Suspension type freight turnout steel rail follow-up rail locking device and working process thereof

A suspension type, rail locking technology, applied in the direction of roads, tracks, buildings, etc., can solve the problems of difficult processing and heat treatment, low shape accuracy, low precision, etc., and achieve accurate rail locking, stable train operation and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

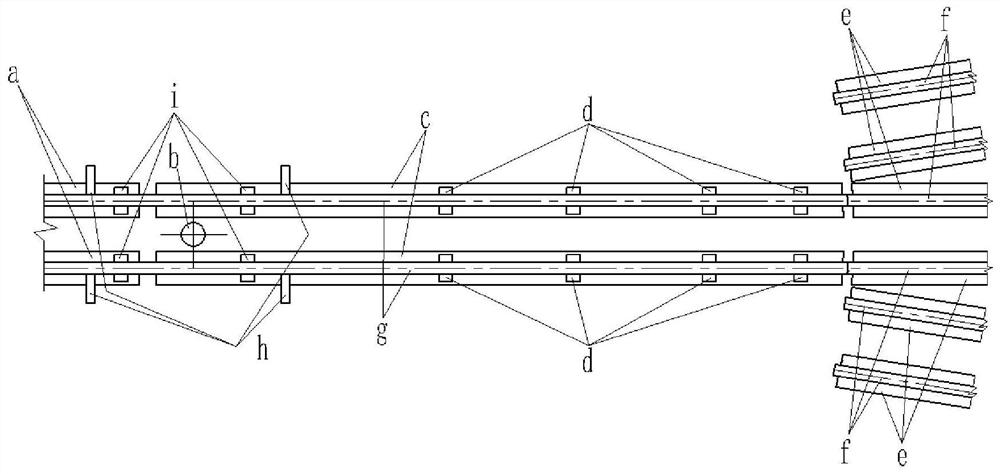

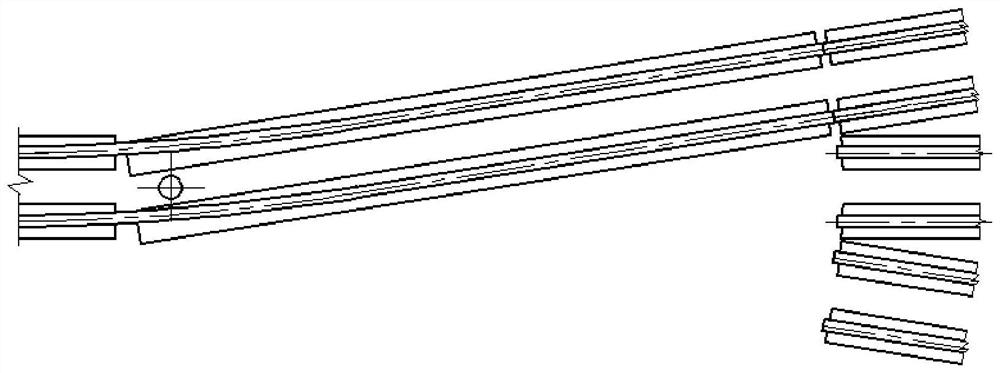

[0046] Such as Figure 1-2 shown in figure 1 In the structural schematic diagram of the suspended freight monorail three-opening turnout, the fixed monorail open box track beam a is two I-shaped beams ( Figure 1-2 Simplified in , the same below), the rotatable single-track open box-shaped track beam c is also two I-shaped beams arranged in parallel in space; the three-track open box-shaped track beam e is composed of six mutually fixed The two I-shaped girders in the center of the three-track open box track beam e are arranged in parallel in space; the two I-shaped girders on both sides are respectively arranged in parallel in space; the central I-shaped girder and the two sides The included angle between the I-shaped girders is just equal to the line change angle of the turnout. The two change-line rails g are respectively placed on the upper surface of the lower bottom plate inside the I-shaped girder (inside the vertical plate of the I-shaped girder) of the fixed monorai...

