Evanescent mode sand box three-dimensional compaction table

A technology for vibrating tables and molding sand boxes, which is applied in the direction of modeling tables, casting molding equipment, metal processing equipment, etc., can solve the problems of noise pollution, low efficiency, vibration and clamping are not firm, etc., to avoid interference, structure streamlined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

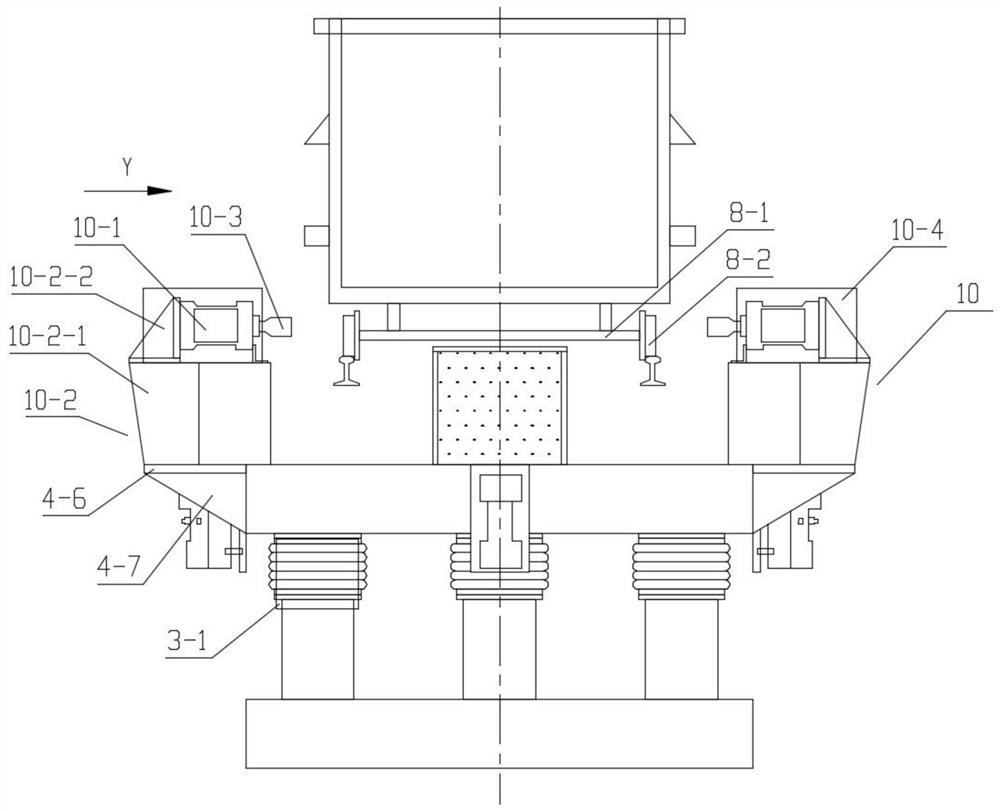

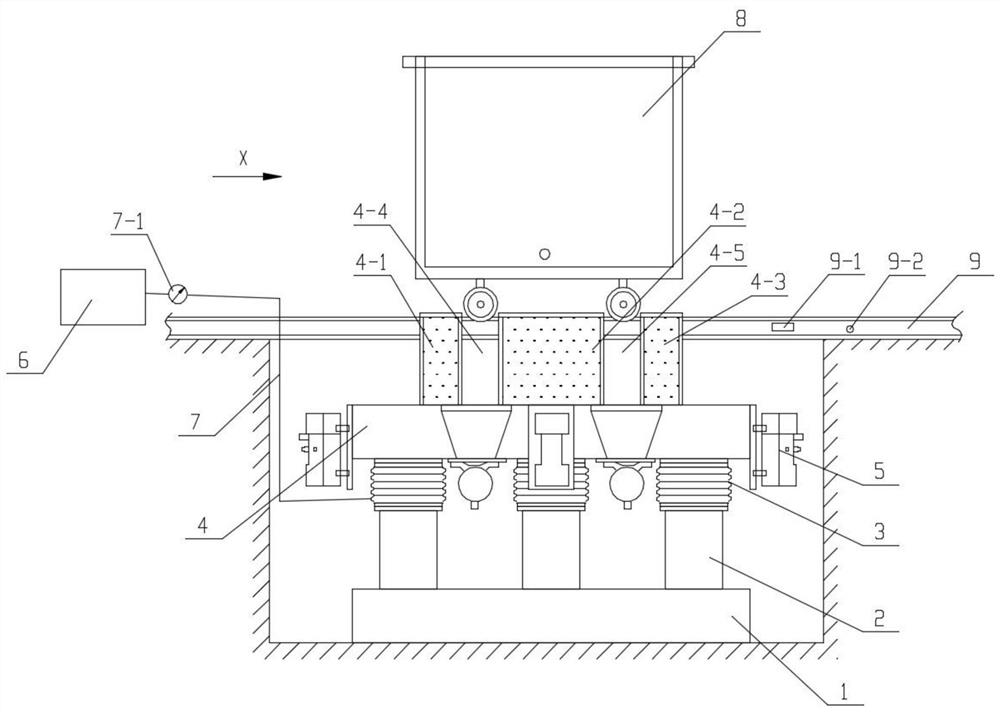

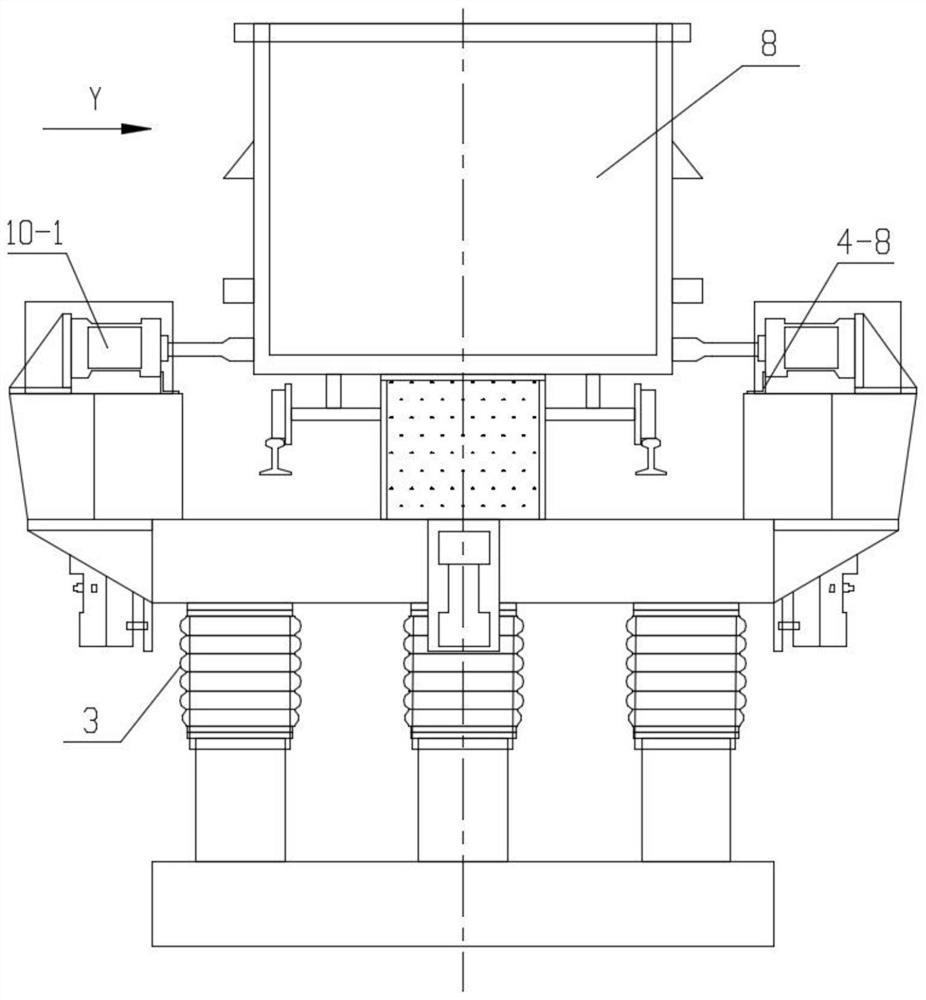

[0030] Such as Figures 1 to 3 In the one shown, the X-axis direction in the figure is the length direction of the sand box 8 to be vibrated, the vibrating table 4 and the sand box running track 9, and the Y-axis direction in the figure is the width of the sand box 8 to be vibrated and the vibrating table 4 direction, the three-dimensional vibrating platform of the sand box to be vibrated in the lost mode includes a base 1, several sets of pillars 2, several sets of air springs 3, a vibrating table 4, several sets of vibrating motors 5 and an air source 6, and several sets of pillars 2 are vertical It is arranged on the top surface of the base 1, and a group of air springs 3 are arranged on the top of each group of the pillars 2, and the vibrating table 4 is fixedly installed on the top surface of the air springs 3, and the vibrating table 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com