Buoy device, method for controlling buoy to fall down in time, water inlet valve and water drainage valve

A water inlet valve and floating control technology, applied in the field of sanitary ware, can solve the problems of buoyancy setting, the displacement exceeding the actual requirement, and the parts cannot move in time, etc., and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

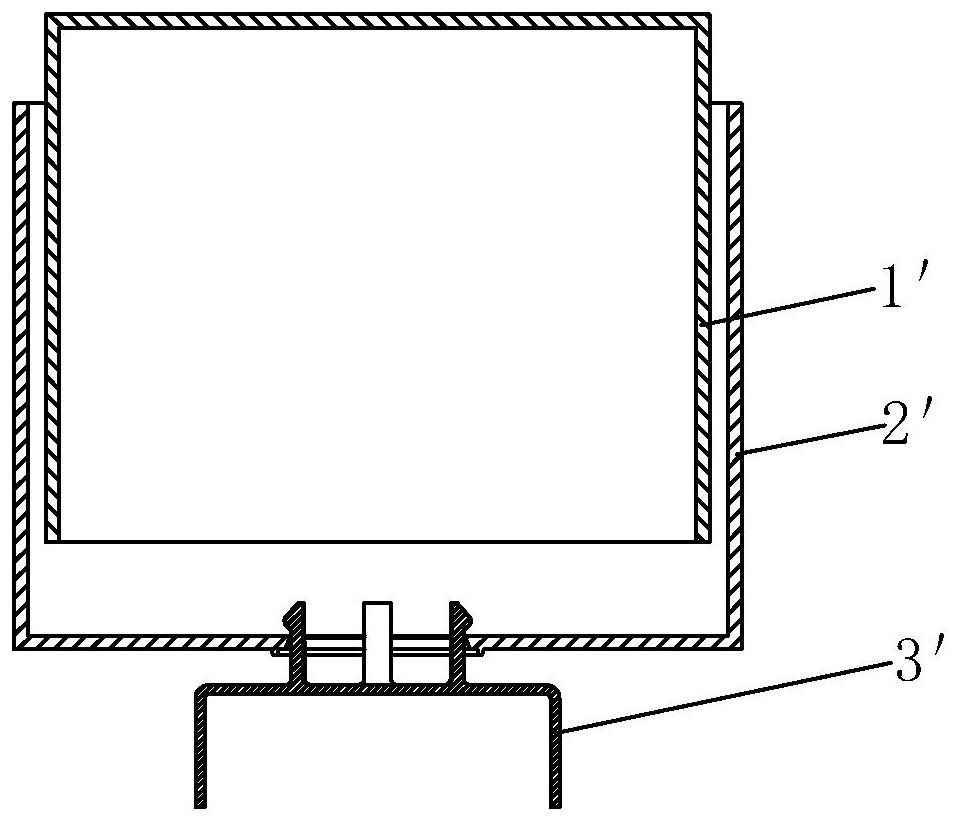

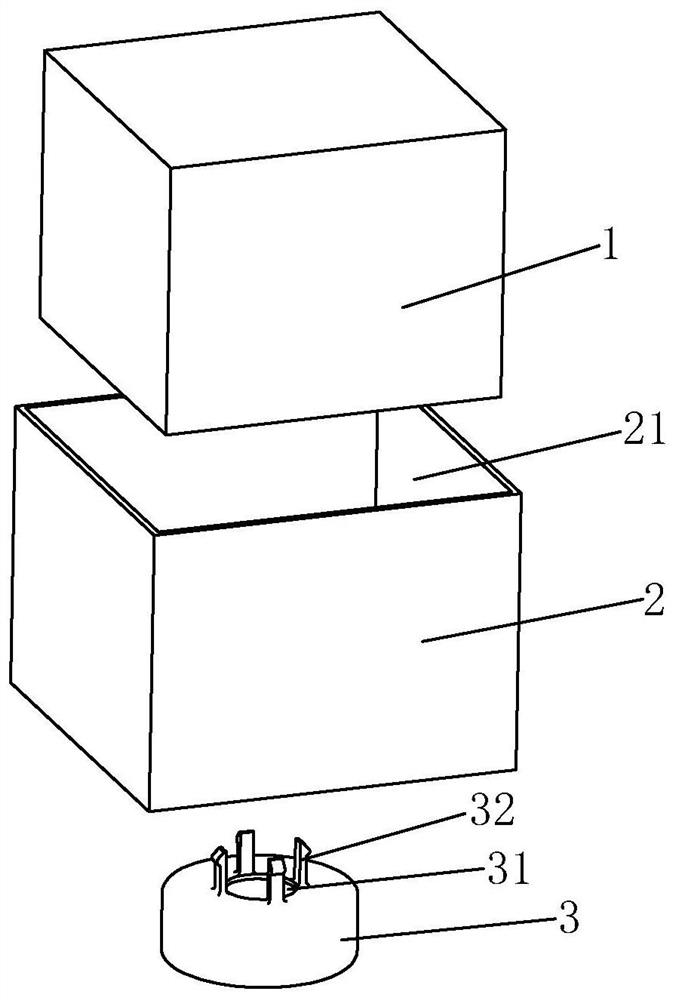

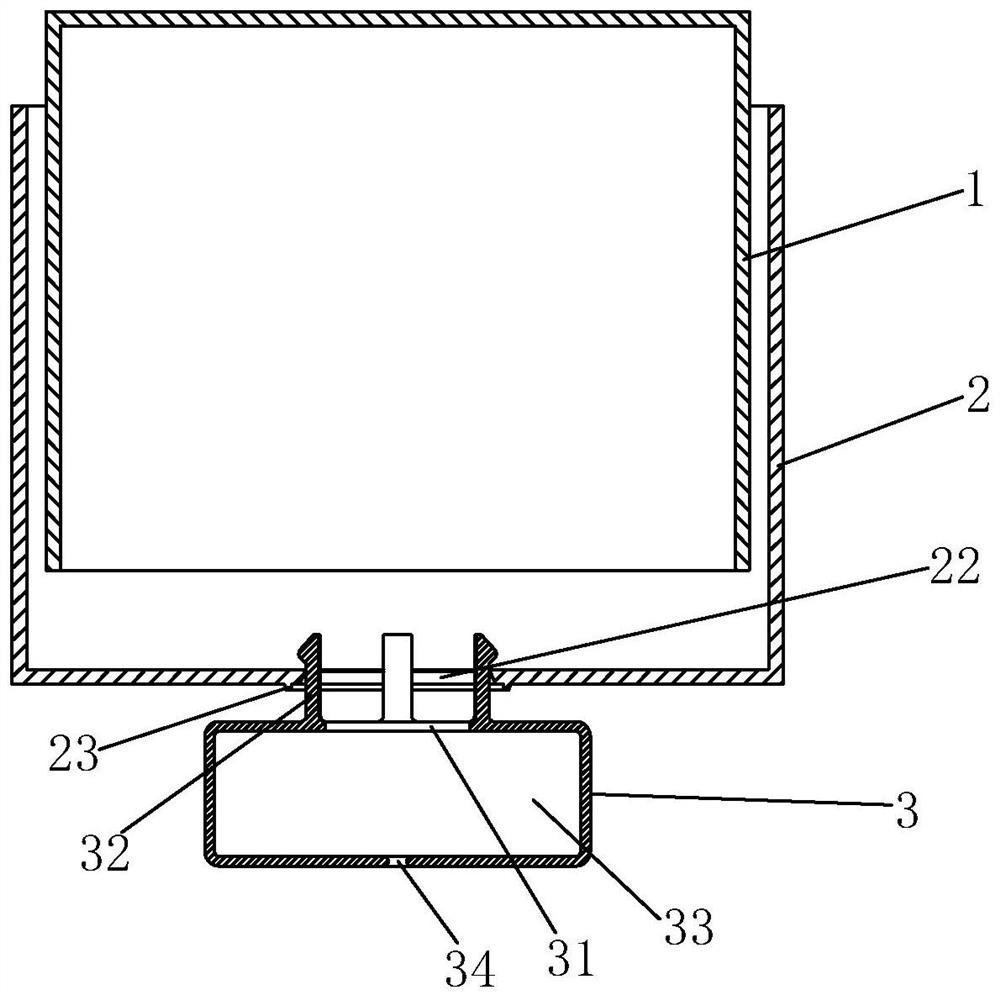

[0030] Examples, see Figure 2-Figure 8 As shown, a buoy device of the present invention is applied to a water tank, especially a toilet tank, and includes a buoy seat 2, a one-way switch 3 and a buoy 1 which is located in the buoy seat 2 and can be floated by buoyancy. 2 The upper end is provided with an opening 21 to prevent the water in the buoy 1 and the water supply tank from entering the buoy seat 2; the lower end of the buoy seat 2 is provided with a drain port 22, and the one-way switch 3 is movable at the drain port 22. And when this one-way switch 3 floats up to put in place, close this drain port 22; Drainage structure for drainage; after the buoy seat 2 is filled with water, the buoy 1 is subjected to the buoyancy effect (if the buoy is not subjected to the external force that limits its floating, the buoy can float), and a part of the water in the buoy seat 2 is released from the buoyancy. The water inlet structure enters the water storage chamber 33, fills the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com