Quick positioning device for detecting hollow pile through low strain method

A technology of positioning device and low-strain method, which is applied in the field of detection and can solve problems such as large position errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

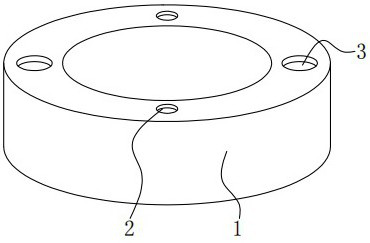

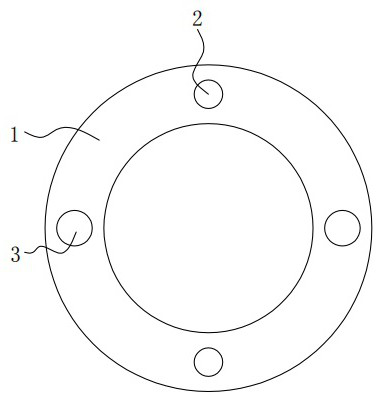

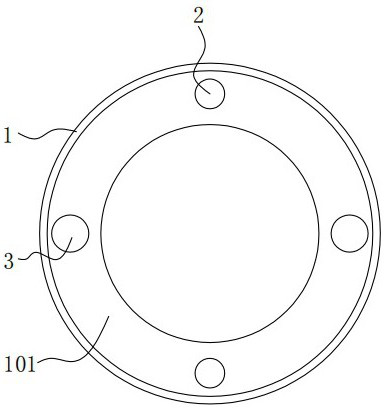

[0022] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the low strain method detection hollow pile quick positioning device provided by the present invention; figure 2 for figure 1 The top view of the whole shown; image 3 for figure 1 Bottom view of the whole shown.

[0023] A rapid positioning device for detecting hollow piles by a low-strain method includes: a positioning column 1, and a casing hole 101 is opened at the bottom of the positioning column 1;

[0024] At least two sets of sensor installation points 2, at least two sets of sensor installation points 2 are set on the top of the positioning column 1;

[0025] There are at least two groups of vibration-hammering application points 3 , and at least two groups of vibration-hammering application points 3 are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com