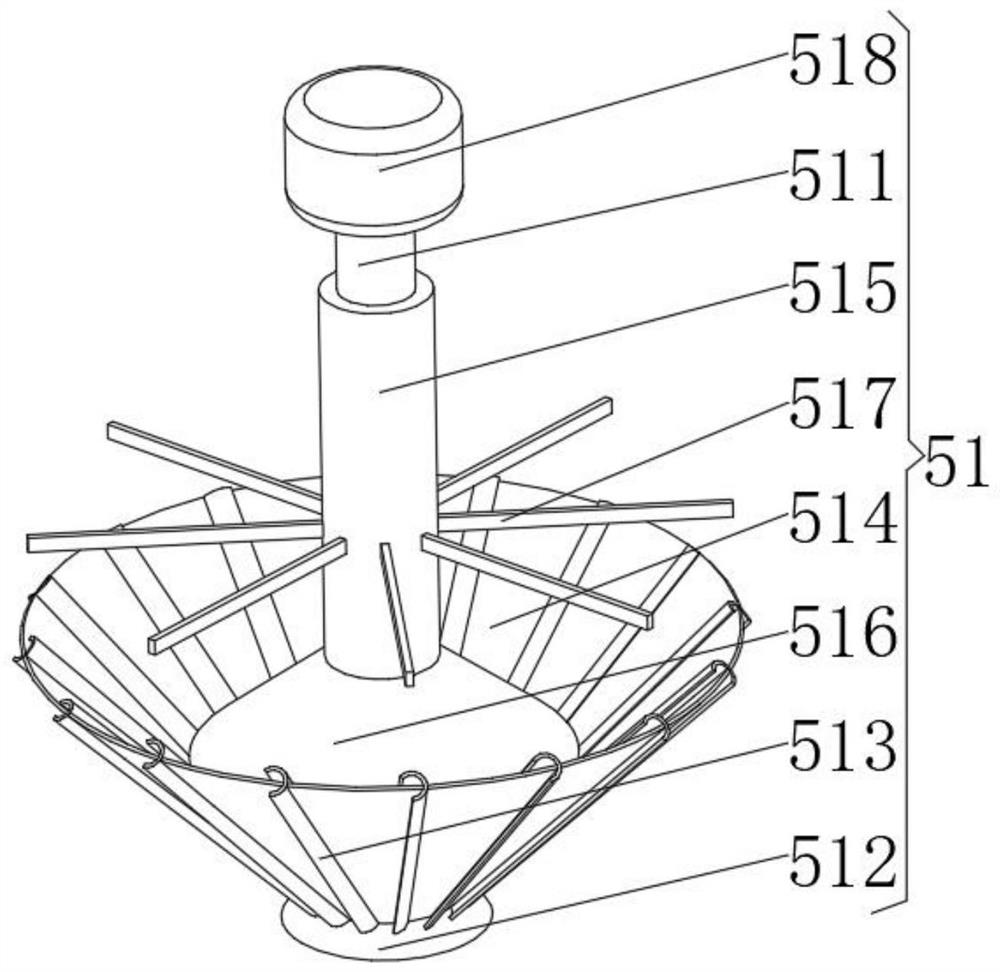

[0045] Inner diversion cleaning mechanism 51, the inner diversion cleaning mechanism 51 has an umbrella-shaped main body, a debris cleaning mechani...

Embodiment 2

[0052] see Figure 1-3 , 5. On the basis of Embodiment 1, the present invention provides a technical solution: the internal diversion cleaning mechanism 51 includes:

[0053] Positioning column 511, the positioning column 511 has a columnar body, and a spherical seat 512 installed on the bottom of the outer surface of the columnar body, and a guide curved bar 513 arranged on the top of the spherical seat 512, and a guide bar 513 fixed at the middle position of the guide bar 513 Auxiliary umbrella surface 514; the interior of the bottom pool 1 can be cleaned and driven by the setting of the deflector curved rod 513. At the same time, it can cooperate with the auxiliary umbrella surface 514 to drive the internal water flow countercurrently, so as to facilitate the suspension in the The sundries in the reservoir are floated up against the current to clean the reservoir more thoroughly.

[0054] Drive sleeve 515, the drive sleeve 515 has a cylindrical main body, and a folding sup...

Embodiment 3

[0059] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the debris cleaning mechanism 52 includes:

[0060] Partition plate 521, the partition plate 521 includes a square plate body, and a through hole 522 in the middle of the square plate body, and a filter hole 523 located on the outer wall of the through hole 522 in the square plate; the cleaning rod 517 is in contact with the partition plate 521 The friction generated vibrates the partition plate 521, which promotes the surface of the partition plate 521 through the vibration, and accelerates the separation of moisture contained in the sundries. At the same time, the vibration undulates the sundries to prevent the sundries from blocking and affecting the subsequent continuous price.

[0061] Track plate 524, this track plate 524 comprises square ring body, and the guide rail 525 that is installed on the bottom of square ring body, and the mover 526 that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com