A casting furnace for metal casting which is convenient to move

A casting furnace and hardware technology, which is applied to casting equipment, furnaces, manufacturing tools, etc., can solve the problems of inconvenient grinding of cast iron components, inconvenient movement, inability to cool down hardware and external waste residue, etc., so as to facilitate the movement of cast iron furnaces and avoid high temperatures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

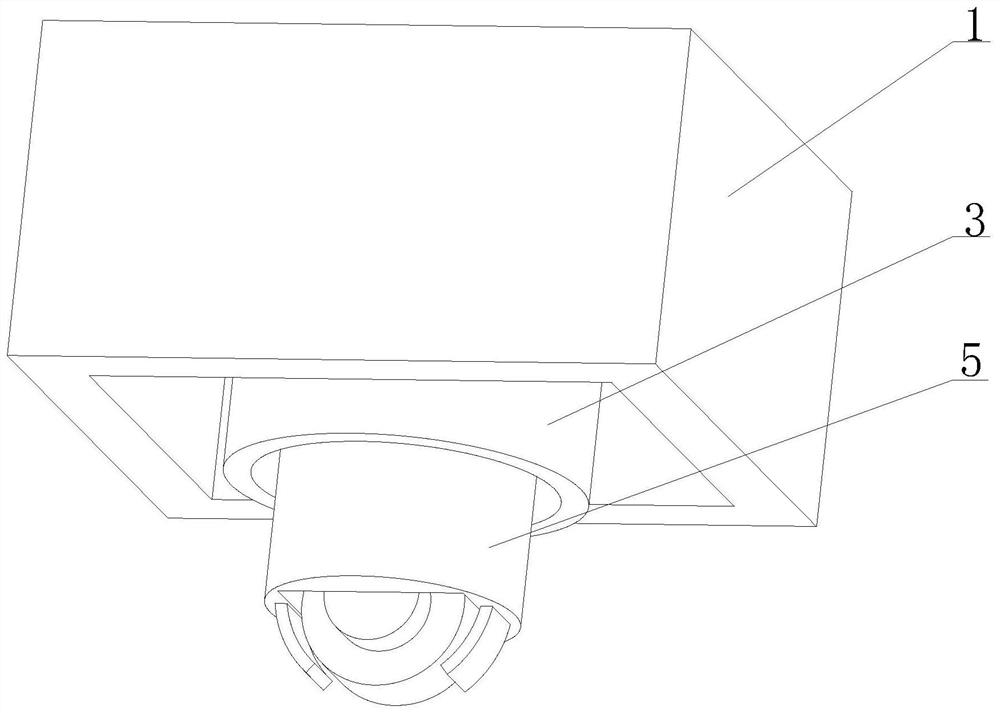

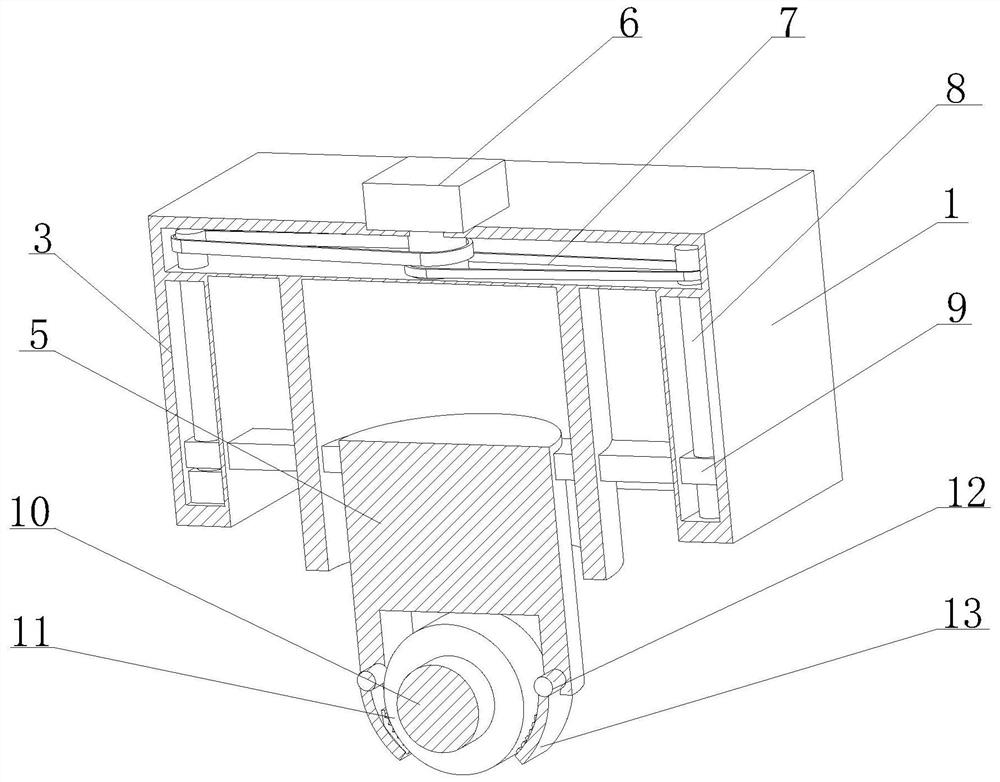

[0029] like figure 1 - Figure 5 As shown, the present invention provides a casting furnace for metal casting that is easy to move, comprising a base 1, the upper end of the base 1 is fixedly connected with a temperature insulating shell 2, the lower end of the base 1 is fixedly connected with a hydraulic support device 4, The lower end is provided with a fixed cylinder 3, the lower end of the fixed cylinder 3 is provided with a movable cylinder 5, the outer wall of the movable cylinder 5 is adapted to the inner wall of the set fixed cylinder 3, and the movable cylinder 5 slides with the fixed cylinder 3 through the set connecting support rod 9. Connection, the interior of the temperature insulating shell 2 is provided with a heating cylinder 21, the right end of the heating cylinder 21 is provided with a cooling filter cylinder 22, the lower end of the moving cylinder 5 is fixedly connected with a rotating shaft 10, and the outer wall of the rotating shaft 10 is provided with...

Embodiment 2

[0031] like Figure 2-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a nylon scraper 25 is fixedly connected to the inside of the heating cylinder 21, a groove is provided inside the cooling filter cylinder 22, and the inside of the groove is There is a transmission keel 27, the setting of the cooling filter keel 22 and the transmission keel 27 can facilitate the transmission of the finished casting, and the slag on the surface of the casting can be removed during the transmission process. The right end of the transmission keel 27 is provided with a A through hole 28, and the lower end of the through hole 28 penetrates the lower end of the cooling filter cartridge 22, the interior of the cooling filter cartridge 22 is provided with a condenser 26, and the right end of the condenser 26 is fixedly connected with a pipeline, and the lower end of the cooling filter cartridge 22 A through groove 29 is provided through, the through gro...

Embodiment 3

[0034] like Figure 1-5As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, the upper end of the base 1 is fixedly connected with a drive motor 6, and the lower end of the drive motor 6 is provided with a connecting shaft, and the base 1 The inner part of the shaft is provided with a rotating keel 8, the upper end of the rotating keel 8 is provided with a transmission belt 7, and the left end of the transmission belt 7 is sleeved on the outside of the connecting shaft; At the end, there are also two transmission belts 7, so that it is convenient to use one connecting shaft to drive the two rotating knuckles 8 to rotate at the same time.

[0035] Preferably, the upper end of the moving cylinder 5 is provided with a connecting support rod 9, the rotating knuckle 8 runs through the upper and lower ends of the connecting support rod 9, and the inner wall of the connecting support rod 9 is adapted to the provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com