Embodiment 2

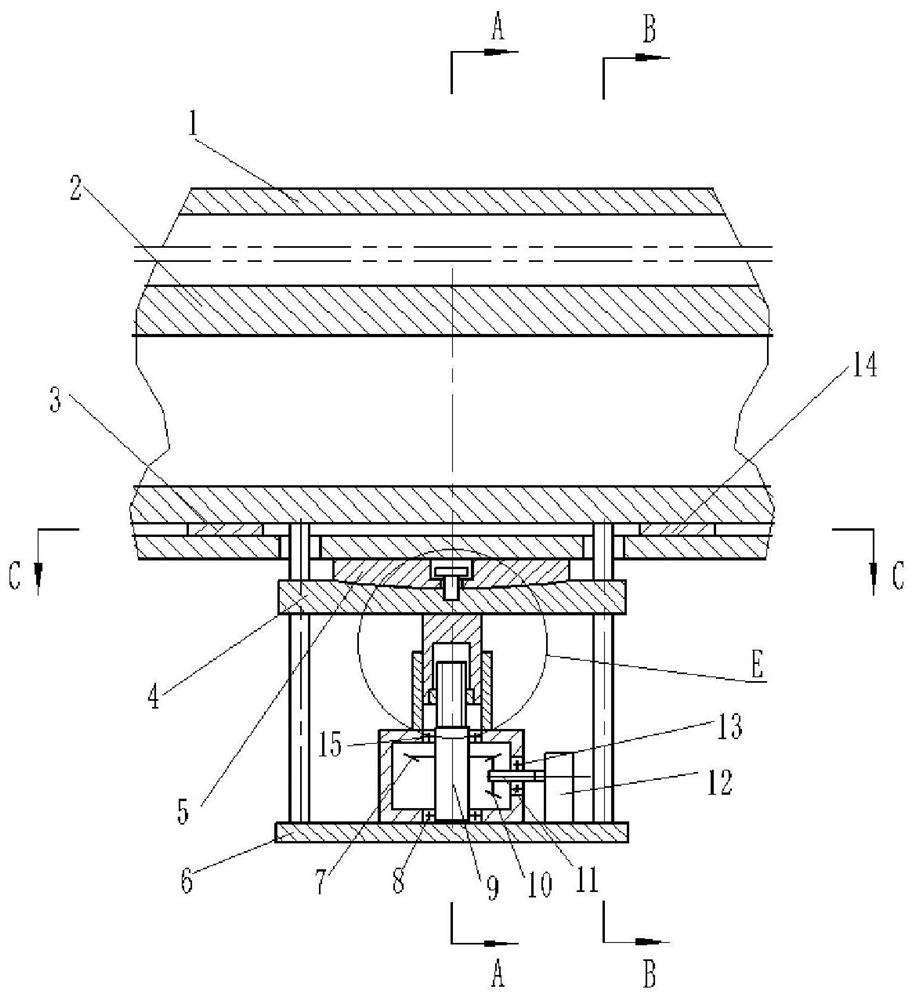

[0058] On the basis of Embodiment 1, the present invention also provides a working process of a suspension-type freight turnout rail follow-up rail locker, comprising the following steps:

[0059] Step 1. When it is necessary to change the line of the turnout rail, reversely start the hydraulic motor 12, and the output shaft of the hydraulic motor 12 rotates in the reverse direction, driving the transmission shaft 11, the small bevel gear 10, the large bevel gear 7, and the shaft screw 9 to rotate in reverse together ; Nut 18 and push rod 17 move downward in a straight line due to being restricted by the blocking pin shaft 24 and guide sleeve 19, and the lifting slide table 4 and locking plate 5 move downward together with the push rod 17 under the action of their own weight. Lock loose. The line-changing rail 2 can be changed as required. During the line-changing process of the line-changing rail 2, all components of the follow-up rail locking device (except the open box-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com