Self-adjusting plate shearing machine

A shearing machine and self-adjusting technology, applied in shearing machine equipment, shearing device, accessories of shearing machine, etc., can solve problems such as manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

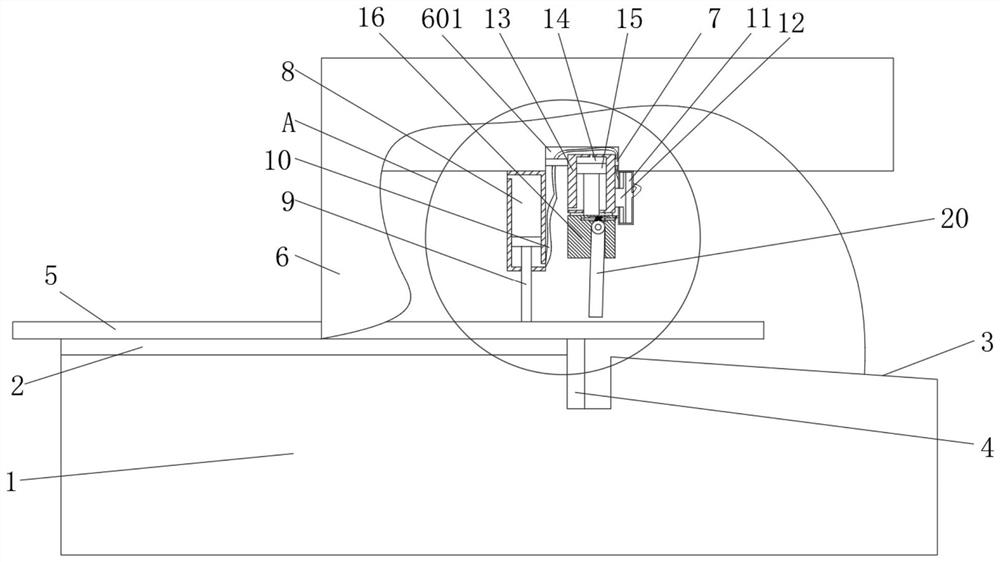

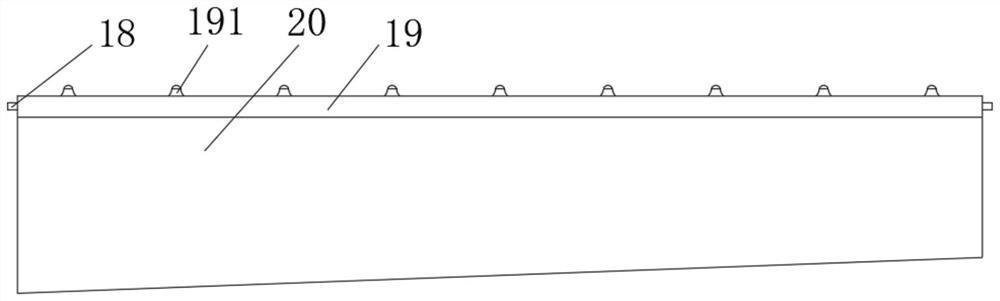

[0025] See Figure 1-7 A self-regulated shear machine, including the base 1, one side of the base 1, provided with the front seat 2, and the other side of the base 1 is provided with a tilted rear seat 3, and the front seat 2 is opened and the connection of the tilted rear seat 3 is opened. There is a knife slot, and a side wall of the tool groove is close to the front seat 2 is fixed to the lower blade 4, and the sheet 5 is placed on the front seat 2, and the upper portion of the base 1 is fixed to the upper base 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com